Or maybe I'm wrong, some people on here are pretty encyclopaedic!

Just trying to ensure you get what you want!

James

Evening all,

I've enjoyed reading about others experiences and projects and would like to delve into the think tank.

I'm having some musings at the moment and was wondering if anyone had an idea of any 4-pots that have a cylinder centre spacing of 66.67mm or

2.625" (likely to be a 500-750cc bike engine?!). Specific I know but I have a reason.

Thanks in advance.

Cheers,

David

Probably worth saying what block you would like to fit it to. Not wanting to denegrate the knowledge of my fellow LB members but I can see people are

more likely to remember having randomly read on some forum that head X fits block Y than they are to remember that head X has a certain centre

spacing!

Or maybe I'm wrong, some people on here are pretty encyclopaedic!

Just trying to ensure you get what you want!

James

IIRC someone fitted a BMW K75 bike cylinder head (Brick) to a BMC A series (old school Mini) engine if that helps as a starting point?

Cheers, Pewe10

BMW K1200 head is another popular choice!

Linky

Thanks for the reply folks;

I have read a bit on the mww/a-series conversions, unfortunately the bore spacing is too big!!

As I said these are just musings at the moment... the idea would be to build an Austin Seven Special

and try and convert it to a twin-cam head. OHV conversions were available waay back in the day

so i reckon an dohc can be done; for no other reason other than it doesn't appear to have been done

before.

I have been able to find bore spacing (i.e. centre of one cylinder bore to the middle of the next one.),

as mentioned in initial post, of 66/67mm personal research hasn't revealed anything but I was hoping

someone on hear may have a beeter knowledge and would be willing to share.

Please remember that this is just ideas floating in my head (not much for it to bump into either ) and

) and

it'd be a good few years before I had time, space and money to start it.

Skill...I'll probably never have but I think this would be a great project to learn with!!

Thanks again for your time.

Cheers,

David

An old three bearing crank with a 16v head on top would not be very good friends.

Cheers,

Nev.

quote:

Originally posted by Neville Jones

An old three bearing crank with a 16v head on top would not be very good friends.

Cheers,

Nev.

Dont use a 3 bearing engine Austin Seven engine, they were only produced for a short time and are well known for centtre bearing problems. Some of

the 50's special racers got it to work but most stuck to the 2 bearing.

The better engine to use is the 2 bearing engine, despite the fact that the crank "whips"

A company called Pheonix crankshafts have now produced thousands of 2 bearing cranks for Austin Seven engines

that have practically solved the traditional handicap of cranks breaking at the rear journal. You can also go to pressure feed instead of spit and

hope lubrication.

To allow for the whip it is customary to machine 20 thou off the pistons of 2 and 3 to stop them touching the side

valve head at high revs, so not sure how your OHV conversion is going to cope with this as your valves will be facing the pistons not sitting next to

them?

The works racing versions had special blocks cast that had more holding down studs on the base and

also many more studs holding the heads on.

And I presume that you are aware that Austin produced a twin cam racer thereselves pre war?

Good luck , sounds interesting and if you are serious go look at the austinsevenfriends forum and ask questions.

Steve

quote:

Originally posted by Neville Jones

An old three bearing crank with a 16v head on top would not be very good friends.

Cheers,

Nev.

quote:

Originally posted by Cornishman

Dont use a 3 bearing engine Austin Seven engine, they were only produced for a short time and are well known for centtre bearing problems. Some of the 50's special racers got it to work but most stuck to the 2 bearing.

The better engine to use is the 2 bearing engine, despite the fact that the crank "whips"

A company called Pheonix crankshafts have now produced thousands of 2 bearing cranks for Austin Seven engines

that have practically solved the traditional handicap of cranks breaking at the rear journal. You can also go to pressure feed instead of spit and hope lubrication.

To allow for the whip it is customary to machine 20 thou off the pistons of 2 and 3 to stop them touching the side

valve head at high revs, so not sure how your OHV conversion is going to cope with this as your valves will be facing the pistons not sitting next to them?

The works racing versions had special blocks cast that had more holding down studs on the base and

also many more studs holding the heads on.

And I presume that you are aware that Austin produced a twin cam racer thereselves pre war?

Good luck , sounds interesting and if you are serious go look at the austinsevenfriends forum and ask questions.

Steve

quote:

Originally posted by worthidlj

Hi Steve,

Below is a link to a patented OHV conversion, I have also been on the austinsevenfriends forums often reading up on things and posting a couple of queries too. One reason I posted this in here is if I tried posting there I may get lynched!!

[HTML]http://bruce-white.austinharris.co.uk/Overhead_Valve_Conversion.htm[HTML]

Interesting reading!

By some unknown coincidence I was looking at some car parts on ebay just now and this appeared as one of the listings advertised on the bottom:

Austin 7 Seven Phoenix crankshaft | eBay

Not sure if it's relevant, but seems a lot for a Austni 7 crank!

Why only upgrade half the engine? Do the job properly and make your life easy by changing the whole thing!

Cheers,

James

quote:

Originally posted by James

Why only upgrade half the engine? Do the job properly and make your life easy by changing the whole thing!

Cheers,

James

I think we are talking about the pre war Austin Seven engine not the later A series!

The pheonix crank in 1"5/16" non pressure feed is about £750 new plus the same for their rods.

The pressure fed versions and the larger 1"1/2" sizes are priced differently.

You would be suprised about the friends forum, yes they have some rivet counters on there but

there are also some very skilled engineeers on there who are interested in modifications.

I think Pigsty racing are getting 50 plus BHP out of their 750cc sidevalves, which in a special weighing

about 250-300Kg is enough to have fun given the limitations of cable brakes!!!

Before building up this hillclimb Locost I was seriously looking at building another Austin Seven special

as a smaller scale copy of the Locost design and using a Reliant OHV engine that I just happen to have here.

I'd be very interested in your progress if you make any

Steve

We all love a good engineering project - as you say, it's as much about the journey as the destination.

We're not building kit cars cause it makes sense, we do it cause we enjoy it!

Whatever you decide to do, definitely start a build thread on here - I'll be following with interest.

Thanks for the comments guys,

I know there are likely to be those who would appose this on ASF (Austin Seven Friends) and who would support it but I jusy feel that this forum would

give me a bit more insight on bike heads and dimensions, especially those with BEC's.

I've heard about the Reliant OHV being used in Seven Specials but can't find much on the net of people who have done it.

I wouldn't hold your breath though as it would be a few years before I get close to een thinking about starting it. Work and Open University see

to that.

If/when I do start I'll be sure to keep posted.

Cheers,

David

[Edited on 21/1/12 by worthidlj]

quote:

Originally posted by James

Why only upgrade half the engine? Do the job properly and make your life easy by changing the whole thing!

Cheers,

James

Good afternoon guys,

After a few days searching I have found a few bike 4-bangers with areasonable bore size; either original size or ones that can be used in a bored out

block:

- Kawasaki ZXR400 - 57mm bore.

- Kawasaki GPZ550 - 58mm bore.

- Yamaha FZR400 - 56mm bore

- Yamaha XJ550 - 57mm bore.

Unfortunately I cannot find any info online aboutthe bore spacing for these bikes so was wondering if anyone on here knew or know someone that did?

Thanksin advance.

Cheers,

David

There's an engineering company in Fleet called Roe Engineering who specialise in engine overhauls.

He's pretty knowledgeable about a huge range of engines so might be able to offer advice.

HTH.

Cheers, Pewe10

[Edited on 24/1/12 by pewe]

If you google for head gaskets of these then you should be able to get some approximate dimensions.

Minor update...

Finding parts lists with exploded diagramsof these bikes show that cylinder head design of thee mean that cylinders 2 and 3 are too far spaced apart

so the only option left is the Kawasaki ZXR400.

Internet trawlinghas returned no results with regards to it'sbore spacing.

The best I have been able to do is get a picture of a head gasket; blow it up to A4 measure the bore size and wall thickness of the picture (52 and

9mm respectively) and knowing the actual bore size (57mm) I have calculated actual wall thickness being 9.8653846153mm, therefore giving a calculated

bore spacing of 66.8653846153mm.

Now scaling of the photo and printer are likely to have skewed the measurements but with the Austin engine having a bore spacing of 2.625" aka

66.675mm gives mehope that with a bit of recessing around the top of the bores gives the faint whiff of hope!!

The challenge now would be to get a block and gasket together (unless someone could confirm the ZXR400's bore spacing - I've sent a few

emails and awaiting replies) and see how everything lines up!!

One last thing though: do both engines turn the same way? If not I would have to look into getting custom cams made to allow the cams to work in the

new layout which also has the advantage of being a crossflow design keeping the exhaust on the normal side making fabrication easire to deal with!!

Thanks for the interest.

Cheers,

David

My old boss is an Austin nut and runs a Speedy (Austin 7 based factory special) which he's rebuilt a number of times. The Achilles heal of the

whole car seems to be the engine. Bearing in mind he has to keep everything original down to the felt oil seals to preserve the originality and value

of a fairly rare car. He's had various engines built and rebuilt right up to a newly cast block and billet crank (all made to OE spec) and

they're just not reliable.

Obviously you're machine wouldn't be standard with a 16v head which makes me think it would be much more effective to select a suitable

complete engine and fit that - it would have to be something small though - Coventry Climax or maybe a sub 1,000cc bike motor...?

quote:

Originally posted by nick205

My old boss is an Austin nut and runs a Speedy (Austin 7 based factory special) which he's rebuilt a number of times. The Achilles heal of the whole car seems to be the engine. Bearing in mind he has to keep everything original down to the felt oil seals to preserve the originality and value of a fairly rare car. He's had various engines built and rebuilt right up to a newly cast block and billet crank (all made to OE spec) and they're just not reliable.

Obviously you're machine wouldn't be standard with a 16v head which makes me think it would be much more effective to select a suitable complete engine and fit that - it would have to be something small though - Coventry Climax or maybe a sub 1,000cc bike motor...?

quote:

Originally posted by worthidlj

quote:

Originally posted by nick205

My old boss is an Austin nut and runs a Speedy (Austin 7 based factory special) which he's rebuilt a number of times. The Achilles heal of the whole car seems to be the engine. Bearing in mind he has to keep everything original down to the felt oil seals to preserve the originality and value of a fairly rare car. He's had various engines built and rebuilt right up to a newly cast block and billet crank (all made to OE spec) and they're just not reliable.

Obviously you're machine wouldn't be standard with a 16v head which makes me think it would be much more effective to select a suitable complete engine and fit that - it would have to be something small though - Coventry Climax or maybe a sub 1,000cc bike motor...?

The engine swap had crossed my mind but I just want to do this for myself;with it being based on using a Special so originality/rarity is less of an issue. Plus keeping core components standard, or modified versions of standard parts, it would allow me to circumvent the IVA test and make it easier to return to original specs.

Remember this is all a pipe dream at the moment and am just checking feasability for a, hopefully, few years time.

Cheers,

David

Minor muse and thought update.

Good thing is the ZXR400 rotates in the same direction as the Austin 7 motor and pistons and crank are the same layout.

Firing order is different though (A7: 1-3-4-2 plays ZXR: 1-2-4-3) but as I would be using the fueling and ignition from the ZXR it shouldn't

casuse any issues.

The issue now would be driving the cams...main issue being that the A7 is gear driven and ZXR is chain driven, also with the design of the A7 engine

the cam gears on the ZXR head would sit behind the gear on the crankshaft.

Sooooooo, how to overcome this conumdrum (especially theoretically as I actually don't physically have any of the parts  ); one thought I had

was to in keep with the original design and build a gear-drive mechanism, either using extra A7 crank and cam gears or custom ones with a fabricated

mount from A7 cam gear to ZXR cam gears.

); one thought I had

was to in keep with the original design and build a gear-drive mechanism, either using extra A7 crank and cam gears or custom ones with a fabricated

mount from A7 cam gear to ZXR cam gears.

I'm trying to get hold of dimensions for a mock-up to see how it could be done.

Bit of a waffle but kind of where I'm up to at the mo... if it seems feasable enough and may even try to do it for my note Open Uni module!!

Any advice/opinions always welcome.

Cheers,

David

whole zxr400 engine on that auction site presently at £102.

Sounds like you have done enough theory to have a punt.

Your plan-B could be to put the whole engine in!

quote:

Originally posted by matt_gsxr

whole zxr400 engine on that auction site presently at £102.

Sounds like you have done enough theory to have a punt.

Your plan-B could be to put the whole engine in!

), scouts, swim coaching and

still living at home with the parents mean this is just theory at the moment and are just plans for a couple of years time at the moment.

), scouts, swim coaching and

still living at home with the parents mean this is just theory at the moment and are just plans for a couple of years time at the moment. Thread bump again!!

Uni work has restricted any reasonable research, but searching on ebay has found a supplier (cradleykawasaki - no affiliation!) who was kind enough to

give me a couple of dimensions.

Turns out the bore spacing is approx 67.5mm; now the bore spacing for an Austin Seven engine is 2.625inch, converting this to mm means there's a

difference is approx 0.83mm.

Does this seem too much of a difference or do you reckon I could get away with a bit of machining to allow the valves to movw without hitting the

bores?

Further inspiration comes from a PPC article where somone fitted a zetec head onto an MGB B-Series block, even though the cylindes are siamesed, so

maybe some hope!! :-)

If i am reading this right, you want a lot more power out of an austin 7 engine?

If i am reading it all correct, !!

have you ever driven an Austin 7 on the road ? as i have, and more power out of the engine is not required,

brakes that work is a MUST first

The old Austin 7, and the like were never designed for the modern world, and the brakes were never designed to actually work

quote:

Originally posted by steve m

If i am reading this right, you want a lot more power out of an austin 7 engine?

If i am reading it all correct, !!

have you ever driven an Austin 7 on the road ? as i have, and more power out of the engine is not required,

brakes that work is a MUST first

The old Austin 7, and the like were never designed for the modern world, and the brakes were never designed to actually work

). This is more just initial musings

). This is more just initial musings

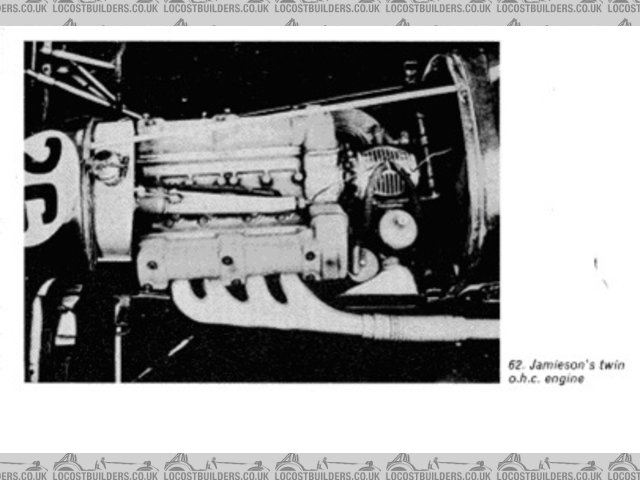

[img]

Description

[/img]

If this works here is a poor picture of a twincam supercharged Austin 7 engine just as a thought.

Austin 1

Interesting thread this, many years ago I half built an A7 special and got it to a running stage, see above, this was when I discovered that firstly

the clutch is a switch just in or out. Fortunately the engine didnít seem to have any power or torque band it just ran at different speeds so the car

would just jump forwards. The brakes were hopeless even when only fitted with a bit of wood and aluminium as a body so anyone driving one on the road

with standard brakes must be very brave. The design of the front braking is not good, the cables pull the brakes on, as the brakes start to work the

reaction from the hub twists the axle rearwards, releasing the force applied by the cable, so it is a sort of self regulating system, ensuring the

brakes canít work very well.

Regarding the crank failures, the engines were bolted down to the A frame chassis by 4 bolts through lugs on the engine a sort of extended sump

flange, when the chassis twisted it twisted the block which helped the crank to snap, Colin Chapman discovered with his racers that if you only used 2

bolts crank life expectancy was much improved.

ok not written in a while but enjoying reading other peoples projects.

I've potentially located a cylinder head and keeping an eye on a block too.

Though bore centres are very similar I am slightly concerned of valves hitting the bores.

Would it be possible to grind small recesses into the tops of the bores to allow the standard

valves to be used, and if so what tools would you recommend to do this kind of work?

Cheers,

David

Yes you can 'pocket' the edges of the bores but you'd be chipping into the area where you don't want to! You'll end up creating hot-spots and encroaching on the fire ring. You would be better using smaller headed valves, with undersized seats, lifting the seat faces up into the head and using dome-topped pistons or (my preferred method!) machining a new head from billet alloy!

Thanks for the reply, I'm hoping I wouldn't have to but would just like to try and cover any eventualities.

If I did have to pocket the bores what tools would you recommend for a DIY-er?

Cheers,

David

P.S. Owelly, I enjoy reading your exploits in the PPC mag

This:

quote:

Originally posted by worthidlj

Firing order is different though (A7: 1-3-4-2 plays ZXR: 1-2-4-3)

quote:

Originally posted by sebastiaan

This:

quote:

Originally posted by worthidlj

Firing order is different though (A7: 1-3-4-2 plays ZXR: 1-2-4-3)

Is a deal-breaker. Or at the least will require different cams for the head. 1342 and 1234 would be interchangable using the same crank, but 1342 and 1243 won't be. Think about it ;-)

Full point for the idea though, and getting custom cams made up should be possible, though expensive.

1-3-4-2 and 1-2-4-3 are surely interchangeable? 1 and 4 are up together and 2 and 3 are up together. Reversing the firing order within either or both pairs would be okay, you just can't change between pairs.

This will maybe help with your research. Check out the Turner twin cam head designed by Jack turner. He designed this for his 500cc racing engine but it was fitted to an A series engine for development. The 500 engine complete with the twin cam head can be seen in the Coventry Motor Museum. Might give you a few ideas.