timf

|

| posted on 5/11/03 at 04:49 PM |

|

|

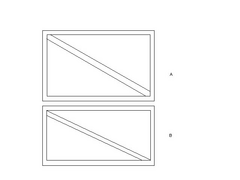

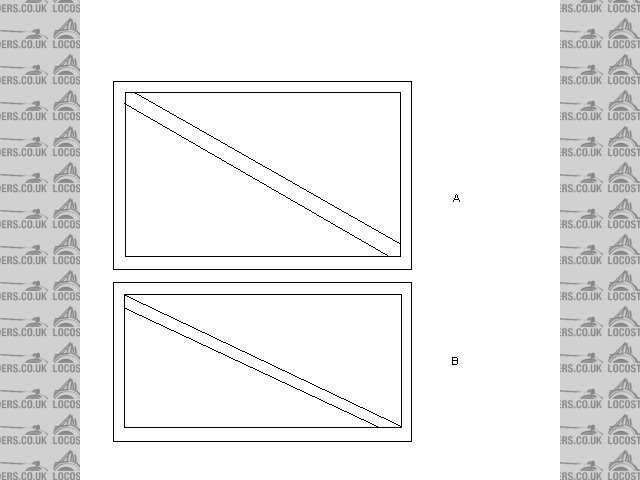

question for cymtriks

could you say what of the 2 methods of bracing is better in the attached drawing

in regards to stiffness or won't it make much difference

thanks Tim

[Edited on 5/11/03 by timf]

Rescued attachment bracing.jpg

|

|

|

|

|

Hellfire

|

| posted on 5/11/03 at 05:10 PM |

|

|

Strength

IMHO - either can be improved by welding parallel sections with the brace. Be it either top/bottom or left/right. Or if more than one brace, then

alternate the parallel's braced ie top/bottom then left/right.

Course I could be totally off the marqué...

|

|

|

kingr

|

| posted on 5/11/03 at 05:23 PM |

|

|

My guess would be that it would virtually the same stiffness, but B would fall down in strength. That and the fact the A looks better  . Hellfire -

I'm not sure I follow what you're say. . Hellfire -

I'm not sure I follow what you're say.

I await Cymtrik's expert reply with interest.

Kingr

|

|

|

Alan B

|

| posted on 5/11/03 at 05:25 PM |

|

|

A is better.....common centrelines non-offset loading

B is easier...and only minutely inferior

[Edited on 5/11/03 by Alan B]

|

|

|

craig1410

|

| posted on 6/11/03 at 01:07 PM |

|

|

I've done all mine as in "A" as I too thought it looked better and would ensure that the weld between the upright and the

longitudinal tube was further gussetted by the diagonal tube which should in my simple view be better as it will remove some localised stresses from

the weld. (Not that I'm worried about my welding you understand...)

Cheers,

Craig.

|

|

|

Alan B

|

| posted on 6/11/03 at 01:17 PM |

|

|

I've used mainly 'B' type joints, but I agree with your points...........my excuse is I'm a lazy git..

|

|

|

craig1410

|

| posted on 6/11/03 at 01:24 PM |

|

|

Alan,

Thanks.

I actually found the joints quite easy to make. I measured the diagonal angle with a piece of string and a protractor and measured the diagonal

distance with a steel rule. This allowed me to mark the required cut points at both ends which got chopped with a hacksaw. I then chopped the points

off the ends of diagonal piece to clear the existing fillet welds between the longitudinal and vertical tubes before welding in place. Easy peasy!!

When doing the opposite side of the car, then the piece of steel which you cut your first diagonal from will have the correct angle on it for the

other side already ready to be cut to length and trimmed to suit.

Cheers,

Craig.

|

|

|

JoelP

|

| posted on 6/11/03 at 01:42 PM |

|

|

i was going to have a stab at this question yesterday, though i'd leave it to someone who knows what they're on about, unlike me who just

guesses.

As craig and others point out, the gusset thingy strengthens the weld somewhat, so is probably better. Do people tend to do butt welds or 45 degree

things? I've done most of mine as butts and really its not very clever, should've spent some time getting it nice like others have. Then

type A bracing looks and feels better too as it further strengthens the weld.

Anyway that my tuppence...!

|

|

|

Alan B

|

| posted on 6/11/03 at 01:58 PM |

|

|

quote:

Originally posted by craig1410

Alan,

Thanks.

I actually found the joints quite easy to make. I measured the diagonal angle with a piece of string and a protractor and measured the diagonal

distance with a steel rule. This allowed me to mark the required cut points at both ends which got chopped with a hacksaw. I then chopped the points

off the ends of diagonal piece to clear the existing fillet welds between the longitudinal and vertical tubes before welding in place. Easy peasy!!

When doing the opposite side of the car, then the piece of steel which you cut your first diagonal from will have the correct angle on it for the

other side already ready to be cut to length and trimmed to suit.

Cheers,

Craig.

Hmmm?....that does sound easy.......

Easy is good...

Cheers

|

|

|

timf

|

| posted on 6/11/03 at 02:39 PM |

|

|

cheers for the replys guys

i'm also using the A method but was curious to see if there is any diffences in strength between them.

Tim

|

|

|

Hugh Paterson

|

| posted on 6/11/03 at 06:44 PM |

|

|

Arghhhhhhhhhhhhh

Roll on the day when my piggy bank has enough in it to buy a new tube notcher

Shug.

|

|

|

malcolmstoddart

|

| posted on 6/11/03 at 09:15 PM |

|

|

I would say that A would be better in that, there is more weldable area on the ends of the diagonal and the angles are equal.Better still... if you

can gusset the corners out - stronger again.

|

|

|

timf

|

| posted on 7/11/03 at 09:34 AM |

|

|

quote:

Originally posted by Hugh Paterson

Roll on the day when my piggy bank has enough in it to buy a new tube notcher

Shug.

i got this from the states last time i was over there

$104.00

works out about £62 without shipping

see http://www.jegs.com/cgi-bin/ncommerce3/ProductDisplay?prrfnbr=120357&prmenbr=361

[Edited on 7/11/03 by timf]

|

|

|

MikeR

|

| posted on 7/11/03 at 12:49 PM |

|

|

hmmm, but what if you want to cut a 46 degree angle ????

(joke)

|

|

|

Alan B

|

| posted on 7/11/03 at 01:13 PM |

|

|

Mike, I have one.....or at least similar....you can set them for any angle (within reason of course)....

For round they are almost essential.

|

|

|

timf

|

| posted on 7/11/03 at 01:44 PM |

|

|

quote:

Originally posted by Alan B

For round they are almost essential.

agree tried it out on some erw round to mock up wishbones and the joints are superb

|

|

|

Hugh Paterson

|

| posted on 7/11/03 at 08:21 PM |

|

|

Tube Notching

Yup, agreed they are not too bad, we have one as well, I was thinking of one of the electric linisher type of notchers. Out of curiosity what type of

cutter are u using, we find that ours eats em. Methinks we have been using cheap guff though

Shug.

|

|

|

JoelP

|

| posted on 7/11/03 at 09:04 PM |

|

|

do you mean the device that cuts 'fishmouth' thingys, using some sort of holesaw? I was trying to get one of those cos i saw a build site

with some brilliant results from one.

|

|

|

Alan B

|

| posted on 7/11/03 at 10:23 PM |

|

|

quote:

Originally posted by Hugh Paterson

Yup, agreed they are not too bad, we have one as well, I was thinking of one of the electric linisher type of notchers. Out of curiosity what type of

cutter are u using, we find that ours eats em. Methinks we have been using cheap guff though

Shug.

The two main things....keep it as rigid as possible (oo er missus).....run it quite slowly......oh Ok 3 things...use a bit of lube

I also found that if you are cutting several with plain 90 degree notches then I would just put a full length of tube on the pillar drill, centre

punch centres and the go right through with the pilot and holesaw and do two notches at once...a lot smoother, and faster, than the single end

method....oh, yeah saves sawing too..

|

|

|

Alan B

|

| posted on 7/11/03 at 10:25 PM |

|

|

quote:

Originally posted by JoelP

do you mean the device that cuts 'fishmouth' thingys, using some sort of holesaw? I was trying to get one of those cos i saw a build site

with some brilliant results from one.

Yep....did all my buggy with one..

http://www.desicodesign.com/Calabrina/

|

|

|

sgraber

|

| posted on 8/11/03 at 12:12 AM |

|

|

Ok, this thread is getting slighty off-topic. But anyways here are two programs that will make your fishmouth lives easier.

WinMiter

ftp://ftp.ihpva.org/pub/software/winmiter/

EZ Pipe - software for pipe welding patterns

http://www.ezpipe.com/

I haven't used EZ Pipe personally, but winmiter is excellent. It's shareware.

Later,

Graber

Steve Graber

http://www.grabercars.com/

"Quickness through lightness"

|

|

|

cymtriks

|

| posted on 10/11/03 at 11:25 PM |

|

|

I've finally noticed this thread!

Sorry to be a bit late guys.

Alan sums it up very well in his first response. A is theoretically better and looks better. B is only slightly inferior in practice and is probably

easier to assemble.

|

|

|