transmission tunnel idea. opinions...

JoelP - 30/7/04 at 08:17 PM

hi all. I had an idea relating to transmission tunnels, that could make them lighter and safer too maybe.

basically, normal tunnels have little contribution to the chassis rigidity. so the only real reason to keep it is to contain the prop in the event of

a failure. Broken props are especially because they flail.

My idea is to replace the usually tunnel with 4 simple bands of metal, curved to match the prop shaft and about 5mm away from it. (obviously this is

only possible on fixed diff cars). the bands would be n shaped, and made from 3x25mm strips, bolted to the chassis floor. the 4 brackets would be

positioned evenly along its length, ideally so that any failure would leave the longest part held in by 3 brackets.

the reason that i think 3x25mm strips could contain a prop is that, by holding the broken prop close to its axis of spin, the 'flail' effect

is reduced. IMHO a prop held precisely on its spin axis would have no force at all against its restraints.

i appreciate this idea isnt for everyone, but i thought it worth mentioning cos the saved weight could be used up in bigger tubes at the chassis edges

(this would help stiffness significantly in my opinion) or simple saved altogether to keep weight down.

thoughts anyone? feel free to call me a deranged lunatic!

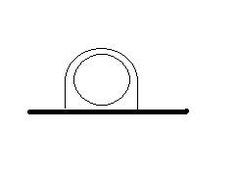

JoelP - 30/7/04 at 08:19 PM

like this but closer:

Rescued attachment shitbox1.JPG

pbura - 30/7/04 at 09:36 PM

Joel,

The structural analysis gurus have found that a lot of stiffness can be added to the Locost by enclosing the tunnel and tying it in to the rest of the

chassis at the front and rear. See kitcaranalysis (by our very own Cymtriks) and Final Thesis documents here:

http://locost7.info/mirror/chassis.php

IIRC, the tunnel doesn't even need upper tubes if welded all around. Making the tunnel out of arched sheet would look pretty darn good, IMO, and

would make a nice shape to put your guards into. I'm reading your drawing as being not so much strips as flat sheet metal shapes that would fill

the tunnel.

The guards sound like a good move for a BEC in particular.

Pete

ReMan - 30/7/04 at 09:43 PM

Dear deranged lunatic,

I think some of your points are very valid. I was pondering this sort of idea myself but on a less radical basis, to try and contain a prop should it

break.

I thought that the tunnel was quite a structural component having seen debate on the benefits of fully panelling and rivting it to make the chassis

even more rigid.

I was thinking along the lines of some inner plates, similar to your diagram but which could be mounted inside the tunnel before closure or even the

tunnel cover, same profile but done in stainless steel plate so as to be able to withstand said flailing prop?

JoelP - 30/7/04 at 09:46 PM

ok, i'll accept that the tunnel might add strength! i cant personally see how it does much though, but thats not really important. The

brackets/guides still seem a good idea though! my next car will be a middy with a roof though, so it doesnt really matter!

ReMan - 30/7/04 at 09:49 PM

how do you get a pic to show?, what format does it need to be in ?

it is late and Stella is my bestest friend

ReMan - 30/7/04 at 10:04 PM

Oh well, i`ll make it my avatar whilst i`m on holiday!

Hows that for really bad drawing!

Cheers

stephen_gusterson - 1/8/04 at 09:25 AM

I have read that caterham use simple bands.

I have gone for a box section tunnel, braced into front and rear bulkheads, cos I recon this is a useful backbone, especially as my car has doors.

you can gain more hip room by tapering the top of the tunnel towards the rear. you can see this effect if you look at my tunnel cover pics i posted in

the upholstery section a few days back

atb

steve

[Edited on 1/8/04 by stephen_gusterson]