ST170 Supercharger project

richardm6994 - 2/6/17 at 07:25 PM

As a bit of inspiration to anyone contemplating a supercharger project, I'd just thought I'd share some photo's from my latest project

- Eaton MP62 Supercharger on a ST170 engine inside a GBS Zero;

Close up of alternator bracket;

Charger mocked up in the engine bay

GTIR Plenum back plate being machined

Finished GTIR Plenum back plate

Supercharger Outlet plenum being machined

Finished Supercharger outlet plenum

Freshly rebuilt supercharger c/w precharger throttle body and BMW bypass valve

Supercharger crammed into the engine bay

Jenveys refitted (very tight)

Intake plenum fitted and boost pipes connected

Almost fits under the bonnet

And finally a little video showing 10psi of boost, although in desperate need of a rolling road....

https://www.youtube.com/watch?v=psF5AD8G8Vw

bi22le - 2/6/17 at 10:38 PM

Nice build, something I am still hoping to do.

Questions:

So you have a pre SC butterfly and Jenvey TBs, are these both cable operated and off of the same cable?

Are you limiting the SC to 10psi with pulley ratios ordoes it naturally make that and no more?

Are you only running a rerecirc and no blow off valve?

Do you have the SC clutch fitted and do you activate it at any time?

What is the expected hike in power?

big_wasa - 3/6/17 at 08:26 AM

I love your work on the mill.

richardm6994 - 3/6/17 at 09:15 AM

Thanks,

The precharger TB and the jenveys each have their own throttle cable going back to the pedal. You can't allow the precharger tb to close fully,

it needs about 3or4mm of opening when closed.

from memory, the zetec crank pulley is 126mm dia. Using a 65mm charger pulley on the last 2 project gives peak boost between 10 and 11 psi.

I have also experimented a 55mm supercharger pulley, and this saw 12-13psi. This really is the smallest you can go because any smaller you can't

stop the belt from slipping. Also, zetecs are good for up to 11psi in standard internals so unless you've uprated the insides, you wouldn't

want any more than 10-11psi.

Only running the BMW mini bypass valve. This is a must as without it, the noise is horrendous at closed throttle.

Never used the supercharger clutches. The main reason is the standard clutch pulley is 100mm dia and realistically, I think it could only be reduced

to 80(ish) and so the charger pulley ratios wouldn't be great (a lot of work for 5 or 6 psi)

On a 2ltr engine, the chargers I've done have added 60-80 bhp, however it's the torque figures which really impress. The owner of the last

charger I did described the engine characteristics as a cross between a v8 and straight 4.

Im always happy to help anyone with their projects be it guidance or full on machining. All the best

richardm6994 - 3/6/17 at 09:33 AM

This is the rolling road graph from the last supercharger project - 10.5psi, 245bhp and 213ftlbs from a fairly standard silver top engine.

bi22le - 3/6/17 at 08:07 PM

Thanks for the info.

Hopefully Ill crack on with mine one day.

ChrisL - 17/1/18 at 10:31 AM

Hi Richard,

Thanks for the pic's and write up. I am doing a similar thing, M62 on a Blacktop 2 ltr Zetec and you've given me some good info.

Would be interested to know if you'd be interested in making me an alternator and supercharger mounting brackets?

Thanks

Chris

ChrisL - 23/2/18 at 10:10 AM

One question, have you used a decompression plate?

Cheers

Chris

richardm6994 - 23/2/18 at 10:29 AM

No need for decompression plate on zetecs with low boost.

Iíve heard 14psi is safe on standard internals and compression for zetecs but not gone this high myself, my chargers only go up to 12psi and all have

been fine on standard internals and compression.

richardm6994 - 23/2/18 at 10:38 AM

Here is the dyno which it gave 267wbhp

https://youtu.be/RwiAMIH7RDw

Simon - 23/2/18 at 08:09 PM

Nice

ChrisL - 24/2/18 at 09:25 PM

Thanks Richard, aiming for the same PSI so should be good.

ChrisL - 4/3/18 at 04:56 PM

So this is the plan for the pulley, bore the centre out so it will sit over the nose bearing:

Bearing:

Description

Pulley

Description

Then trip the top hat down and put some bolts through into the bored and tapped pulley.

Top hat:

Description

So anyone got a lathe in the north herts/beds area?

Cheers

Chris

richardm6994 - 4/3/18 at 05:15 PM

Thatís exactly what Iíve done on my charger projects.

Just a word of advice when machining the pulley:- donít use a 3jaw chuck as it wont be accurate enough. 4jaw chuck and plenty of patience with a dti

is essential.

ChrisL - 6/3/18 at 06:21 PM

Thanks for the advice.

ChrisL - 24/4/19 at 09:53 AM

Another question from me, what injectors are you running, I'm thinking 440cc....

theduck - 24/4/19 at 11:59 AM

440cc are safe to about 275bhp in supercharged 4cylinder applications, though you can squeeze a bit more from them if needed.

ChrisL - 24/4/19 at 01:36 PM

good to know, I guess I'm looking at a couple of hundred for some bosch one then..

theduck - 24/4/19 at 02:28 PM

Impreza "baby blue" are a nice option for 440cc, used at around £40-50 Can also get impreza "pinks" and "dark blue"

which are 540-550cc for around £100.

ChrisL - 7/5/19 at 08:25 AM

Getting close to first attempt at starting, just need to fit 2 more fuel lines, an alternator belt and the last bit of the air way. I would put up a

picture but seem to be having technical issues. One more question I have, bearing in mind my build is on a 2 ltr black top Zetec, should I fit ARP

conrod bolts?

theduck - 7/5/19 at 08:57 AM

Not sure how required they are, but I know a couple of guys who have done budget turbo builds and they both fitted them.

big_wasa - 7/5/19 at 06:27 PM

Iíve fitted Arpís to mine as a little extra insurance.

Also running mk1 Rs 440cc injectors as there not to dear new.

Re photos, itís a case of re sizing them ( as this site doesnít ) and hosting them on a third party site. Imgur seems ok while it lasts.

[Edited on 7/5/19 by big_wasa]

ChrisL - 7/5/19 at 07:07 PM

ARPs it is then, which is a pain as I've just put fresh oil in!!

I've gone for the Bosch greens which are in.

Re the photos, I've tried resizing down to the same size as other images I've uploaded but am still getting SQL errors. I'm sure

it'll get fixed at some point.

Currently looking at clutch options, I think I need a 23 spline (type 9) and 220mm Zetec silver top 1.8 fly wheel.

furryeggs - 7/5/19 at 07:31 PM

How/where is the SC bolted to the side of the block?

big_wasa - 7/5/19 at 07:35 PM

Re photos, the forum is broken you have to host them on a third party site.

Re the clutch, Depending on the spec of your engine/clutch you may struggle with it holding the torque of a blown engine. Iíve gone for a 240mm Rs

spec steel flywheel and Focus Rs clutch.

ChrisL - 7/5/19 at 07:37 PM

It's bolted just above the oil filter at an angle. Space is v very tight. I've followed Red7/richardm6994 has done.

Re Clutch, I'm so close to starting it up that I don't really want to take the engine out, but if it does start slipping I guess I'll

have to. i think when I do I'll be able to get the measurements of the existing clutch paste and see if Burton Power can match it to something g

beefier

[Edited on 7/5/19 by ChrisL]

big_wasa - 7/5/19 at 07:58 PM

I would speak to some one like helix as you will need a cover plate with more clamping force. There isn't a lot of off the shelf choice at

220mm

See how you get on. The power delivery of the charger will be different to my turbo

Save the Arp's until the engine comes out

ChrisL - 8/5/19 at 05:40 AM

Fingers crossed, only 7 weeks until I'm supposed to be doing a Euro tour

[Edited on 8/5/19 by ChrisL]

ChrisL - 2/10/19 at 02:02 PM

I seem to be posting on multiple threads, however I though I'd update this one, I have made progress, still need to sort the tune out but it

looks like I'm making about 11psi of boost.

Anyone got a megasquirt map I can have a look at to get an idea of sensible ignition timing on boost?

ChrisL - 23/4/20 at 09:23 AM

Another update, as posted on one of my many posts, I've mashed the pistons,

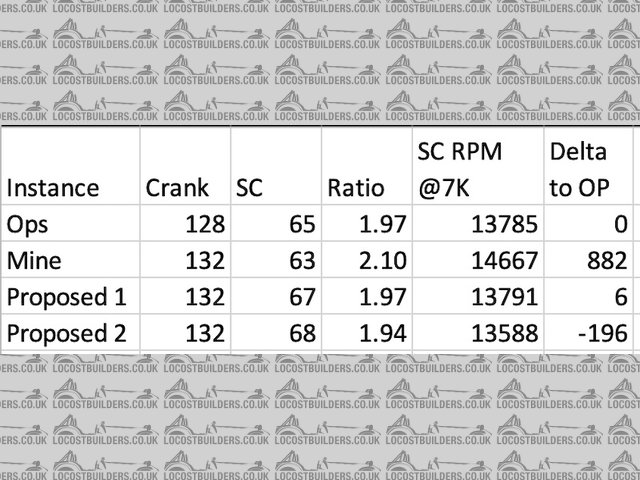

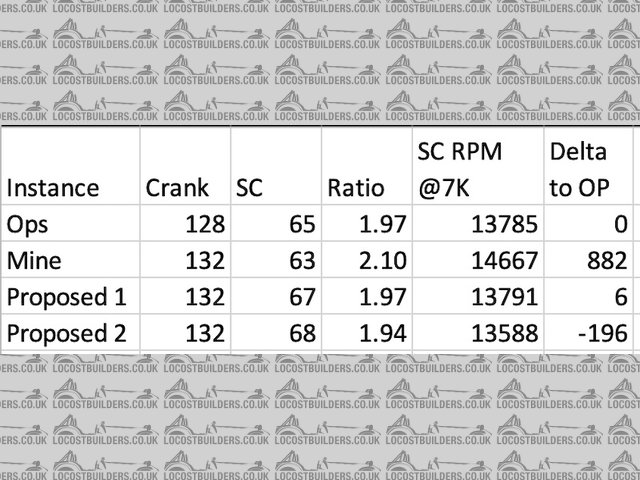

Based on the OPs specs it seems that my crank pulley is bigger and the 65mm SC pulley turns out to only be 63mm not 65mm!

The OP/Richard used the following (you'll need to view the pic)

Description

Now given that I'm using a charger cooler so should get lower intake temps than Richard should I play safe and go for a 68mm SC pulley or play

even safer and go for an even bigger pulley?

Also any recommendation on who to get the pulley made up by?

TIA

Chris

Pic's of the pistons:

Description

Description