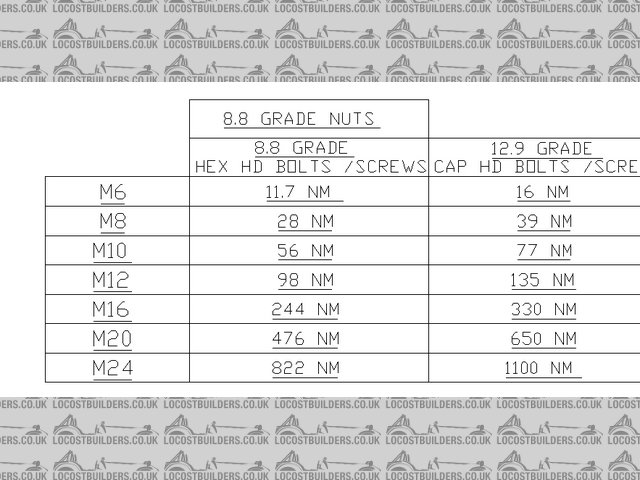

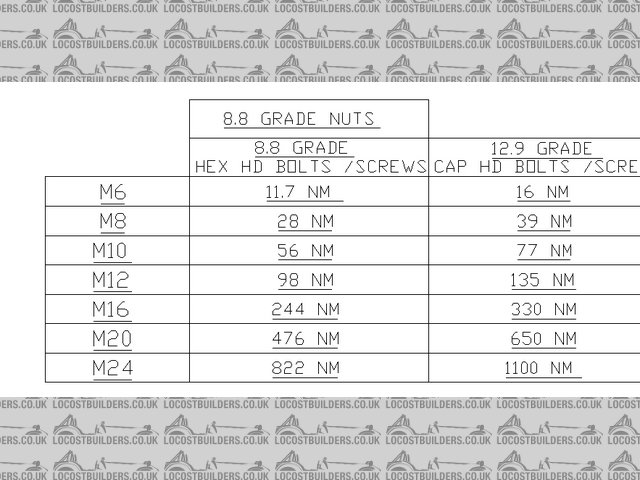

Torque Settings

HTH,

Rich.

hi all,

can anyone tell me the tightening torque for the 3/4" wishbone to chassis bolts?.

thanks

Ray

Strip the thread and back it off three turns!

Just kidding.........sorry!

Doesn't it say somewhere in the'book'?

Anyway how can you torque them up properly if you're using locknuts, which I believe is what you're meant to use? Well it's what I used

anyway....Nylocs (no it's not a swear word!)

Anybody have any comments?

[Edited on 12/4/05 by jonbeedle]

You never mentioned the thread pitch or grade of bolt. I'd avod any lubrication. Perhaps this web site might be of some

help.http://raskcycle.com/techtip/webdoc14.html

As well I would be inclined to use a drop or two of thread locker like the loctite blue med strength one.

The maximum torque setting for any fastener is dependant on its diameter, length, thread designation and material composition. Torque settings are

quite critical and seldom as high as people imagine. A lot of people over-stress smaller bolts (up to 12mm)just using a ratchet. If in doubt, ask the

supplier or manufacturer for exact figures.

For the wishbones, I wouldn't worry about finite torque settings as the fasteners are in shear, not tension. As long as the crush tubes are

pinched tight and the nuts are locked on, then you'll be OK.

I would also recommend using some form of wet or dry assembly lubrication. The aerosol assembly lubes are easy to apply with little mess and wastage.

Don't just slap on Coppaslip or any old anti-sieze paste; they're really messy and attract dirt.

And now for the easy answer! Courtesy of MK-Ninja.....

Torque Settings

HTH,

Rich.

I was under the impression that copper slip/grease did not attract dust/dirt like othert grease do. Which is why its used for a variaty of aplications including breaks.

quote:

Originally posted by clbarclay

I was under the impression that copper slip/grease did not attract dust/dirt like othert grease do. Which is why its used for a variaty of aplications including breaks.