Slimy38

|

| posted on 10/11/13 at 11:17 AM |

|

|

Welding an insert into a tube

I have some threaded inserts for my suspension, but I'd like to reinforce them by welding them into some tubing. What's the best way to do

it? Logic would suggest the only place they can be welded is on the end, but I'm wondering whether that will actually be weaker than simply

using the inserts as they are. They are to be used for the adjusters, so I believe the forces will be pulling and pushing. Does that mean I might

simply pull the adjusters straight out the tube?

Any thoughts?

[Edited on 10/11/13 by Slimy38]

|

|

|

|

|

theprisioner

|

| posted on 10/11/13 at 11:46 AM |

|

|

One possible solution I have used several times. I drill one or possibly 2 (is better) 8mm holes in the side of the tube and spot weld the insert to

the tube then remove excess weld afterwards.

http://sylvabuild.blogspot.com/

http://austin7special.blogspot.co.uk/

|

|

|

omega 24 v6

|

| posted on 10/11/13 at 11:46 AM |

|

|

Drill the tube sides and plug weld them.

If it looks wrong it probably is wrong.

|

|

|

doobrychat

|

| posted on 10/11/13 at 11:47 AM |

|

|

slice the top and bottom of the tube.. weld insert on the end then the 2 sliced area to support top and bottom the length of the insert.. I did this

when i converted my top wishbones to take rose joints..

|

|

|

CNHSS1

|

| posted on 10/11/13 at 11:55 AM |

|

|

yup, +1 from me. weld the seam as you mentioned, then plug weld a couple of holes as above

"Racing is life, everything else, before or after, is just waiting"---Steve McQueen

|

|

|

Slimy38

|

| posted on 10/11/13 at 01:24 PM |

|

|

Holes it is then!  I just hope I don't end up going through the insert, I don't fancy having to clean up the threads afterwards. I just hope I don't end up going through the insert, I don't fancy having to clean up the threads afterwards.

Thank you all.

|

|

|

MikeRJ

|

| posted on 10/11/13 at 02:36 PM |

|

|

quote:

Originally posted by Slimy38

Holes it is then!  I just hope I don't end up going through the insert, I don't fancy having to clean up the threads afterwards. I just hope I don't end up going through the insert, I don't fancy having to clean up the threads afterwards.

Thank you all.

If you weld a threaded insert then the chances are high that you will need to run a tap through it afterwards.

Are these inserts for the wishbones or trailing arms so you can install rod ends for adjustment? If so, how were you planning to fix them in without

welding (i.e. "using the inserts as they are" )?

[Edited on 10/11/13 by MikeRJ]

|

|

|

Mistron

|

| posted on 17/11/13 at 10:10 PM |

|

|

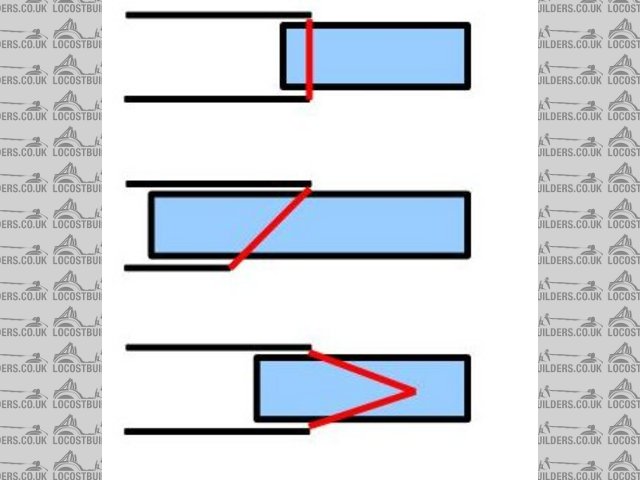

It's better practice to cut the end of the tube at 45 degrees and weld round the cut as it gives a larger contact area and also spreads the load

along the length of the bush, rather than concentrating it all around the bus at one point in its length

Al

|

|

|

iank

|

| posted on 18/11/13 at 08:07 AM |

|

|

quote:

Originally posted by Mistron

It's better practice to cut the end of the tube at 45 degrees and weld round the cut as it gives a larger contact area and also spreads the load

along the length of the bush, rather than concentrating it all around the bus at one point in its length

Al

Even better to make two cuts as you get more weld on both sides of the insert.

Description

--

Never argue with an idiot. They drag you down to their level, then beat you with experience.

Anonymous

|

|

|

Slimy38

|

| posted on 18/11/13 at 10:14 AM |

|

|

quote:

Originally posted by MikeRJ

Are these inserts for the wishbones or trailing arms so you can install rod ends for adjustment? If so, how were you planning to fix them in without

welding (i.e. "using the inserts as they are" )?

[Edited on 10/11/13 by MikeRJ]

They are for rod ends, so yes they would have been welded anyway. I just meant either welded up as they are, or welded inside tubes which are then

used to make up the wishbones.

|

|

|