Another engine Mount Question - nut access

davidosullivan - 31/12/07 at 01:09 PM

Hi Guys,

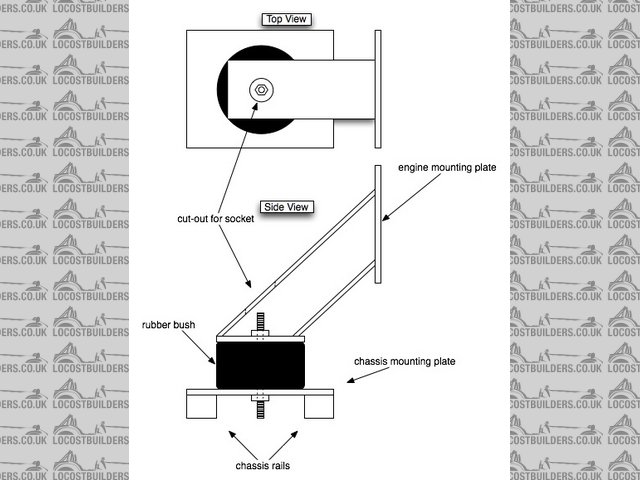

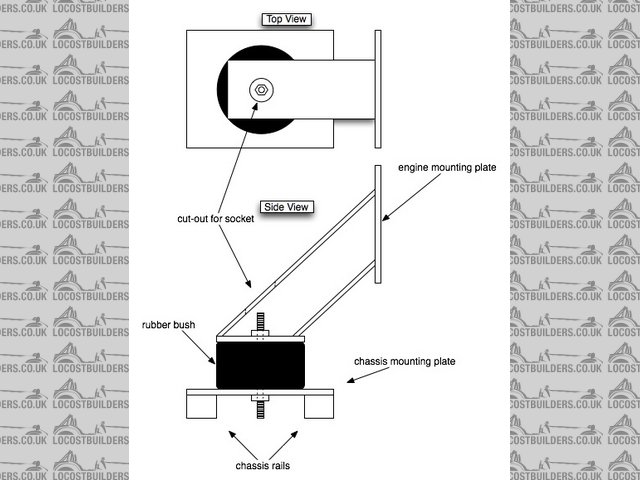

I'm in the middle of making my own engine mounts and was looking at the fixings for the rubber mount/bush.

I'd rather have access to the nut than weld one into the engine mount. Does anyone see any problems in cutting a hole in the engine mount (as

pictured... hopefully) to allow me to get a socket in.

[edit]... I should have put this on the diagram the main support is made out of 2" round steel tube.[edit]

Any help thanks.

David

EngineMountDiagram

[Edited on 31/12/07 by davidosullivan]

big_wasa - 31/12/07 at 01:40 PM

Looks fine to me.

You will want a drain hole to let water out.

I did mine like this

tks - 31/12/07 at 02:49 PM

i woud do it another way, maybe its overkill..

i would weldin a bushe with tig.

Then the forces are devided into the 2 walls of the tubeing and not only on the plane side wich touche the rubber. you then have as much acces to your

nut as possible.

you will need a longer thread that is..

Tks

jacko - 31/12/07 at 04:13 PM

Hi have a look in my photo archives under engine stabiliser bkt

it may help you

Jacko

just cut the face of the box so you can grt to the nut

[Edited on 31/12/07 by jacko]

keith2lp - 31/12/07 at 07:20 PM

Tack weld the nut to the plate then you don't need to have access to the nut as you can screw the mouting rubber on.

I have used this method on both a pinto & duratec engines and is used by many kit manufacturers.

davidosullivan - 1/1/08 at 09:56 PM

Thanks guys, I decided just to weld it in.

Thanks,

David