Ivan

|

| posted on 18/3/07 at 03:24 PM |

|

|

Spring rate - everyone's wrong but me

Hi all

I am mystified by something that’s happened – everything I’ve read tells me that for a slanting shock like on the Locost you have an effectively

“falling rate” spring.

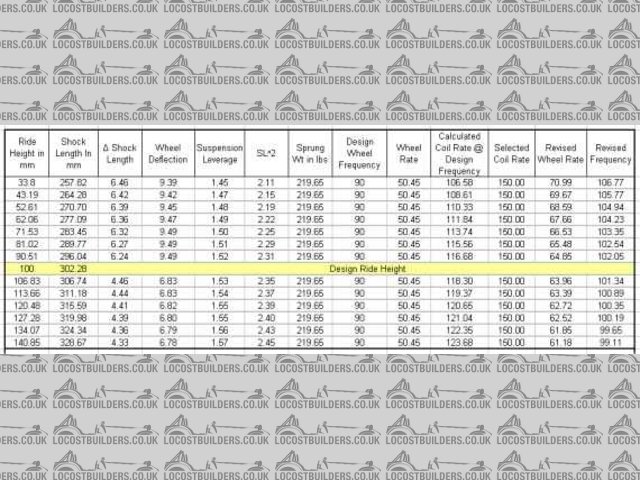

I’ve just plotted out my suspension on cad at a ride height that rises from 33.8 mm (full bounce)

to 140.85 mm (full droop) and got totally the opposite – a rising rate as the wheel moved upwards from a wheel frequency of 99.11 at full droop of the

wheel to 106.77 at full bounce of the wheel.

When I think about it the result makes sense even though it is totally contrary to common understanding as the angle between the spring and the lower

control arm opens up as the wheel moves upwards - the normal requirement for a rising rate suspension.

Has anybody else done this exercise – if so did they get the same result or am I going wrong somewhere in my calculation. Below is a print of my

spreadsheet.

Spring Rate Calculation

HELP – ANYBODY KNOW WHERE I’VE GONE WRONG – please excuse the shouting but it’s driving me mad

|

|

|

|

|

Bob C

|

| posted on 18/3/07 at 03:26 PM |

|

|

No you're not the only one - I was afflicted with the same prejudice, til I did the sums.....

cheers

Bob

|

|

|

flak monkey

|

| posted on 18/3/07 at 03:35 PM |

|

|

Draw it out as a triangle:

Make the hypotenuse the spring rate and the adjacent the upward wheel force.

The spring rate is constant, say 250lb/inch.

As the angle increases the upward force decreases.

Eg:

250cos15 = 241lb

250cos25 = 226lb

250cos40 = 191lb

So the effective spring rate falls. Or have i missed something?

David

[Edited on 18/3/07 by flak monkey]

Sera

http://www.motosera.com

|

|

|

gazza285

|

| posted on 18/3/07 at 04:03 PM |

|

|

As the wheel deflects the angle between the shock and bottom arm moves towards a right angle, leading to a rising rate. However the angle of the

bottom arm moves away from a right angle (assuming that the arm is horizontal at rest) in relation to the wheel movement, giving a falling rate, and

the two together to get whether yours is rising, falling or static.

DO NOT PUT ON KNOB OR BOLLOCKS!

|

|

|

Bob C

|

| posted on 18/3/07 at 04:28 PM |

|

|

Aye - you've to do a DETAILED analysis of ALL the factors in YOUR geometry to be accurate - mine was near enough linear, slightly rising, I was

happy ;^)

Bob

I've remembered how I did it - I modelled a front corner in solidworks & measured the shock length versus vertical deflection.- it was long

long ago & I've lost the data

[Edited on 18/3/07 by Bob C]

|

|

|

flak monkey

|

| posted on 18/3/07 at 04:33 PM |

|

|

Ahh, fair enough

I believe you

Sera

http://www.motosera.com

|

|

|

Ivan

|

| posted on 18/3/07 at 04:38 PM |

|

|

Yes - I also modeled the suspension in TurboCad - did a radial copy every X degrees and measured the spring length against rise in the lower ball

joint to give the results above.

An interesting point was that a small change in the location of the lower spring bracket made a huge change in spring required for any specific wheel

rate making spring comparisons between different homebuilts almost pointless.

|

|

|

JB

|

| posted on 18/3/07 at 04:51 PM |

|

|

quote:

An interesting point was that a small change in the location of the lower spring bracket made a huge change in spring required for any specific wheel

rate making spring comparisons between different homebuilts almost pointless.

Which is exactly why we should all talk in wheel rates, and not spring rates.

[Edited on 18/3/07 by JB]

|

|

|

Ivan

|

| posted on 18/3/07 at 05:08 PM |

|

|

quote:

Originally posted by JB

Which is exactly why we should all talk in wheel rates, and not spring rates.

[Edited on 18/3/07 by JB]

And get our suspension exactly symmetrical - left and right

|

|

|

t.j.

|

| posted on 18/3/07 at 06:45 PM |

|

|

hmmmm,

I want that calcu-programma too

Never calculated springs, but i have to before I hit the road.

So any recommendations on the internet?

grtz Theo

|

|

|