see thread here

Cheers

Fred WB

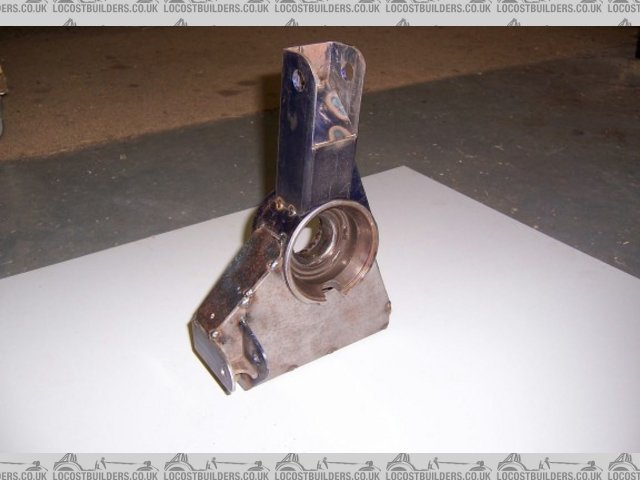

uprights

[Edited on 30/11/06 by Fred W B]

Bit more on ally verses steel uprights

see thread here

Cheers

Fred WB

uprights

[Edited on 30/11/06 by Fred W B]

that's a nice piece of work!

That steel one looks fantastic.

Yea, makes my effort look a bit sick

Cheers

Fred W B

upright tack

upright parts

[Edited on 30/11/06 by Fred W B]

Not too shabby though Fred, it just makes yours look over engineered.

I'm off down to the lathe now!

Nice one Fred. The wider bottom mounting points are always better for distributing load, and it would be nice to find out the wieght of all 3 uprights.

On thing worth bearing in mind when considering the ally versus steel, is that the ally one on the left was designed many years ago to go onto the cars that probably were headed for road use. Hence they wont be as close to the limit as the steel ones, which he has clearly made to be as extreme as possible - when the steel one was made the whole aim was probably to be lighter than the ally originals. In fact the steel one looks a lot better engineered. Hence not quite a fair comparison. I wonder how much he could shave off the weight of the ally one if he put his mind to it?

The reason for those holes in the linked design is air cooling.

Use a high temperature grease or let conduction do the job, not air cooling.

Air cooling an outer race of a bearing can cause the bearing to pinch the balls or rollers leading to a much shorter life.

As the housing is a fairly beefy bit of steel (same expansion coefficient) and the holes are not that big they've probably got away with it.

quote:

Originally posted by cymtriks

The reason for those holes in the linked design is air cooling.

Use a high temperature grease or let conduction do the job, not air cooling.

Air cooling an outer race of a bearing can cause the bearing to pinch the balls or rollers leading to a much shorter life.

As the housing is a fairly beefy bit of steel (same expansion coefficient) and the holes are not that big they've probably got away with it.

are the holes not there to allow for better cooling (not sure how much better mind) of the brake rotors?

I thought the holes were an easy to manufacture way of creating a web to bind the hubcarrier to the upright.

A bit like this design but simpler to make...

quote:

Originally posted by Alan B

Agreed, it looks cool...but do the holes serve any real purpose?...I await being convinced.

Very true. Without the holes, that would be a pretty hefty chunk of solid steel.

It's probably another way of keeping the heat effected zone from welding away from the carefully machined bore for the bearings.

Update on this upright + weight confirmation at 10 lbs, 4.5 kg

Here

Cheers

Fred W B

[Edited on 6/3/07 by Fred W B]

It looked like weight reduction to me rather than cooling, but cymtriks knows what he's talking about and I don't, generally speaking.

wouldn't you machine something like that after welding?