Straigth swap for a silvertop or blacktop.

Found an ST170 for a decent-ish price (400 quid?). From what I understand these "Duratecs" are actually a Zetec engine with VVTI so will fit

my MT75 rwd box. The engine is missing an inlet and some ancilliaries so:

1) What is the main difference between a ST170 and a standard black-top?

2) Is the inlet interchangeable?

3) Does the ST170 need a different wiring loom/ECU? (May be a moot point as I've got a megasquirt lying around)

4) Has anyone run the ST170 in a kit with the VVTi or have people somehow locked it out/got rid of it? If so, how?

Thanks,

Pavel

manifolds will swap over but the ports are a little higher so not a perfect match with out porting.

quote:

Originally posted by PSpirine

Found an ST170 for a decent-ish price (400 quid?). From what I understand these "Duratecs" are actually a Zetec engine with VVTI so will fit my MT75 rwd box. The engine is missing an inlet and some ancilliaries so:

1) What is the main difference between a ST170 and a standard black-top?

2) Is the inlet interchangeable?

3) Does the ST170 need a different wiring loom/ECU? (May be a moot point as I've got a megasquirt lying around)

4) Has anyone run the ST170 in a kit with the VVTi or have people somehow locked it out/got rid of it? If so, how?

Thanks,

Pavel

http://passionford.com/forum/technical-help-q-and-a/383466-aftermarket-ecu-for-st170.html

I run an st170 engine on megasquirt.

The vct is a waste of time, time up the inlet cam for full lift at 110 degrees for peak power.

All the wiring is the same as a normal zetec, and there is loads of power to be had from it

Thanks both.

Reading the other forum it seems possible to get the MS to activate the VVTI as on/off (much like a VTEC).

Perhaps with a switch on the dash it could be made to have a "cruising" mode when VVTI activation would work.

Are the standard Ford ECU's untunable then?

Thanks,

P

Having run the vvt take my advise and ditch it.

You can run it with a standard ford deep/desk/dewy ecu with matching maf sensor will with good results. A friends st170 engine made 155bhp with that

setup.

If your running an aftermarket setup with a switch for it, you will find the car running dangerously lean when you activate it. Fixed cam timing and a

proper map will give you a good powerful engine!

I have a St170 in mine, when I put it in I used the inlet and exhaust sraight off my silvertop, all worked well and the only other ting was the VVT,

triggered it off the megajolt with a relay

Straigth swap for a silvertop or blacktop.

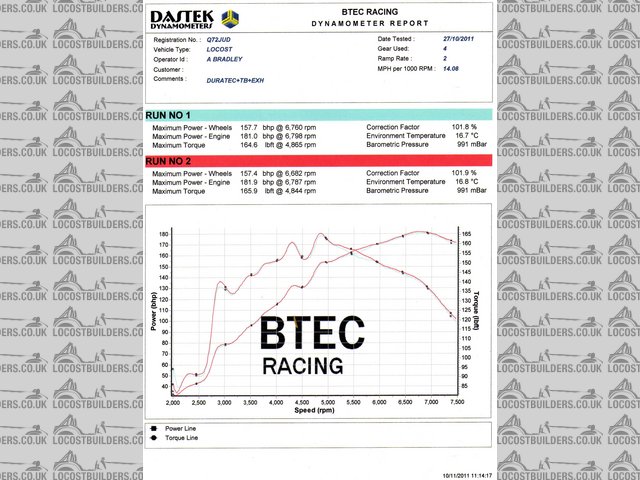

I run a ST170 in my locost,

The VVC is well worth trying to get mapped, I used the ST inlet with GSXR bodies and a old Omex 500 ECU, this is controls the VVC the same as a

megasquirt by using the shift light output.

Power is roughly the same, but with a 15 FtLbs increase in torque, check out the difference in Torque curves below.

rolling road 05/08/10

VVc

ATB Dan.

Running vvt leaves the cam at 90degrees at rest, and 130 degrees at advance, neither of these are the cams peak power figure. I understand the reasons for running it, and I did previously, however there is a better way of doing it.

The ST's VVT need to be correctly controlled or it may as well be just locked off in one position.

The VVT is full variable and i have seen some good results on a standard ST170 engine/inlet with the correct mapped vvt putting out 193bhp. When it

would only do 163bhp with the vvt not correctly working.

quote:

Originally posted by Rob Allison

The ST's VVT need to be correctly controlled or it may as well be just locked off in one position.

The VVT is full variable and i have seen some good results on a standard ST170 engine/inlet with the correct mapped vvt putting out 193bhp. When it would only do 163bhp with the vvt not correctly working.

The VVT is not just on or off. It is a variable system. I dont have the full information on the timing at the moment but its something like this.

The inlet timing varies by 60deg from 85deg btdc to 145deg btdc. Its not just on or off. So if you use it just switched the timing will go from 85deg

btdc to the full maximum of 145deg btdc. The maximum power is not developed at either of these settings.

So far it looks like 142deg btdc is giving the best power figures on a standard manifold set on the long inlet runners. its not been dynoed with

throttle bodies yet.

The VVT is a PMW system so it a 1 to 5 volt pulse that increases in frequency. This opens and closes the vvt solenoid to variy the oil pressure to the

cam vvt. Just putting a 5 volt signal on to the solenoid will force the cam timing to the max setting of 145deg btdc.

The problem is finding an ecu that will control the VVT with PMW control. If your just going to use a switched 5 volt to the vvt then you may as well

just fix the vvt in one position using a vvt delete kit, as you will get better power setting the timing to a better position i.e, 140deg btdc area.

Rob are you sure it is 5V that triggers the solenoid. I have been told by DTA that the solenoid is 12V operated.... but this is not the first time I

have heard it is 5V... Mine is wired to 12V but not sure if it is working correctly....

Dave B.

Thats one of the things i'm unsure about. Still trying to get the information on the driver signal and timing info.

The idea of the vvt is to advance and retard from the normal timing position.

Under high load, high rpm the timing is retarded.

Under Low to medium rpm, high load the timing is advanced.

Under light engine load the timing is retarded.

And its not just a case of on or off. Its variable amounts of degrees. Thats why in most cases the engines are only showing 150 to 170 bhp. If the VVT

cant be used right then it should be just locked off, as it will make far better power.

I know someone with one on carbs, fixed cams and a little head work thats about 220bhp. It needs to rev though 8500rpm

I have been trying to get good info on the Ford VCT for some time. I think Rob's summary is basicaly correct as far as power and torque are

concerned but we must remember that VCT ( not to be confused with Honda V-tec which is completely different in both intent and function ) is as much

an emissions and fuel economy optimisation device as any thing else and this is why the required map is so complex in the standard Ford ECU. If we

only require best power and torque I believe things can be made easier.

A couple of years ago one of the kit car mags , I forget which, built a Riot with 1.7 Puma engine. This was fitted with an Omex 600 and mapped by

Omex. As I recall they took basically 2 power curves 1) at full advance and 2) at full retard. Max power ( equal to standard catalogue spec ) was

achieved at full retard but torque was improved by up to 20% between 1500 and 6000 rpm with full advance. Hence I believe simple switching at

appropriate speeds, while perhaps not quite optimum, is a pretty good aproximation for our purposes.

As another check on this is if you look at the Piper cam catalogue you will see that static timing for eqivalent 1.6 ( non VCT ) and 1.7 ( VCT ) cams

( for the Ford Sigma engine ) is basically the same, indicating that full retard of the VCT is best for power.

When I get the chance I intend to put a volt meter on the VCT selonoid and get a WOT curve done. This should show what the Ford standard ECU does

under these simplified conditions. Could be done with a standard Puma if I had one!

Load of bollocks, mine would not trigger at 9v never mnd 5v. Check the Focus wiring diagram, it sits on a 20 amp fuse with 1mm wiring. It takes 12v to

trigger and its not worth PWM it on our cars.

AND, if I'm wrong tell me what the best position is to lock the cam at. However I am more than happy with the sudden 100hp increase in power when

it kicks in....

Also no good comparing with the Puma, its totally different system. Puma is electronically controlled whereas the ST170 is mechanical....

Mine is setup as advised by Northamton Motorsport and it comes on at 1500rpm and above 30% TPS. This means its variable in that at WOT its at maximun

and off on the overun.. oil pressure deals with the rest.

Theres no advantage in trying make it more complicated!

[Edited on 18/2/12 by coozer]

Very interesting, I did not know the ST 170 system was different to the Puma, but since a Puma is what I have got it is what I need to understand in more detail. Sadly I have not found any published information that is any use. Sorry if my post caused any confusion, obviously the wrong thread.

I know someone that is doing his Motorsport degree on an ST170 supercharged engine. So I should have the info on the vvt/timing/power soon

Hi was any further information found on the above, i've very keen to know as i have bought Coozer old MNR and i'm planning to taking it for mapping and need to know if i should just invest in a cam locking kit or carry on using the omex 600 ecu to control the vvt to fully advanced over 2000rpm/20% throttle

quote:

Originally posted by coozer

Load of bollocks, mine would not trigger at 9v never mnd 5v. Check the Focus wiring diagram, it sits on a 20 amp fuse with 1mm wiring. It takes 12v to trigger and its not worth PWM it on our cars.

AND, if I'm wrong tell me what the best position is to lock the cam at. However I am more than happy with the sudden 100hp increase in power when it kicks in....

Also no good comparing with the Puma, its totally different system. Puma is electronically controlled whereas the ST170 is mechanical....

Mine is setup as advised by Northamton Motorsport and it comes on at 1500rpm and above 30% TPS. This means its variable in that at WOT its at maximun and off on the overun.. oil pressure deals with the rest.

Theres no advantage in trying make it more complicated!

[Edited on 18/2/12 by coozer]

The ST VVC isn't just on/off, otherwise why would Ford give the car a seperate ECU to control the VVC and Inlet lengths. the engine oil pressure

is set by the relief valve in the pump and the solenoid lets varying abouts of that pressure to advance the pulley around, a fella on Turbosport got

his max power on the rollers at something in the region of 45-50 degs rather than 60degs that came from just switching it on.

Apart from that, yes the ports are taller as when I put the ST inlet on a blacktop it kept sucking the O ring seals into the inlet tract until I

refitted the old seals.

Regards Dan.

quote:

Originally posted by scutter

The ST VVC isn't just on/off, otherwise why would Ford give the car a seperate ECU to control the VVC and Inlet lengths. the engine oil pressure is set by the relief valve in the pump and the solenoid lets varying abouts of that pressure to advance the pulley around, a fella on Turbosport got his max power on the rollers at something in the region of 45-50 degs rather than 60degs that came from just switching it on.

Apart from that, yes the ports are taller as when I put the ST inlet on a blacktop it kept sucking the O ring seals into the inlet tract until I refitted the old seals.

Regards Dan.

quote:

Originally posted by silky16v

quote:

Originally posted by scutter

The ST VVC isn't just on/off, otherwise why would Ford give the car a seperate ECU to control the VVC and Inlet lengths. the engine oil pressure is set by the relief valve in the pump and the solenoid lets varying abouts of that pressure to advance the pulley around, a fella on Turbosport got his max power on the rollers at something in the region of 45-50 degs rather than 60degs that came from just switching it on.

Apart from that, yes the ports are taller as when I put the ST inlet on a blacktop it kept sucking the O ring seals into the inlet tract until I refitted the old seals.

Regards Dan.

correct the VCT is controlled by the cam phase sensor, rpm, tps and other sensors it is a continually altering the position of the camshaft

But its not a separate ecu. The main purpose of the vvt is for emission's.

quote:

Originally posted by baz-R

quote:

Originally posted by silky16v

quote:

Originally posted by scutter

The ST VVC isn't just on/off, otherwise why would Ford give the car a seperate ECU to control the VVC and Inlet lengths. the engine oil pressure is set by the relief valve in the pump and the solenoid lets varying abouts of that pressure to advance the pulley around, a fella on Turbosport got his max power on the rollers at something in the region of 45-50 degs rather than 60degs that came from just switching it on.

Apart from that, yes the ports are taller as when I put the ST inlet on a blacktop it kept sucking the O ring seals into the inlet tract until I refitted the old seals.

Regards Dan.

correct the VCT is controlled by the cam phase sensor, rpm, tps and other sensors it is a continually altering the position of the camshaft

so all of thoes reputable tuneing co.'s and meny experts in the aftermarket field are all wrong then?

i wanted to use a st170 with full vvc control with aftermarket ecu but everyone said it cannot be done as ford do it on and off!

inlet lengths are of no interst as i wanted to run throttle bodies

now if anyone can give me info on how to actualy do it and how it realy works im all ears as it is an engine upgrade im intersted in

[Edited on 28/5/13 by baz-R]

Money is better spent on getting longer duration cams. Then you will see around the 250bhp mark from the engine.

quote:

Originally posted by Rob Allison

Money is better spent on getting longer duration cams. Then you will see around the 250bhp mark from the engine.

Have you had a look at the Cat Cams for the ST170 engine, we are running them in a Mk1 Escort and they work really well.

http://www.catcams.co.uk/acatalog/Ford_ST170.html

Mk1 Escort with ST170 power

quote:

Originally posted by Digimon

Have you had a look at the Cat Cams for the ST170 engine, we are running them in a Mk1 Escort and they work really well.

http://www.catcams.co.uk/acatalog/Ford_ST170.html

Mk1 Escort with ST170 power

The valves don't need re-shimming unless you went for the crazy lift versions, great cams tho they really transform the engine

quote:

Originally posted by Digimon

The valves don't need re-shimming unless you went for the crazy lift versions, great cams tho they really transform the engine

quote:

Originally posted by baz-R

quote:

Originally posted by silky16v

quote:

Originally posted by scutter

The ST VVC isn't just on/off, otherwise why would Ford give the car a seperate ECU to control the VVC and Inlet lengths. the engine oil pressure is set by the relief valve in the pump and the solenoid lets varying abouts of that pressure to advance the pulley around, a fella on Turbosport got his max power on the rollers at something in the region of 45-50 degs rather than 60degs that came from just switching it on.

Apart from that, yes the ports are taller as when I put the ST inlet on a blacktop it kept sucking the O ring seals into the inlet tract until I refitted the old seals.

Regards Dan.

correct the VCT is controlled by the cam phase sensor, rpm, tps and other sensors it is a continually altering the position of the camshaft

so all of thoes reputable tuneing co.'s and meny experts in the aftermarket field are all wrong then?

i wanted to use a st170 with full vvc control with aftermarket ecu but everyone said it cannot be done as ford do it on and off!

inlet lengths are of no interst as i wanted to run throttle bodies

now if anyone can give me info on how to actualy do it and how it realy works im all ears as it is an engine upgrade im intersted in

[Edited on 28/5/13 by baz-R]

quote:

Originally posted by silky16v

quote:

Originally posted by Rob Allison

Money is better spent on getting longer duration cams. Then you will see around the 250bhp mark from the engine.

You need pistons as well, and have to get the valves re sized to match the lift duration

Ok bit of an old thread but I thought I would share CORRECT information, as in scoped, tested and analysed... the reason being we are developing a

standalone mapple VVT Controller for the ST170, which will be retialed via Chester Sport Cars.

1. The solenoid is actuated by 12V.

2. It is a PWM system the Frequency is FIXED but the DUTY alters.

3. The little box you guys are calling a separate ECU is NOT an ECU, it is merely an actuator drive for the variable length inlet.

4. Using just a varying PWM on TPS/RPM will not yeild the best results because the system is using oil pressure and its flow through a valve which

varies with temperature, load, wear etc. So this is how is its REALLY done:

The ECU finds TDC from the crank. It then follows the cam profile from the cam sensor to determine the cam angle. It looks up the desired cam angle

based on Load and Speed (and a couple of other factors) and then using a PID loop it adds or reduces the DUTY of the valve to get the cam to target a

commanded advance angle. Simples.

5. Switching it on or off like V-Tec will yield mixed results. I have personally seen an ST170 jump from 160bhp to 197bhp on jenveies on the Dyno by

turning it simply on and off during mapping. The problem is that due to other fluctuations the VE of the engine can change so much that the mixture

may go lean or rich, depending on lots of unmeasured factors (oil pressure and temp being two) That being said it does work, although a bodge.

Hence this ~£200+VAT controller being developed, which will turn a Megasquirt or an Omex 600 (or any other VVT lacking controller ECU) into a real

solution for this problem... and not cost £1000 to do it...

We will be looking for beta testers over the next few months and as always I always come first to the Locost forums as you guys are actually willing

to get your hands dirty!

Will keep you all posted

Matt

[Edited on 21/1/14 by mtechmatt]

[Edited on 21/1/14 by mtechmatt]

[Edited on 21/1/14 by mtechmatt]

Very interesting.........

My current build is using the Puma 1.7 engine which (as I understand it), uses the exact same system as the ST170 VVT.

Using the Alt fuction on the Omex you can also turn it off again at higher revs that (apparently) can give good results, although I don't profess

to understand why.......but as you say, this is not the way ford intended to use it.

My intention is to get the car on the road this summer so in the next few months will be getting the cars on the rollers.

For those interested in this subject there is stand alone VVT controller available already from DIYAutotune ( makers of Megasquirt ). Since posting this on another thread I have learned that some MX5 owners in the UK have used this successfully. Cost from memory is about $250 so around £200 in the UK. How applicable it is to an ST 170 Zetec or a Puma for that matter I do not know but I am trying to find out more. I gather there is a very active Megasquirt forum that might have more info but I have not followed that up yet.

John,

Its not compatible as the Mazda uses a track and hold method for PID/Duty control. that and the triggering patterns are completley different

Our system will initially support ST170 patterns but as out library of patterns increases (and the unit has USB frmware update) we aim to support an

array of patterns, Puma, Mazda, Toyota, BMW Vanos, you name it

Matt

Excellent news, I will follow this with interest. Keep us posted.

A little sneak peak at the ST170 VVT Controller

Looking good Matt. Will the fsq400 ecu have this built in?

Alan,

Yes as we are using the same processor family, anything we develop on either device will be cross compatible. ie if we work out BMW VANOS on the FSQ,

we can add that module to the VVT controller, and vice verca

Matt

Jenko, I have been told that the ST170 VVT and the Puma VVT are not the same although the operating principles might be. The Puma is ( was ) sourced from INA, the ST 170 I don't know. Perhaps most significantly the Puma operates off 5 volts ( certainly Omex think so and others have achieved successful operation using a 5 volt aux out signal ). It seems the definitive answer from Mtech is that the ST170 operates of 12 volts. Anyone able to confirm/clarify?

Yep the st170 is 12v.

looking real sweet there Matt

willlook forward to seeing the benifits from this little box of tricks!!

quote:

Originally posted by johnH20

Jenko, I have been told that the ST170 VVT and the Puma VVT are not the same although the operating principles might be. The Puma is ( was ) sourced from INA, the ST 170 I don't know. Perhaps most significantly the Puma operates off 5 volts ( certainly Omex think so and others have achieved successful operation using a 5 volt aux out signal ). It seems the definitive answer from Mtech is that the ST170 operates of 12 volts. Anyone able to confirm/clarify?

Indeed it would be 12v.

The Aux out you speak of would be a switched ground, not switched live, so its up to the vehicle to power the solenoid.

Its going to draw maybe 1 amp, so that means we need an entire secong regultor to give it 5v from the PCM... easier (by design) just to run it off 12v

as the switching mosfet in both cases would be the same. Less cost, and ford like that

The cam pattern appears to be a 4+1 (same as the ST170) as far as I can tell so I will be looking forward to trying it out on this also.

That being said, the Puma engine with a set of Bike carbs and a NODIZ (with VVT) and you have a very light, very revvy little motor that can be quite

torquey with correct VVT operation (or flat and fluffy without)

Could be an interesting kit to put together...

We have an ST170 focus here for development, and once we have confirmed the systems operation Chester Sports Cars will be combining it with a an ST170

and bike carbs and will give some rolling road figures, comparing no VVT, the classic 'on at 1300rpm' method, and finally properly mapped

VVT control. Should be interesting!

Regards,

Matt

The Aux switches in a ground as you mention....just to be extra carful, I Actually used the omex Alt control to drive a relay rather than direct from the omex...I think it would have coped but, did not want to risk it.

quote:

Originally posted by mtechmatt

4. Using just a varying PWM on TPS/RPM will not yeild the best results because the system is using oil pressure and its flow through a valve which varies with temperature, load, wear etc. So this is how is its REALLY done:

The ECU finds TDC from the crank. It then follows the cam profile from the cam sensor to determine the cam angle. It looks up the desired cam angle based on Load and Speed (and a couple of other factors) and then using a PID loop it adds or reduces the DUTY of the valve to get the cam to target a commanded advance angle. Simples.

Thanks for the recent replies guys, I am slowly beginning to understand this but I am outside my comfort zone! Looking forward to results Matt. Think you could be on to a winner.

John, cheers, getting there

i thought this was a small unit?

Dont think i will fit that big red box under my dash!!!

only joking matt.

If you are looking for a bare engine in a car to try it on i could bring mine down?

hehe its designed to go on the passenger seat. The extra power is worth the space lol

We will be trailing the unit on a car from Chester Sports Cars, they will be supplying the ST170 variant exclusively after launch so be sure to peg

your interest with them...

Definitely the more the merrier though as you cant beat loads of testers covering loads of miles in a short time

Got a delete kit fitted and running. The engine is far smoother and revs better than with a switched off/on vct.

Still trying to find the best point for the cam timing. Without changing the cam duration big power gains are limited.

But using the VCT right will give more low down power. Also if your turboing the engine you can reduce the dynamic compression ration at high revs

without the need to lower the actual static CR.

The box looks a good option. It would be to see how altering the cam angle does alter the power

Rob,

Indeed I am looking forward to actually doing the basemap calibration.

My intention is to use our dyno and do MANY runs at varying throttle % and varying Cam Positions (I will be able to 'fix' cam angle with the

software during testing) and then plot these graphs over one another to give the optimum setup (pick the bet top end and low end settings etc for each

throttle position/speed) for NA/carb'd ST170 engine cam profiling.

Will be very exciting and I hope to be on the dyno within 2 weeks with the beta units....

That and as you say with turbocharged cars for a mapper it is excellent.. no more DTI to find the best 'average locked position', just

straight forward 'what works best for each throttle position/speed' on the dyno...

Matt

PS rob our gunea pig will be a carbed ST170, so will report the best 'average angle' for you to set the cam to (if yours is NA also), seeing

as we will be doing lots of experimenting!

Cheers

[Edited on 13/2/14 by mtechmatt]

Look forward to it.

Yes mine is N/A, on Direct to head throttle bodies.

Matt have you mapped the St 170 on a DTA s60? Looking for someone reasonably local to me to tune my kit car...

Dave B

Dave, sorry no I have not, if I am honest Im not too keen on DTAs software, although I am happy to help I would reccoemend a tuner more used to that

particular ECU system...

Cheers,

Matt

Hi Matt, you may know the following in which case please ignore - but it was news to me.

At www.diyautotune.com/vvtuner/tuning/htm is a map developed with their controller and software for a 1.8 Mazda Mk 2. I would hazard a guess that it

could prove pretty generic for similar 4 cylinder 16 valve engines. Your tests will prove or disprove this, we shall see.

To me it is interesting from several points of view, most obviously that when you get off idle and above 50 mPa load the map becomes more or less

speed dependent only. If you are into Taguchi design of experiments this might offer you some shortcuts and save a lot of time.

Good luck and keep us posted.

John, indeed saw this a while ago.

The difference mainly is the Mazda uses a track and hold oil valve (there is no spring return) whereas the ST170 tries to return to 0 if the valve is

closed...

But yes good pointers.

Also found on the St170 the VVT solenoid is not driven at all until 1320rpm by the OEM ECU

Matt

Will you be able to get the standard ecu cam angles on a plot

Rob, I would guess the only way of knowing what the standard OEM map looks like is by interrogating the OEM ECU. There are a lot of input variables and I guess the Strategy has more to do with emissions and fuel economy optimisation, especially in the low load regimes, than actual power/torque maximisation. Until recently I was under the impression that the Ford EEC V could not be read/modified but I have discovered that is not the case. There is a forum - www.EECTuning.com and even a book about it. Just shows how little I know - but I am trying to learn.

i have had information that updated codes are there for Genuine ms3 and possibly 2 (ford vvc cam trigger patterns) are there to run st170 vvc

with pwm channel.

been as im already getting 165bhp form my own 1800 silvertop zetec setup(std head,valves etc.) i cant see the point of changing it all at the moment

unless somthing comes up realy cheap

ps: please dont beleave anyone saying the inlet patterns (gasket area) are the same between normal zetec and st170's there is an big missmatch in

port hight!

Chaps,

we have it working

We have just done a data plot of standard cam angles on a full power pull in 3rd gear.. Letting the OEM ECU control the VVT and us just record the

angles.

Will post the graph shortly.

You will be impressed...

Well done- I'm interested to see the results!

The definitive ST170 VVT information post...

http://motorsport-electronics.co.uk/forum/viewtopic.php?f=18&t=11

Any reason for the plot stopping at 5000 rpm

Also does the cam move over a 45deg range or 60deg

[Edited on 25/2/14 by Rob Allison]

Appears to move over 45* We can move it further with direct control...

Plot carries on, stays level to 7k (excel for you!)

Brilliant work! I did not realise you would be able to directly measure the oem plot, I thought you were going to generate your own map from scratch. This obviously gives you a running start for future work. Great stuff, keep us posted.

Very interesting and great work....do you think there may be some 'emissions based' mapping for the cam also?.

What would be supper interesting is to see the same plot with the power / torque, this would illustrate how the timing changes the torque.

So, how would this system integrate with an omex 600?.....Are there many connections?....must admit...im interested.

Cheers guys...

As to the Omex 600.. it will work as it is completely independent.

You simply 'splice' into the crank sensor lines (as we did on the OEM car) and then connect the VVT solenoid and the cam sensor, thats

it.The omex wont know its happening, only you will need to remap the omex (or whatever ECU your are running) to suit the now better

'breathing' engine.

You would then of course map the Omex using their software and our system using our software and USB, so you could have both tuning interfaces open at

the same time, and thats it, done.

Definitely some emissions stuff in there. They fully advance the cam on over run.

Will be doing LOTs of dyno data and printouts over the coming days, to capture the OEM curves for differennt throttle positions, thus building our 3D

basemap.

Matt

I've guessed fora while that the cam remains fully retarded at tick over to reduce overlap there for stopping un burnt fuel escaping and keeping the emissions down at that rpm.

Be intersting to see the difference between emmisson controlled cam angles and the raw power/torque curve.

I have only interest in one curve but understand its different for others!!

BIG UPDATE LOTS OF GRAPHS!

http://motorsport-electronics.co.uk/forum/viewtopic.php?f=18&a

mp;t=11&p=16#p16

I'm a layman, so bear with me

I've currently got a 2.0 zetec running MBE and bike throttle bodies.

Is my understanding that I can fit this setup to an ST170 engine, but then tap in your VVT controller for the best of both worlds?

Dave,

Correct

Matt

Awesome. Got a price yet? LOL.

Saves me messing about putting a duratec in - I'd be very interested to see what gains could be had on a TB'd ST170 unit.

The system is £240inc, if you are up north you can source it from Chester Sports Cars, and they can give more local support if needed, if nearer us

the we can supply for you.

Cheers

Matt

Dave inlet and exhaust are slightly different on the st to the zetec. You will need to alter them both to fit the st. Inlet ports are higher and bigger, exhaust is also larger but same place.

First off, as previously mentioned...what a great article, you need to get this in PPC mag...the work you are doing is great and very informative.

I have a question though :-)

I couldn't agree more that the fully controlable setup is always going to be the best......But..and here me out....assuming the you have not

remapped with the vvt on /off experiment, im not surprised at the result. To optimise this set you would undoubtedly need to map the fuel (and maybe

ignition) to make the most of it. So, what would be interesting is to see what the afr is doing when the vvt is simply turned ON. and then to map the

fuel accordingly....Worth a punt?.

quote:

Originally posted by rhinopower

Running vvt leaves the cam at 90degrees at rest, and 130 degrees at advance, neither of these are the cams peak power figure. I understand the reasons for running it, and I did previously, however there is a better way of doing it.

quote:

Originally posted by coyoteboy

quote:

Originally posted by rhinopower

Running vvt leaves the cam at 90degrees at rest, and 130 degrees at advance, neither of these are the cams peak power figure. I understand the reasons for running it, and I did previously, however there is a better way of doing it.

If you mapped it correctly it would not run lean and should provide better results, it makes absolutely zero sense for a manufacturer to add huge complexity to make a poorer performance. The whole point of vct is to allow better performance and efficiency at low revs but provide correct timing at high revs too, why would Ford make it so it's worse at both if it didn't have to? Your suggestion that when activated it goes lean suggests you were not mapping to account for this, a simple automatic table switch should work and could match ignition timing to.

I guess the point is.....The on / off method, although clearly not optimum is not used with the ford ecu, it's typically used with aftermarket

ECU's that are mapped accordingly to compensate for when the cam turns 'on'.

I think the real test is to understand how the on/off method works on a fully mapped ECU. Also I assume you mean Lambda sensor rather than MAF for the

compentsating. Again, I would imaging the Lambda comensation to not be able to keep up with the on / off function.....Im far from an expert however,

so just adding more discussion points to the experiment. Keep up the good work.

quote:

Originally posted by Jenko

I guess the point is.....The on / off method, although clearly not optimum is not used with the ford ecu, it's typically used with aftermarket ECU's that are mapped accordingly to compensate for when the cam turns 'on'.

I think the real test is to understand how the on/off method works on a fully mapped ECU. Also I assume you mean Lambda sensor rather than MAF for the compentsating. Again, I would imaging the Lambda comensation to not be able to keep up with the on / off function.....Im far from an expert however, so just adding more discussion points to the experiment. Keep up the good work.

quote:

Originally posted by BaileyPerformance

quote:

Originally posted by Jenko

I guess the point is.....The on / off method, although clearly not optimum is not used with the ford ecu, it's typically used with aftermarket ECU's that are mapped accordingly to compensate for when the cam turns 'on'.

I think the real test is to understand how the on/off method works on a fully mapped ECU. Also I assume you mean Lambda sensor rather than MAF for the compentsating. Again, I would imaging the Lambda comensation to not be able to keep up with the on / off function.....Im far from an expert however, so just adding more discussion points to the experiment. Keep up the good work.

Matt is correct, its the MAF reading that will change when the cam angle is changed, as the air flow will change when the cam is moved.

The lambda on a standard ST is a narrow band, so is not used after a give point (open loop)

Matt did you manage to alter the VCT without the standard ecu reading any fault codes for the cam not being in the correct position the ecu wanted.

Controlling the VCT with this box is one of the cheap route to using the ST engine. But there are going to be no big gains unless more cam duration is

used i.e. new cams.

From reading about another ST build which has head work,cams, pistons and rods done. They have still not managed over 198bhp. But its still on the

standard inlet. So it looks like the inlet may be far more restrictive to the engine.

quote:

Originally posted by Rob Allison

Matt did you manage to alter the VCT without the standard ecu reading any fault codes for the cam not being in the correct position the ecu wanted.

Controlling the VCT with this box is one of the cheap route to using the ST engine. But there are going to be no big gains unless more cam duration is used i.e. new cams.

From reading about another ST build which has head work,cams, pistons and rods done. They have still not managed over 198bhp. But its still on the standard inlet. So it looks like the inlet may be far more restrictive to the engine.

The results are in...

We carried out the testing on this Mk1, fitted with 6R carbs and a NODIZ for ignition management...

The below are the AMAZING RESULTS. The RED is the normal switch on at 1500rpm Method, the BLUE line is running the VVTPro with a factory VVT advance

curve. We never did any mapping, just plugged it in..

10ft/lbs gain for the majority of the graph, with even more gains at the end, and 21bhp overall power gain...

With finer PID tuning and more mapping we expect even more gains, but I think out of the box, that'll do donkey, that'll do!

Wow that's an epic increase.

Going to find something with an ST engine on bodies next?

Dave,

Thats the plan

if anyone has one, and wants it mapped for free I(I assume already running an OMEX600 or a megasquirt, and is happy to wire a beta unit into their

car, and can get down to wiltshire, PM me

damn having a silvertop

Matt,

Interesting work - is that power at the back wheels or the engine?

If at the engine then it would seem little point in using an St170 engine when we have seen over 160BHP using bike carbs and 175BHP on Jenveys on a

stock black top.

We have dyno'd a totally standard ST170 and they do make close to 170BHP, that's with a CAT and all factory electronics and hardware.

So, there is a problem with the Escort shown in your post - maybe the carbs are too small? was the fueling spot on?

We have noticed the exhaust system is critical on a blacktop, i would assume more so on than ST170 - the system must be 2.5" with an free flowing

manifold - the stock ST170 one is very good. (could be modified for RWD?)

quote:#

Originally posted by BaileyPerformance

Matt,

Interesting work - is that power at the back wheels or the engine?

If at the engine then it would seem little point in using an St170 engine when we have seen over 160BHP using bike carbs and 175BHP on Jenveys on a stock black top.

We have dyno'd a totally standard ST170 and they do make close to 170BHP, that's with a CAT and all factory electronics and hardware.

So, there is a problem with the Escort shown in your post - maybe the carbs are too small? was the fueling spot on?

We have noticed the exhaust system is critical on a blacktop, i would assume more so on than ST170 - the system must be 2.5" with an free flowing manifold - the stock ST170 one is very good. (could be modified for RWD?)

According to Ford spec's, the ST170 produces 170PS (168bhp) and the ST220 makes 222PS (219bhp) so the figures aren't totally meaningless. I

guess an ST219 may not have sold quite as well......

Hmm, IIRC Autodata liosts the St170 as around the 155 mark, certainly all we have ever seen anyway...

Our stock St170 focus we dynoed at the start made sub 150  And that is a normal car bought for testing, with no modifications at all

And that is a normal car bought for testing, with no modifications at all

Matt

Matt,

I have an ST170 on jenvey 48's dry sumped gagging for a tune BUT as contacted you before I have it running on a DTA S60.... I am in

Horndean so a couple of hours away.... :-)

Dave B

Dave,

Yes unfortunately im no DTA expert

Cheers,

Matt

The question is, will it go viral?

quote:

Originally posted by mtechmatt

Hmm, IIRC Autodata liosts the St170 as around the 155 mark, certainly all we have ever seen anyway...

Our stock St170 focus we dynoed at the start made sub 150And that is a normal car bought for testing, with no modifications at all

Matt

quote:

Originally posted by mtechmatt

Funny how even though Ford never stated the 170 meant 170bhp, people assume it be...

quote:

Originally posted by mtechmatt

A mondeo St24 makes abit more than 24bhp

I still stand by my previous comments - The On/Off comparission is not a true representation as the engine was not mapped accordingly around the

function of the VVT solinoid.

So, at the moment, we can't really say if it works or not as no doubt the fuelling would be all over the place if using a standard ford ECU.

The utimate comparisson is using an after market ECU with your variable cam timing system - mapping it to it's full potential. then doing the

same but just using the on/off - of course it would then need re mapping.

For what it's worth, I'm still sure the variable would be better, but at least we would know by how much.

all good though, and a great experiment.

[Edited on 12/3/14 by Jenko]

quote:

Originally posted by BaileyPerformance

quote:

Originally posted by mtechmatt

Hmm, IIRC Autodata liosts the St170 as around the 155 mark, certainly all we have ever seen anyway...

Our stock St170 focus we dynoed at the start made sub 150And that is a normal car bought for testing, with no modifications at all

Matt

155bhp at the wheels would be correct, about 20bhp loss through transmission is normal.

The one we tested made close to 170bhp stock, we also tested a stock 2.0L focus mk1, was within 5bhp of what ford stated.

Same goes for my standard mk1 focus RS.

The point I'm making is Ford do not lie about power outputs, this is true right back to pinto powered escorts, we did a stock RS2000 and it make 105bhp, spot on.

We have stripped a couple of ST170 engines, looking at the ports compared to a black top you can see these engine will make power - if a stock blacktop will make 160 an ST should make 190 with decent induction and your VVT device.

Interesting point on comparison of ST and blacktop heads the exhaust valves and ports are the same sizes. Considering the inlets are very different I suspect this limits power on the ST and is part of why both engines need a good exhaust system.

Here is a quick video on how VVT works...

https://www.youtube.com/watch?v=O5qkdFk50Zg&feature=youtu.be[/youtube]

For those interested i have some information on the differences with the zetec and the ST170 duratec(zetec)

Engine

The 2.0L Duratec ST engine is based on the 2.0L Zetec-E engine. In comparison to the 2.0L Zetec-E engine the modifications are:

Cylinder Block

part modified to include piston spray jets. (Some zetecs have these)

Cylinder Head

Inlet Port: - High flow design with new manifold break-out.

Exhaust Port: - Standard port but with secondary air feed to the back of the exhaust valve.

Water Jacket: - Revised flow around ports.

Oil feed arrangement for variable valve timing installation.

Incorporation of VCT (variable camshaft timing) solenoid in front camshaft bearing cap.

Inlet Valves

33.5 mm diameter with revised spacing to maintain bridge material and longer length for new port.

Exhaust Valves

Standard diameter but longer to commonise tappet with the inlet side. sodium-filled exhaust valves

Inlet Camshaft

Increased lift and duration with variable timing. 277/265 lift 10.95mm

Trigger wheel fitted to indicate cam position.

Exhaust Camshaft

Increased lift and duration. 230/220 lift 9.85mm

Tappet

Series of sizes commencing with unique graded part to suit new length valve and revised cam profile.

Valve Springs

Inlet and Exhaust unique parts to suit new valve lengths and revised cam profiles.

Power Cell Assembly

Piston with 20 mm diameter gudgeon pin.

Connecting Rod (139.19mm) - Forged fracture-split design.

Top piston ring – Internal bevel to reduce blow-by of combustion gasses and negative ovality of the ring ends to reduce wear.

Cam Cover Assembly

Re-styled and revised to suit new VCT solenoid installation. Cam Cover and Gasket Assembly.

Upper Timing Belt Cover Assembly

Re-styled to include VCT pulley.

Front Engine Mount

Mounting studs moved to clear VCT pulley.

Alternator Bracket

Modified to accommodate revised engine mount.

Intake Manifold

Made up of two assemblies replacing the single piece manifold with fixed length tracts.

Plenum Assembly

Housing Assembly-Manifold-Injectors

Variable-length intake runner design.

The unit is in the short runner position with the engine off and then switches to the long runner position when the engine starts. The runners then

switch to short runner position above 6000 rpm.

Throttle Body

Modified 63 mm diameter part.

Injectors

Increased flow items specified as 224.8 g/min at 2.7 bar (normal fuel rail pressure)

Fuel Rail

Redesigned part with integral damper and no fuel return connection. The fuel inlet to the rail has been repositioned requiring a new fuel feed hose

assembly.

Flywheel Assembly

Dual mass flywheel.

Clutch Assembly

Friction plate – increased diameter.

Pressure plate – increased diameter. 228mm

Oil Cooler

Modine type.

Variable Cam Timing System

Variable Timing Unit Assembly

Solenoid Assembly

Oil Separator Assembly

Internal changes to improve performance under high cornering loads – to be introduced onto base engine.

Exhaust System

Tuned 4-2-1 system with the catalyst located under the oil pan.

Quite a bit changed on the st170 engine then...more than I thought...great info.

I was just reading back through the thread, and the real conclusion to the on / off function of VCT, is it seems to work fine as on / off, as long as

your ecu has the function of turning it off again at higher revs, else, as per the findings, you loose lots of peak power.

[Edited on 16/6/14 by Jenko]

Interesting that it was chosen to present the 10 degree fixed advance graph here and not the 30/40 graph.

It would have also been more representative of comparison if you had taken a run of the Escort at a fixed 30/40 - i.e. the £100+ fixed mechanical

option against the benefit of your box at £240+ As you had already proven that the max advance provides rubbish results.

Hopefully 30/40 fixed V the PWM would have shown that you could offer a real world benefit in the 2000- 4000 RPM range as well as the pub bragging

rights of keeping the maximum power capability for the extra cash and complication.

Mate is working on a turbo ST170 and has the lock out kit to fit but I have given him your company detail to discuss the box with you.

Cheers

Andrew

You don't get any extra power by running the vct but you gain a little extra torque at 3 to 3.5k revs. For me the extra torque is not worth the

price. Yo may as well put the cash towards a set of cams and got for over 200 bhp which you'll not get even with the box of tricks.

With the vct just switched on you advancing the cam 9 deg past the point ford control it to and about 30deg past the best power point.

There is a massive difference with the cam locked at the right point.

You "may" not get any extra top end but it is quite clear that you will get a great deal of extra power (torque is the best sort of power -

ask F1) - the area between the two graphs is where you should be focused, and you have to go through every RPM from Idle to get to that magic maximum

and the less there is on the way the slower you will get there. That's why those that appreciate it do not dismiss that area.

If you leave you your driveway with clutch dumped at 5000 rpm and your box ratios never drop below that then fair play - lock and enjoy.

A lock out kit is £100 + the hassle of fitting it and finding that sweet spot for your set up - good luck with that . To plug in a box for a £150 more

and potentially (yet to see proof mind) get all that available power in that 2000-4000 area that could be worth every penny. I would rather have a

simple map change on the box to re-timing cams any day of the week.

There is only a massive difference between locked (at the correct point for your car) and uncontrolled. You would need a PWM input to find that

control point to lock it at. and if you have fitted Verniers to make the job easier you have already spent far in excess of the box and for ultimately

less power ......

The only option that is better value than the box is the fixed "if" there is a cam timing at 38.678 degrees that magically works for every

installation providing more power at all RPM.

If going for power then you could argue then dont use an ST170 with cams - just fit a Duratec and go from there - but the point being made is that

there is a nice little box that appears to solve the issue of good power from the ST as standard with a lowish cost and real world use.

Hopefully a better Dyno back to back will emerge.

quote:

Originally posted by Rob Allison

You don't get any extra power by running the vct but you gain a little extra torque at 3 to 3.5k revs. For me the extra torque is not worth the price. Yo may as well put the cash towards a set of cams and got for over 200 bhp which you'll not get even with the box of tricks.

With the vct just switched on you advancing the cam 9 deg past the point ford control it to and about 30deg past the best power point.

There is a massive difference with the cam locked at the right point.

Locking kit is £35 not £100+ and you don't pass 3500rpm more than once accelerating from a stand still. Unless you short shift

Just by running on/off you get a big gain in power right from 2000rpm up until 5500rpm, right where you want it.....this can be done with most aftermarket ecu's.

The cam advances too far by turning it on. It moves 60 degs, 30degs too advanced. You loose out on power and torque.

Hence why it needs turning off again at 5800rpm, you then get another kick in power at the top end of the rev range.