FuryRebuild

|

| posted on 30/6/12 at 03:01 PM |

|

|

Fury chassis gussets - do you have deisgn suggestions?

So, before I go off to cad and get cut a set of gussets to brace the joints in my fury, both on the original chassis and with my modifications, does

anyone have any designs or suggestions ?

Needless to say the plan will be to lighten them with holes in the middle as well, and probably use 2mm mild steel as well.

Your thoughts?

When all you have is a hammer, everything around you is a nail.

www.furyrebuild.co.uk

|

|

|

|

|

DIY Si

|

| posted on 30/6/12 at 03:05 PM |

|

|

If you do lighten them, do your best to then get the holes rounded through. I can't think of the proper term for it though, but it's where

the lip of the hole is turned down. Otherwise, don't bother with the lightening as you won't save much but may loose a lot of the

strength.

“Let your plans be dark and as impenetratable as night, and when you move, fall like a thunderbolt.”

Sun Tzu, The Art of War

My new blog: http://spritecave.blogspot.co.uk/

|

|

|

FuryRebuild

|

| posted on 30/6/12 at 03:11 PM |

|

|

Hi Si

Yes - that was going to be the plan - not sure if the laser cutters can do anything about that, but I remember Carroll Smith having some very strong

opinions on the subject. It would be easy enough to do in a mill i expect, with a chamferring tool.

When all you have is a hammer, everything around you is a nail.

www.furyrebuild.co.uk

|

|

|

clairetoo

|

| posted on 30/6/12 at 03:17 PM |

|

|

If you get the tubes in the right place , why do you need gussets ?

Its cuz I is blond , innit

Claire xx

Will weld for food......

|

|

|

FuryRebuild

|

| posted on 30/6/12 at 03:22 PM |

|

|

Hi Claire

I've been thinking that as well - surely if the force goes into the right places, and that's what a spaceframe is all about then why do

this?

Research seems to say that a gusset strengthens the joint, and on my fury there are certainly places where force is fed into empty, non cross braced

squares and it's not necessarily possible to get a diagonal in there. In a case like this, a gusset seems appropriate.

I'm also putting 215 bhp into my chassis, with quaife box and diff. This is fairly much at the limit of what the chassis can handle without

extra strengthening.

When all you have is a hammer, everything around you is a nail.

www.furyrebuild.co.uk

|

|

|

clairetoo

|

| posted on 30/6/12 at 03:32 PM |

|

|

I think you will find there are a lot of 200+ bhp Fury's out there running un-modified chassis.......mine is running around 208 , and the only

mods I have done is to add some bracing across the front and up to the front corners (to stop the front top wishbone mounts cracking)

Its cuz I is blond , innit

Claire xx

Will weld for food......

|

|

|

FuryRebuild

|

| posted on 30/6/12 at 03:35 PM |

|

|

I think the section you've mentioned is one that's definitely in need of help and the photos I've seen of the most recent chassis

certainly seem to have a lot of support there.

By the way, my statement was based on original chats with Mark Fisher, back in the day. His view was that 200 was getting near the limits of what it

could handle.

[Edited on 30/6/12 by FuryRebuild]

When all you have is a hammer, everything around you is a nail.

www.furyrebuild.co.uk

|

|

|

clairetoo

|

| posted on 30/6/12 at 03:51 PM |

|

|

The front corners are definitely a weak point - I found both side of mine to be cracked right where they join the upright !

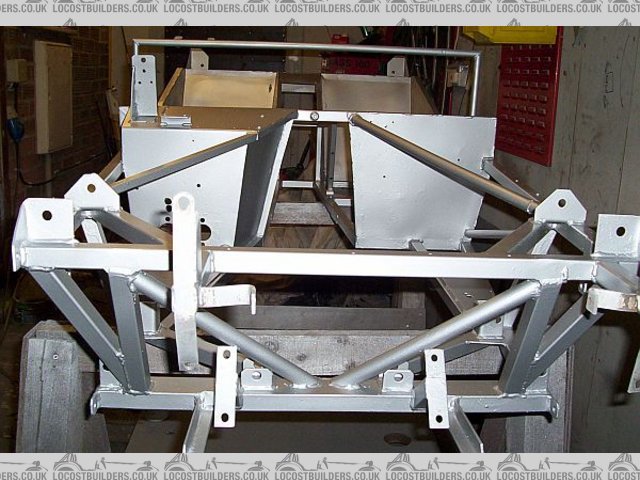

I added four tubes in a `W' - seen here on another V6 Fury I did .

Its cuz I is blond , innit

Claire xx

Will weld for food......

|

|

|

FuryRebuild

|

| posted on 30/6/12 at 03:56 PM |

|

|

That's a good looking v6. I don't recognise it.

And thanks for digging the photo out.

I like the design of the top left gusset in this picture - if it works out to be a similar weight (or less) to cross bracing the front with tubes, I

may cut my single tube out and cad and cut one like this.

When all you have is a hammer, everything around you is a nail.

www.furyrebuild.co.uk

|

|

|

clairetoo

|

| posted on 30/6/12 at 04:14 PM |

|

|

Thats a Mazda KL V6 - same as in mine

I'm not keen on gussets in place of tubes - a gusset has no compression strength at all , and will be limited in shape by other components - the

central `V' in that chassis is set back at the bottom (to pass the rack mounts , which are allso welded to the tubes)

I found a better picture as well

Its cuz I is blond , innit

Claire xx

Will weld for food......

|

|

|

JekRankin

|

| posted on 30/6/12 at 06:36 PM |

|

|

Newer Fury chassis have a bracing tube between the steering rack mounts which might be something to consider if you don't have one?

Jek

|

|

|

DIY Si

|

| posted on 30/6/12 at 08:39 PM |

|

|

Ah, now I see a pic of what you're thinking of, I'd go with Claire and use tube. Gussets are only of use to strengthen joints rather than

to replace tubes themselves. And the tubes will be much stiffer, and about the same to fabricate and fit.

“Let your plans be dark and as impenetratable as night, and when you move, fall like a thunderbolt.”

Sun Tzu, The Art of War

My new blog: http://spritecave.blogspot.co.uk/

|

|

|

FuryRebuild

|

| posted on 1/7/12 at 09:11 AM |

|

|

Hi Jek

I triangulated my rack-mounts town to the chassis fairly early on, at the same time I moved over to a quick-rack. I don't think tube between the

mounts is the correct solution - each time a horizontal load is fed in, the tube just moves it over to the other mount and the welds where the mount

meets the chassis are subject to possibly more stress than before.

and yes, tube where tube should be, rather than gussets.

Still, there's plenty to gusset nonetheless.

When all you have is a hammer, everything around you is a nail.

www.furyrebuild.co.uk

|

|

|

907

|

| posted on 1/7/12 at 11:32 AM |

|

|

As far as gussets go, these are pleasing to the eye. (IMHO)

Paul G

Description

|

|

|

FuryRebuild

|

| posted on 1/7/12 at 11:36 AM |

|

|

That fails to be ugly on many levels.

When all you have is a hammer, everything around you is a nail.

www.furyrebuild.co.uk

|

|

|

iank

|

| posted on 1/7/12 at 11:58 AM |

|

|

quote:

Originally posted by FuryRebuild

Hi Si

Yes - that was going to be the plan - not sure if the laser cutters can do anything about that, but I remember Carroll Smith having some very strong

opinions on the subject. It would be easy enough to do in a mill i expect, with a chamferring tool.

I believe these are the correct tool for the job (don't know if a chamferring tool turns a lip out or just rounds the edge)

http://www.motorsport-tools.com/sheet-metal-tools-punch-swage-tools-c-18059_18071.html

--

Never argue with an idiot. They drag you down to their level, then beat you with experience.

Anonymous

|

|

|

DIY Si

|

| posted on 1/7/12 at 12:22 PM |

|

|

That's the thing! Couldn't find a link when I was looking.

“Let your plans be dark and as impenetratable as night, and when you move, fall like a thunderbolt.”

Sun Tzu, The Art of War

My new blog: http://spritecave.blogspot.co.uk/

|

|

|

FuryRebuild

|

| posted on 1/7/12 at 01:13 PM |

|

|

Hmmm. It's not a chamfering tool though. There are cut-through chamfering tools out there.

When all you have is a hammer, everything around you is a nail.

www.furyrebuild.co.uk

|

|

|

DIY Si

|

| posted on 1/7/12 at 02:47 PM |

|

|

Why would you want a chamfer on what is likely to be 16 SWG sheet? A nicely swagged/flared hole will add a noticeable amount of stiffness to any

panel. But the tools aren't cheap.

“Let your plans be dark and as impenetratable as night, and when you move, fall like a thunderbolt.”

Sun Tzu, The Art of War

My new blog: http://spritecave.blogspot.co.uk/

|

|

|

Bare

|

| posted on 1/7/12 at 04:56 PM |

|

|

Effective gussets should not taper to a point. Or be welded/attached there.

Imagine a triangle piece with a sizable hole piece being removed from it's apex. .. that's the proven shape.

That works passably.. IF you must use gussets.

|

|

|