Angel Acevedo

|

| posted on 25/7/17 at 01:01 AM |

|

|

Upper Wishbone Design.

To the collective,

I am fabricating my wishbones, front only as I´ll be running a Live Axle in the back.

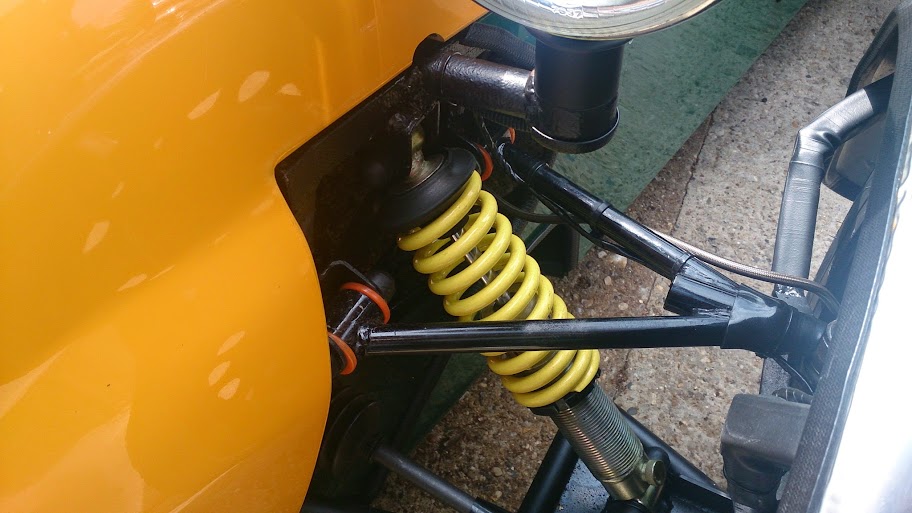

I was going to go with this first....

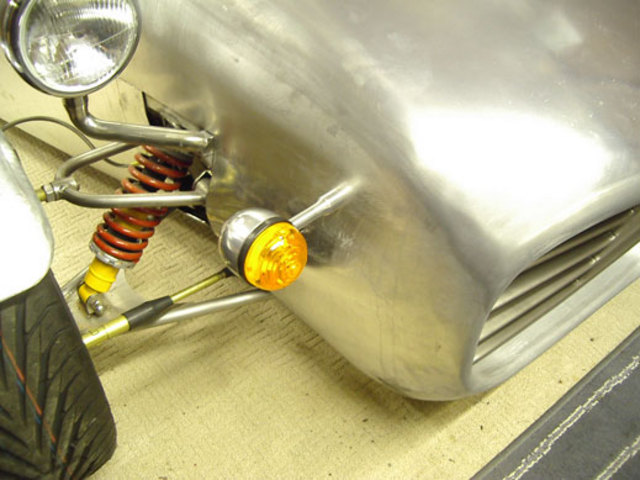

But found angle was a little bit extreme at the weld to the threaded insert, then I decided to use this approach even though I am using Top Hat

bushings instead of Rod Ends.

Question is:

- Are there any considerations against doing so?

I don´t have to comply with IVA or SVA or the like

Also, I will have only full turn adjustment on Camber and pretty much Fixed Caster. Considering 11" (275 mm) distance between lower and upper

balljoints, and fine threads on the Track Rod End used as Upper Balljoint, I get about 5° for 1" (25 mm) full travel which leads to 0.25° per

turn Camber adjustment.

I don´t see it being a problem, Do you? if so, could you ellaborate?

Thanks in advance

Edited to give credits on pics...

Sorry for the blatant plagiarism to the pictures shown...

First one posted by Stot second one by Fred W B

[Edited on 7/25/2017 by Angel Acevedo]

Beware of what you wish.. for it may come true....

|

|

|

|

|

907

|

| posted on 25/7/17 at 06:54 AM |

|

|

I made mine with a curved design because it seems to "fit" around the spring

and in my opinion looks better.

Make sure you make them with enough castor.

Paul G

Rescued attachment winker-015-s.jpg

|

|

|

43655

|

| posted on 25/7/17 at 10:20 AM |

|

|

do you really need camber adjust? Could you not use inline rod ends, or shims?

You'll get a stronger, lighter wishbone if you keep the forces between balljoints inline

|

|

|

Jenko

|

| posted on 25/7/17 at 10:56 AM |

|

|

[Edited on 25/7/17 by Jenko]

MY BLOG - http://westfieldv8.blogspot.co.uk/

|

|

|

Angel Acevedo

|

| posted on 25/7/17 at 03:23 PM |

|

|

quote:

Originally posted by 43655

do you really need camber adjust? Could you not use inline rod ends, or shims?

You'll get a stronger, lighter wishbone if you keep the forces between balljoints inline

Camber adjustment will be made through thread of Upper Ball Joint Shaft (??)

I will not be using ball Joints on the Chassis Pivots, I´m using Bushings.

My question is regarding the manner pipes are joined together.

On the first example, there are only 2 pipes per wishbone.

On the second there are four, but angles coming into the threaded tube where the Upper Ball Joint will screw in, have a less acute angle, therefore

easier to cut, fit and weld.

I decided to go this route.

Beware of what you wish.. for it may come true....

|

|

|

alfas

|

| posted on 25/7/17 at 03:57 PM |

|

|

design on first pic is imo much better in terms of strength

|

|

|

JoelP

|

| posted on 25/7/17 at 08:08 PM |

|

|

First picture is better. Second just has more cuts, more welds, and is harder to make. Its only done that way to allow threaded rod ends to be used.

|

|

|

Angel Acevedo

|

| posted on 26/7/17 at 01:48 AM |

|

|

quote:

Originally posted by JoelP

First picture is better. Second just has more cuts, more welds, and is harder to make. Its only done that way to allow threaded rod ends to be used.

Decided to go this route..

I was halfway through the pipe cutting and decided to end up with fewer welds...

So started from scratch and cut four long pipes to do first design.

Thanks all for your comments.

AA

Beware of what you wish.. for it may come true....

|

|

|