RMarine

|

| posted on 20/9/09 at 10:41 PM |

|

|

radiator pipes and welding???????

hi, i have been looking at possible way to piping up the cooling system pipes. so i dont have loads of rubber pipes everywhere i was thinging about

using large bore copper pipes, say 54mm or some stainless steel tube say 48mm. is this the bad idea? if so, why? or has anyone got a cheap way of

doing it ? and can you weld stainless steel in the same way as steel ....... Thanks

[Edited on 20/9/09 by RMarine]

[Edited on 20/9/09 by RMarine]

|

|

|

|

|

blakep82

|

| posted on 20/9/09 at 11:11 PM |

|

|

it can be done. ali is common, stainless also. stainless steel can be done with mig welding, you can use stainless wire, or even normal mig wire (but

the weld can rust a little i think) not sure what gas you'd use. argon i think

but yeah, not a terrible idea, and it can be done

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

UncleFista

|

| posted on 20/9/09 at 11:21 PM |

|

|

You can weld stainless just like mild steel, you'll need stainless wire and an argon mix gas.

If you want really cheap (like me) you can just use mild steel pipe, it doesn't rust due to the antifreeze and it looks OK once painted.

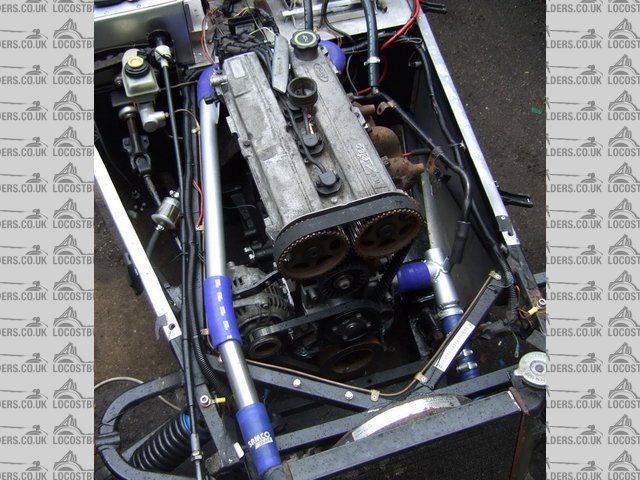

top view, hoses done

Tony Bond / UncleFista

Love is like a snowmobile, speeding across the frozen tundra.

Which suddenly flips, pinning you underneath.

At night the ice-weasels come...

|

|

|

MakeEverything

|

| posted on 21/9/09 at 06:34 AM |

|

|

A. It looks a hell of a lot tidier

B. It will radiate some of the heat as well

C. It wont leak or split as often as rubber

Kindest Regards,

Richard.

...You can make it foolProof, but youll never make it Idiot Proof!...

|

|

|

londonsean69

|

| posted on 21/9/09 at 08:04 AM |

|

|

There are places that also sell nice shiny Ally pipes and pipe bends for this purpose.

Ally (especially thin) can be a pig with a MIG welder, better to TIG it

The intercooler pipes usually have a bead on the end to stop the hose popping off under pressure.

I think if it is for a radiator it should be OK without the beading, although no guarantees.

I intend doing mine with shiny ally straight bits and nice silicone bends

Sean

|

|

|

turbodisplay

|

| posted on 21/9/09 at 09:41 AM |

|

|

I used steam pipe from pts, with pipe bends to make mine, thick pipes, so a tad heaver than using thinner stainless.

I arc welded the pipes, then painted, no leaks first time

Darren

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

BenB

|

| posted on 21/9/09 at 11:04 AM |

|

|

You can use copper pipe (advantage= cheap and lots of right angles, 45 degree bends available). Not very light though!

Ali is better but expensive. Mild steel can be okay if you can find stuff with a thin-enough wall....

|

|

|

nick205

|

| posted on 21/9/09 at 11:15 AM |

|

|

Copper pipe + solder ring fittings are a doddle to use for this kind of thing. Not the lightest solution, but then not exactly heavy in the overall

scheme of things.

The choice of solder ring fittings, 45, 90, T & straight make it simple to construct the system and fitting a straight fitting on the ends where

the hoses attach gives you a ready made bead to keep the hose in place.

Once you've built the pipe work the copper can be painted quite easily to give a more aesthetic finish to the engine bay.

|

|

|

NS Dev

|

| posted on 21/9/09 at 11:57 AM |

|

|

quote:

Originally posted by turbodisplay

I used steam pipe from pts, with pipe bends to make mine, thick pipes, so a tad heaver than using thinner stainless.

I arc welded the pipes, then painted, no leaks first time

Darren

I use stainless pipe but go for hygienic tubing, its cheap enough and thinner, easy to weld

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

MakeEverything

|

| posted on 24/9/09 at 08:40 PM |

|

|

quote:

Originally posted by nick205

Once you've built the pipe work the copper can be painted quite easily to give a more aesthetic finish to the engine bay.

.... Or polished......

Kindest Regards,

Richard.

...You can make it foolProof, but youll never make it Idiot Proof!...

|

|

|