Sheet metal Folder

Schrodinger - 2/4/06 at 05:03 PM

Does anybody have a set of plans to build a sheet metal folder?

907 - 2/4/06 at 06:00 PM

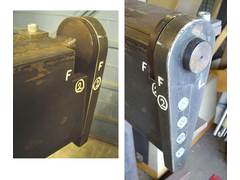

I made one from offcuts from work.

A length of channel, length of bar, codged up hinges for the ends, and box for legs & handles.

A clamping bar on the top held on with G cramps.

It'll bend 1.2 stainless, a metre long, or 1.5 mild steel.

See pic

Paul G

Rescued attachment tools-001s.jpg

SixedUp - 2/4/06 at 07:15 PM

I really, really, really need to learn to weld.

I was looking at the price of sheet metal folders a while back and thinking they looked like daylight robbery ... whereas this looks better quality,

is probably better made, and probably cost a fraction of the price.

Cheers

Richard

NigeEss - 2/4/06 at 08:19 PM

Curiously enough I found this earlier whilst looking for plans for a 3 phase converter.

Linky

wilkingj - 2/4/06 at 08:26 PM

Paul, you should draw that up and flog the plans... Its a beast.

Geoff

907 - 2/4/06 at 09:05 PM

quote:

Originally posted by wilkingj

Paul, you should draw that up and flog the plans... Its a beast.

Geoff

IMHO

The whole idea of building something like this is that you make it

out of what you can get hold of.

The channel could be angle. The bar could be as well.

NigeEss's link shows just this.

The moment you follow plans you tie yourself down.

As they say in engineering, "the drawings only a guide".

That little lot cost £10 by the way.

Paul G

Schrodinger - 3/4/06 at 11:51 AM

Thanks for the help gents

NS Dev - 3/4/06 at 01:18 PM

quote:

Originally posted by 907

I made one from offcuts from work.

A length of channel, length of bar, codged up hinges for the ends, and box for legs & handles.

A clamping bar on the top held on with G cramps.

It'll bend 1.2 stainless, a metre long, or 1.5 mild steel.

See pic

Paul G

I love Paul's usual understated attitude here!!!!

"codged up hinges"

lol, they don't look codged up to me mate!!!!!

Nice job (as usual and always!!)

cheers

Nat

907 - 3/4/06 at 04:04 PM

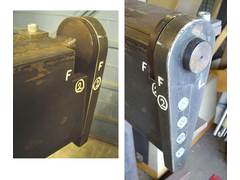

But as you can see Nat....

I just HATE painting!

The only important bit is that the centre of the hinge must be spot on

the corner of the channel, so as to give a nice sharp bend.

Paul G

NS Dev - 3/4/06 at 10:31 PM

so do I!!!

My engine crane is a disgrace!!!

Thats it on the hinges though, a swine to geat absolutely dead on!

You've inspired me to get off my arse and gather/purchase the necessary materials at work to make a proper one of these folders now though!

Doubt that will see any paint either!

cheers

Nat

907 - 4/4/06 at 05:02 PM

quote:

Originally posted by NS Dev

so do I!!!

My engine crane is a disgrace!!!

Thats it on the hinges though, a swine to geat absolutely dead on!

You've inspired me to get off my arse and gather/purchase the necessary materials at work to make a proper one of these folders now though!

Doubt that will see any paint either!

cheers

Nat

Wow, I've never "inspired" anyone before.

Below is a close up, or as close as I'm willing to go,  of the hinges.

of the hinges.

I turned the pins with a badly centred tool so it left a spike in the centre of the face to be welded to the channel.

This spike was then used to line up the hinge with the channel. A fluke really.

The square block on the top of the bed is a thickness stop for the top clamp bar.

Drilled off centre, another fluke, it can be turned round for different thickness sheet.

Paul G

Rescued attachment folder-hinge-s.jpg

NS Dev - 4/4/06 at 11:24 PM

are those hinge plates flame cut or milled? look flame cut but hard to tell (very neat if they are!)

Need to get one of the chaps at work on the night shift to make em up on the miller for me, 2 lumps of square bar just won't look neat enough!

907 - 4/4/06 at 11:51 PM

Oxy/act profile cutter.

I need longer lunch breaks at work. Half an hour is just not enough.

Paul G