I am using Fiesta rubber mounts which are 43mm high, does anyone know of any suitable rubber mounts a little taller?

Thanks

Rescued attachment Engin angle.jpg

Right, after installing my engine it's sitting at a bit of an angle (nose pointing down). I've been told this is how they are fitted to Catteringvans,

and a little angle was required to get it under the bonnet! BUT I appear to have overdone it (cocked it right up!). Will this have any detrimental

effects on my engine?

I am using Fiesta rubber mounts which are 43mm high, does anyone know of any suitable rubber mounts a little taller?

Thanks

Rescued attachment Engin angle.jpg

I would have thought that the engine should sit level????

IMO it looks too low at the front, but that is just gut feel.

You'll have no trouble with oil accumulation in the Vauxhall head, that'll drain back OK so no problem there.

Cooling system will be unaffected at that angle.

What sump are you using? You should still be OK but check that sump/pick up pipe location is OK and at deepest part of sump and preferably at rear of

engine. Make sure angle is OK to drain oil back from front to rear of sump when car is on level ground.

Only other consideration is fuelling. If you are using some sort of downdraft carb there may be a float/fuel level problem, but that would be overcome

by machining carb to manifold face to get it back horizontal. Sidedrafts should work OK at the angle you have although from a cosmetic point of view

the engine angle would be noticeable when viewing your shiny K&N filter covers from the side!

Yeah,

But I've been told that the Cateringvan sump is shallower at the front than the back because the engine is lower at the front than the back

Will anything nasty happen to my engine?

Thanks

I've hopefully got a nice second hand Cateringvan ali sump sorted. The guys just working out the postage.

What engine mount rubbers do others use? And could someone measure them for me please?

Thanks for the replies fellas.

Chris can't edit previous post

Forgot to say I'm keeping in on Injection and making my own inlet manifold

Thanks

I'm not familiar with the sumps that C*** fit to their 1600 Vauxhalls, but am with their X'Flows.

Are you using one of their sumps?

If you are going to make your own, ensure that the front is higher than the rear, that the pick-up pipe is in the deepest part at the rear, that it

goes to within half an inch of the bottom of the sump, and there is a degree of baffling within the sump and especially around the pick up pipe

strainer.

Just seen a Zetec caterham on telly and the engine sits level..

I would have thought the engine and box would not complain, but the prob might spit out bits of roller bearings in protest

could you not make up new engine mount brackets from the engine to the top of the mounting rubbers......I did. Had to cos the alu ones on a cologne

were too wide and cant be cut down.

Alternatively, could you not make some kinda raised platform / column to take the rubbers so that they sit higher, and therefore push the engine up

level?

I jacked my engine from the sump so it was level, and built the mounts from there.

atb

steve

Sump: Yes Cateringvan, I will post some pictures. It is higher at the front than rear (if the engine angle is right!) and uses a foam baffle to stop

oil surge.

Mounts: I did make them! It took me nearly all day Sunday. I must have either cocked up a little or the rubbers have compressed more than expected. I

really don't want to make any more hence why I asked the hight of other engine rubber mounts. The ones I'm using are 43mm, anyone know any a "bit"

taller?

Thanks

Rescued attachment 11100208.jpg

Here's another one:

Rescued attachment 11100210.jpg

ohhh

i need that sump and im gonna tilt my engine at that sort of angle to fit under a lowish bonnet line.

im using a 20xe and a sort of avon front end

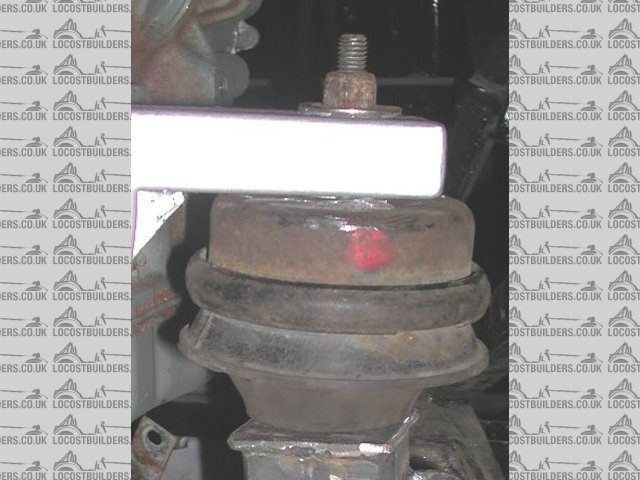

the ones from a 1987 ford v6 cologne granada are 'about' 70mm tall and have a 10mm stud approx 35 - 40mm long each side.

I say approx cos they are not easy to measure and its as accurate a mark as my thumb can make on a tape!

see piccy for appearance:

Rescued attachment mount.jpg

Hi Northy, just remember the output of gearbox drive yoke should be in parallel with the input drive flange on the differential, or you can develope

some sereious vibrations. cheers davef.

Agreed.. mega important that both knuckles on prop are parallel with each other.

offset.. but parallel.

Why does it thave to be parallel? If it was a live axle it would be moving up and down a bit.

Is it parallel on a production car?

Thanks

uj on prop shaft are not constant velocity joints.

If you dont have the flanges parallel then you get accelleration and decelleration in the joint angles as it goes through 360 degress and this shags

them rapidly - so im told

However, I am not aware that its obligatory to have a slight front to back angle to the prop as has been said elsewhere....

atb

steve

Yeah I can understand why the flanges need to be parallel, but wouldn't some front to back angle also wear the joints?

Confused