The Shootist

|

posted on 16/7/05 at 02:10 AM posted on 16/7/05 at 02:10 AM |

|

|

Plumbing solder should work OK..

but the best would be silver solder.

|

|

|

|

|

907

|

| posted on 16/7/05 at 08:21 AM |

|

|

IMHO

In 4th place, soft solder.

In 3rd place, silver solder.

In 2nd place, brazing. (brass)

But by far the easy option....

Nylon, with push in fittings.

It's whats used in industry to pipe up pneumatic rams etc.

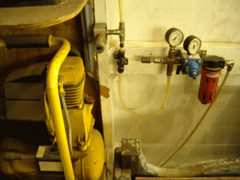

I have a loop of this in the roof of the garage with plug in points in various places.

Paul G

Rescued attachment air-com.gif

|

|

|

JonBowden

|

| posted on 19/7/05 at 08:15 AM |

|

|

I was messing about in the garden yesterday using a compressor to pressurise a plastic coke bottle then let it go like a rocket - good fun.

The bottle had no problem coping with 100 psi. I have heard that they will take 1000psi. This suggests that connecting loads together would work as a

resevoir.

Jon

|

|

|

indykid

|

| posted on 19/7/05 at 08:55 AM |

|

|

why not use compression fittings?

would that not be better if not slightly more expensive than using solder fittings?

let me know how you get on, as it's something i'd be interested in having a go at.

tom

|

|

|

davidwag

|

| posted on 19/7/05 at 08:51 PM |

|

|

Hi,

This is proper plastic push fit air line pipe.

https://secure.thorite.co.uk/Products_Snapline_tubing_239.html

Not much dearer that copper pipe. I think.

The plastic unions that go with it can be easily disconnected and re-used.

David

|

|

|

madman280

|

| posted on 21/7/05 at 12:41 AM |

|

|

Copper done correctly for air lines requires a bit of thought and skill but can be very nice. I've plumbed complete shop air supplies with

1/2" hard copper pipe and soldered joints. I'm quite good at soldering. I learned to solder properly (in very expensive silver no less) at

12 from my plumber Dad and Granddad so had lots of practice and good teachers. I water tested those systems to 250 psi for 2 days with no leaks.

Normal running presure is about 150 psi in most shops here. The rated max presure for M type annealed 1/2 copper pipe is 420psi. at 100 degree F. The

joints soldered with Sb5 alloy (95-5 Tin-Antimony) are rated to 1090 psi at full penetration. Be warned though Alloy Sn50 solder ( 50-50 Tin-Lead) is

only rated to 200psi. Be very careful with the solder type if using copper for air lines. A few point to help out. 1. clean the pipe and fitteing to

perfection. 2. use the proper flux and solder 3. heat the fitting and let the solder flow toward the heat

If you can weld a car together you most surely can solder copper pipe.

[Edited on 21/7/05 by madman280]

|

|

|

madman280

|

| posted on 21/7/05 at 12:46 AM |

|

|

Jon,

Carfull with them coke bottle experiments mate - you can put and eye out, knock off the neighbour cat or bust a gut laughing

[Edited on 21/7/05 by madman280]

|

|

|