Welding trials near disaster

Mansfield - 5/1/07 at 07:56 PM

I am working in an integral garage, any uncontrollable fires and my house burns down. My insurance company are OK with this but obviously SWMBO is

not.

I have water/sand/hosepipe/DP fire extinguisher all at the ready.

I was not expecting to have a fire before I even started welding.

When changing my wire over to 0.6mm, I missed the wire liner (it had moved) and it fed through to the electrical side of the welder. It must have

earthed on something and flames came through the side vents.

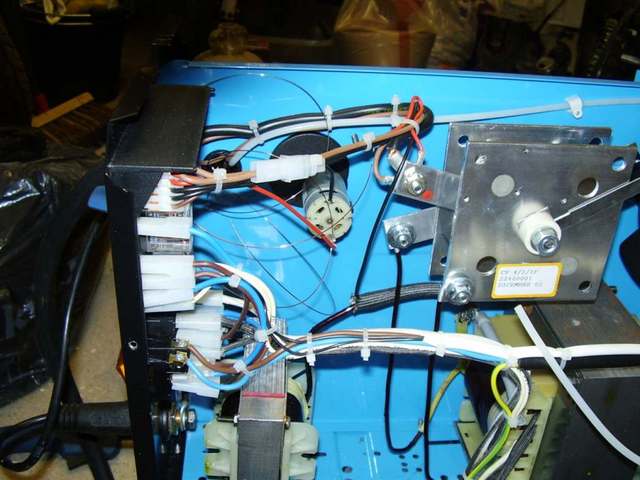

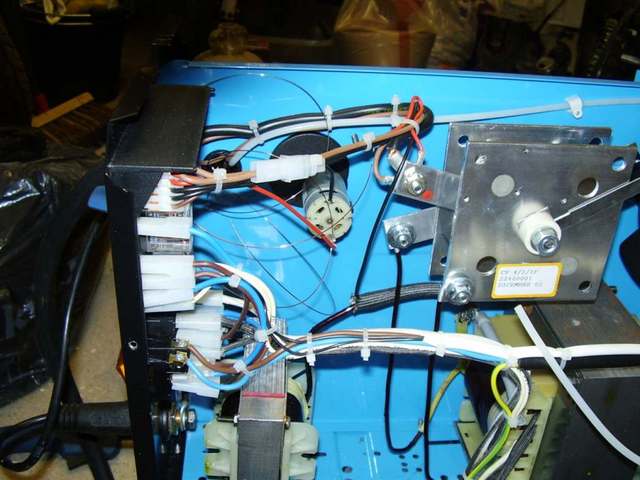

Picture is not that great but you can see the wire coming through the grommet for the gas feed. There was a lot more wire, I took the picture after

cutting out the stuff that had wound round the big magnet things.

Needless to say I s**t myself. I didnt think something like this would be possible - but it wont be happening again at my house.

Rescued attachment P1050033a.jpg

caber - 5/1/07 at 08:17 PM

Oh dear! maybe gas welding isn't so bad after all

You could try TIG it is a nice gentle contained process no spatters and bangs, machine not likely to spontaneously combust as no wire to head off in

dodgy directons!

Caber

Mansfield - 5/1/07 at 08:24 PM

I cant afford TIG.

JohnN - 5/1/07 at 08:34 PM

Oxy-acetylene must have a far greater disaster potential - my wife isn't bothered by my electrical welding, plasma cutting, grinding, sparks

everywhere activities, however, the mere presence of two full size gas bottles is a big problem to her in our (integral) garage.

Would an earth leakage circuit breaker not solve your concerns for short circuits (obviously to earth)

RazMan - 5/1/07 at 08:48 PM

Birds nests are a common occurrance with some welders - my SIP 150 doesn't have the power to produce one though - it just stalls the motor

Mansfield - 5/1/07 at 09:45 PM

This one off event for me, birds nests I could live with on the wire side but not the power side. It was my fault it happened but this must have

happened to someone else some where in the world, I doubt this was even considered during the CE process.

My Dad has a spare pair of full sized bottles that I could have but I have declined the offer - maybe if the garage was not beneath my bed.....

caber - 5/1/07 at 11:24 PM

When did anyone ever remember a gas bottle going bang? The only time they pose a real threat is when the building they are in is already on fire!

people seem remarkably unconcerned about butane bottles in cabinet heaters in the living room, these are far more fraigile and can be very amusing in

a bonfire

Oxy acetelene is no more likley to cause fires than any other welding system, bits of white hot metal can set anything on fire !

TIG inverters are pretty much as cheap as MIG sets these days!

Caber

Peteff - 6/1/07 at 12:13 AM

It can't do it unless you are there to press the trigger and you only needed to switch it off at the socket to stop it. We will not make a drama

out of a crisis, as they used to say in the adverts. I've had worse happen with electric kettles and hairdryers inside the house and unless

there's a lot of flammable material near the welder it's not going to spread anywhere.

edit:- I missed the wire liner (it had moved)

When threading new wire take the tension off the feed roller and push the wire a foot into the liner by hand. Remove the contact tip, put the tension

back on and switch on then use the trigger to advance it till it appears at the gun. Don't look down the end to see if it's there yet

[Edited on 6/1/07 by Peteff]

daviep - 6/1/07 at 12:57 AM

quote:

Oxy acetelene is no more likley to cause fires than any other welding system, bits of white hot metal can set anything on fire !

True white hot metal can start fires but generally electric welders don't explode (acetylene cylinders) or cause spontaneous combustion

(compressed oxygen)

Acetylene is completely different to ALL other fuel gasses in that it is very unstable and can decompose with frightening consequences. Check

here for a bit of advice from the experts. Guaranteed to surprise a few folk I bet.

Syd Bridge - 6/1/07 at 11:53 AM

I use oxy/propane for cutting and brazing.

Far safer and a little gentler to use. Still does the job though.

Cheers,

Syd.

caber - 6/1/07 at 04:20 PM

I was assuming that you are using the appropriate lighting techniques and at least non return valves if not flashback arresters. Has anyone on here

ever had a flashback that set off a cylinder? Has anyone here ever spoken personally to someone who has had an incident with an acetylene cylinder? I

never have!

How about people who have set something on fire while arc welding? I have and almost everyone I know who welds has done, the glass in an arc helmet

supresses the colour of flame very effectively so often you are not aware of the fire until you have stopped and lifted your helmet for a look

Caber

[Edited on 1/6/2007 by caber]

Alex B - 7/1/07 at 04:42 PM

If everything is properly set up the next concern on the list with acy. is to keep the bottle stable in a proper chained trolley. We know what happens

if a cylinder falls and the pressure valve fractures.

Alex

Peteff - 7/1/07 at 09:11 PM

Acetylene isn't under pressure, it's dissolved in a catalyst and is about 20 bar. It's the oxygen that is a danger if the valve gets

knocked off as it becomes a torpedo.

NS Dev - 7/1/07 at 09:51 PM

quote:

Originally posted by caber

I was assuming that you are using the appropriate lighting techniques and at least non return valves if not flashback arresters. Has anyone on here

ever had a flashback that set off a cylinder? Has anyone here ever spoken personally to someone who has had an incident with an acetylene cylinder? I

never have!

How about people who have set something on fire while arc welding? I have and almost everyone I know who welds has done, the glass in an arc helmet

supresses the colour of flame very effectively so often you are not aware of the fire until you have stopped and lifted your helmet for a look

Caber

[Edited on 1/6/2007 by caber]

We had an acetylene bottle "problem" (i..e bottle got all excited and started making noises and getting hot) at work. Fire brigade were very

straight forward about it, stick it in the biggest cool water tank we had on site and move everybody out of that area. Leave it there for several

hours. if it goes bang, it would have anyway, if it doesn't, well done!

It didn't!

I also have had the dubious pleasure of seeing an oxygen bottle go through two walls, one of them reinforced concrete, after it fell against an anvil

and some pallet racking. That is serious, never risk a fallen over cylinder, they mean business!!!

scudderfish - 8/1/07 at 01:23 PM

OK, I know absolutely nothing about this, so this is very likely a dumb question but....

If falling cylinders are so dangerous, why not store them on their side?

iank - 8/1/07 at 01:32 PM

Different reasons for both Acetylene and Oxygen/other gasses. From Wikipedia

http://en.wikipedia.org/wiki/Oxyacetylene

"Never lay an acetylene tank on its side while being used. An acetylene tank contains acetone in which the acetylene is dissolved. If the tank

was laid down while being transported, it must be set upright, valve on top, and given enough time (>30 min) for the acetone to settle back into

the sorbent. If these precautions are not followed, acetone may be drawn into the gas lines, thus creating a space in the top of the acetylene tank

devoid of sorbent (kapok, bunting, or acetone). If this void space becomes large enough, the gaseous acetylene in the void may explosively decompose

inside the tank causing damage to life and/or property.

Never lay a propane or other liquefied gas tank on its side while being used, as in the tank the gas is liquefied by pressure, and this liquid would

start to come out through the valve."

I suspect NS Dev's misbehaving cylinder had started doing this, but was caught in time.

p.s. be careful of acetylene and follow the safety procedures (I know the gas welders here know what to do). On Brainiacs The caravan they blew up

with oxy-acetyene was the most impressive

See this for people who don't treat it with respect http://www.boingboing.net/2006/02/23/acetylene_filled_bal.html

[Edited on 8/1/07 by iank]

ned - 8/1/07 at 02:21 PM

I remember last year popping round to find a very white James in his garage having knocked over a mig bottle of argoshield a few minutes before hand,

he had (luckily) only sheared the regulator off whilst the bottle was turned off with the key...

Ned.

Aboardman - 8/1/07 at 03:31 PM

on mythbusters they sent a oxygen bottle through ablock wall in a controlled way, it went clean through and nearly went through the next wall,

Peteff - 8/1/07 at 06:10 PM

The oxygen bottle torpedo was part of the safety video when I was learning to weld. It was spectacular to say the least.