Hi All,

I've got a hobby compressor (2HP, 25L) which is not too bad for most of what I do but my whizzy new die grinder makes it run out of puff very

quickly so I'm looking at external air tanks.

For safety it would want to be rated at 150psi but at this type of pressure you're looking at 75-80 Kg per square inch. I was looking at just

welding up a big box from 2mm mild steel with an angle frame and perhaps some internal bracing?

Any thoughs chaps?

Cheers,

Adam.

Id buy an extra tank. Theyr not alot of money.

If you made one and it blew itd make a mess.

There is no way a square pressure vessel would be safe even if reinforced.Why dont you use an old lorry air tank ,or a red propane bottle.The red

propanne gas bottles are tested to a sufficent pressure to be safe , I cant remember the exact test pressure but it is in the region of 24 bar. I have

an old propane gas tank from a transit van gas conversion for my compressor and run it at 100psi.

Paul

Ditto - dont attempt making one. We have loads of old propane bottles nearby...

I made a portable air supply for my daughter's air brush using a propane bottle. I charged it with my compressor using a tyre inflator. It could easily be used as an additional volume, but I didn't need to - 160l tank

OK, square box = shed blown up (Not my shed so that wouldn't go down to well). I guess the next question is where the blazes do I get a propane

bottle or lorry tank from in SE Essex for as little money as possible???

Cheers Gents.

I once built one using a lorry brake tank. I was warned not to use propane bottle as they were only rated at 90psi. A bigger tank isn't going to raise your output, it will just give you more storage. You need a bigger tank and pump, meaning a bigger compressor or swap your die grinder for an electric one. I got one from Aldi for £11.99 with a flexible shaft and a bench mount all in a plastic case. It doesn't ice up or slow down and it uses less power than a compressor and is a lot quieter. My air grinder stays in its box now.

I went down my parents 2 weeks ago to help clean the garden,We took ten of them to the locall tip who already had atleast 20 more.Have a word at your

locall tip and see if you can pick one up..You can often get big tanks on ebay used for air dryers ect and dead compressors they often fetch bugger

all due to the hassle of collection...

I had your dilema and welded the brakets on to a bigger tank,it worked for years but I never trusted it....I should have just hooked up the extra

tank........

Our local rubbish tip had several propane bottles the other day

The service pressure of a propane tank is in the region of 150psi and test pressre on my tank is marked as 24bar , the blue butane cylinders are rated

at a lower pressure however as butane has a much lower vapour presure.

My Compressor is a converted industrial freezer pump and not very high output , it will run a die grinder for a while as the tank provides a good

reserve and die grinder use tends to be intermittent .

I also have one of the aldi electric grinders and it is very good but not heavy enough duty for some jobs .

If using a cylinder it is best to just tee it into your existing set up , dont be tempted to weld to it.

Paul.

quote:

Originally posted by Peteff

. I was warned not to use propane bottle as they were only rated at 90psi. A bigger tank isn't going to raise your output, it will just give you more storage. You need a bigger tank and pump, meaning a bigger compressor or swap your die grinder for an electric one. I got one from Aldi for £11.99 with a flexible shaft and a bench mount all in a plastic case. It doesn't ice up or slow down and it uses less power than a compressor and is a lot quieter. My air grinder stays in its box now.

Just look for the gypsy camp, they allways leave propane cylinders everywhere.

This was the guy at the scrapyard where they use the cylinders for burning. He gave me the lorry tank so he wasn't after my money  . I have a

3hp 50ltr sip now but that still runs a lot if you use the die grinder. If you increase your storage massively with the same pump you will be

frustrated waiting for it to get up to pressure, running two compressors into the tank would be another option.

. I have a

3hp 50ltr sip now but that still runs a lot if you use the die grinder. If you increase your storage massively with the same pump you will be

frustrated waiting for it to get up to pressure, running two compressors into the tank would be another option.

Thank's for the suggestions chaps. I'll see if I can locate an orange tank somewhere. Unfortunately our local tip was long ago replaced with a recycling centre but I'll give them a go. I know I really need to up the CFM for big boys air tools but I can afford to be more patient but can't afford to buy another compressor!

Running 2 compressors works well

I've had old gas cylinders up to 300psi and I'm still here!!!!

Lots of things will work as an air tank.

Old water heater(Non-leaking)

A section of pipe.

A coil of tubing or hose.

Gas bottles 1 or multiples.

Portable tire inflation tank

Like I said lots of things will work, just keep your eyes open to possibilities.

quote:

Originally posted by britishtrident

Running 2 compressors works well

I am using a propane fuel tank from a truck as my compressor tank- a freebe from the recyclers. I also use a 30lb propane tank as an airpig for

portable use.

Dale

local tips or "recycling centres" still have loads of them, plus plenty of C02 bottles which are useful too!!

quote:

Originally posted by 40inches

B&Q warehouse have a 1.5hp/6cfm compressor with a 6litre tank for £49

just thought id dig this up again to ask soldered copper pipe will take 150psi?

just thinking of hard plumbing my compressor to the garage as it will be moving out to a seperate shed to make more room in the garage so i was

thinking i could use 22mm copper pipe so it aslo expands the capacity as well!

any thoughts??

Cheers,

Russ.

Suspect soldered joints may be a bit dodgy but no doubt someone may know for sure but have you thought about usin the correct type of pipe with threaded connections . not to expensive and a correct size die would be cheap to hire . It's also possible to use flexible air pipe which is even easier to use than copper . Check your local garage equipment suppliers

pressure table, no guarantee of accuracy!

http://www.liangchew.com/prod01.htm

62 BAR for the tube itself!

[Edited on 15/7/05 by JoelP]

You could use transport refrigeration seamless copper piping it has a thicker sidewall and silver solder the joints. Don't know what the max pressure is but it's quite high as they pressure test them from a nitrogen cyl using a regulator. I could find out for you on monday if you need more info u2u me.

cheers for that people! looks like itll be ok from that link, guess i can just go ahead and try it, if the joints fail i gues i could just braze them

properly as it looks like the tube is well up to the job.

Cheers again.

Russ.

but the best would be silver solder.

IMHO

In 4th place, soft solder.

In 3rd place, silver solder.

In 2nd place, brazing. (brass)

But by far the easy option....

Nylon, with push in fittings.

It's whats used in industry to pipe up pneumatic rams etc.

I have a loop of this in the roof of the garage with plug in points in various places.

Paul G

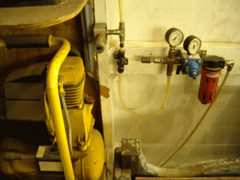

Rescued attachment air-com.gif

I was messing about in the garden yesterday using a compressor to pressurise a plastic coke bottle then let it go like a rocket - good fun.

The bottle had no problem coping with 100 psi. I have heard that they will take 1000psi. This suggests that connecting loads together would work as a

resevoir.

why not use compression fittings?

would that not be better if not slightly more expensive than using solder fittings?

let me know how you get on, as it's something i'd be interested in having a go at.

tom

Hi,

This is proper plastic push fit air line pipe.

https://secure.thorite.co.uk/Products_Snapline_tubing_239.html

Not much dearer that copper pipe. I think.

The plastic unions that go with it can be easily disconnected and re-used.

David

Copper done correctly for air lines requires a bit of thought and skill but can be very nice. I've plumbed complete shop air supplies with

1/2" hard copper pipe and soldered joints. I'm quite good at soldering. I learned to solder properly (in very expensive silver no less) at

12 from my plumber Dad and Granddad so had lots of practice and good teachers. I water tested those systems to 250 psi for 2 days with no leaks.

Normal running presure is about 150 psi in most shops here. The rated max presure for M type annealed 1/2 copper pipe is 420psi. at 100 degree F. The

joints soldered with Sb5 alloy (95-5 Tin-Antimony) are rated to 1090 psi at full penetration. Be warned though Alloy Sn50 solder ( 50-50 Tin-Lead) is

only rated to 200psi. Be very careful with the solder type if using copper for air lines. A few point to help out. 1. clean the pipe and fitteing to

perfection. 2. use the proper flux and solder 3. heat the fitting and let the solder flow toward the heat

If you can weld a car together you most surely can solder copper pipe.

[Edited on 21/7/05 by madman280]

Jon,

Carfull with them coke bottle experiments mate - you can put and eye out, knock off the neighbour cat or bust a gut laughing

[Edited on 21/7/05 by madman280]