Can someone tell me how I can split the stub axle from the driveshaft of a Sierra 4x4 rear end when they are OFF the car!

I've got to

remove the devils torx bolts, but how can I stop the whole axle turning?

I've got to

remove the devils torx bolts, but how can I stop the whole axle turning?

Cheers

Hi all,

Can someone tell me how I can split the stub axle from the driveshaft of a Sierra 4x4 rear end when they are OFF the car!  I've got to

remove the devils torx bolts, but how can I stop the whole axle turning?

I've got to

remove the devils torx bolts, but how can I stop the whole axle turning?

Cheers

Grind off the torx bolts and replace them.

They're 57p each from Ford or 2p each from somewhere decent. The halfmoon washer thingies are 75p each from Ford so grind carefully!

I'm pretty sure you'll need the hub nut off too to extract the whole thing from the trailing arms. Get an air gun...

Or a really long breaker bar. You'll have to clamp it best you can in a big vice.

HTH,

James

easy way 1, air gun.

easy way 2, good pair of mole grips & lever in studs.

Enjoy.

they are always a complete pain!! Snap-On won't even guarantee the torx bit for this job!!

I just grind em off (the heads of them), and replace with hex-socket capheads. You don't need the washer thingys (as I have said many times on

here, I have gone without them for a lot of races now with no worries at all)

I removed the hub nuts and withdrew the stub axles from the hubs. I had to use a puller as the splines were quite stiff.

For the allen bolts that I couldn't get out of the diff end with Snap On bits I welded a larger, (19mm I think) bolt onto and they gave up

easily.

Mick

I've got it sat in the electrolysis bath all in one piece (with the rubber bit out of the water BTW), I'll see what they come out like.

I think I'll have to split them anyway to machine the ABS teeth of in a lathe, I don't fancy doing that with the driveshaft attached!

I've just done a lower balljoint in the electrolysis bath complete with rubber cover on.

Didn't affect it at all, in fact just cleaned muck off.

You should be safe letting the rubber into liquid.

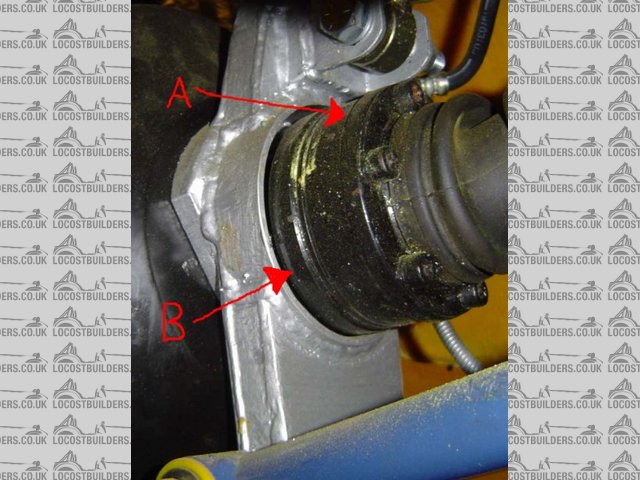

Where does it actually split? Is it at A?

Ignore B thats for something else...

Rescued attachment split line.jpg

close but no cigar,its the grove betwen a and b

So that would be "C" then!

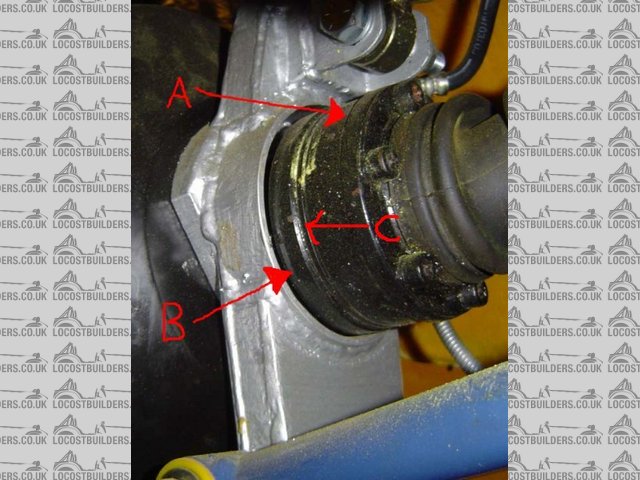

Can anyone see a problem if I remove a little bit of material from the area marked "B" to fit the upright?

Cheers

Rescued attachment split line 2.jpg

In a word NO!Just take it off as evenly as possible mainly to make it neat and balance ok.

A lot of us have had to remove the ABS ring from the same area in order to fit the shaft into the hub carrier,did mine in the lathe no probs.

I replaced all my Torx bolts with zinc Hex capheads(10.9) and spring washers, as I really get pissed off with Torx bolts.

I've got a few hundred quids worth of Snap on torx socket bits and torx keys and the bloody things are just a pain whatever you use!

I take it you used a few carbide inserts up then in the lathe!?

The abs teeth are nitrided!

The abs teeth are nitrided!

Mine are really soft, (oo err), no problem to file off.

Unless corrosion has eaten away the nitriding.

Mick

Never chipped a tip,mine were definately not nitrided.

very strange, mine were, nothing (saw, carbide lathe tools etc) would touch them!!

The XR4x4 driveshafts I had were the same, carbide lathe tools just made lots of sparks and smoke, no cutting, they were bloody hard too!

Something strange going on because I have seen loads cut and welded!!

Mine came off easy too in the lathe

also when dismantling the hubs myself and conrod just just cut the torx heads off with a 0.9mm cutting disc in a 4.5" grinder no problem,as james

said the bolts are not expensive from fords although you do need 24 of them.

[Edited on 2/1/05 by bob]

This is what I did. It worked a treat for holding the axle, and cost nowt but a bit of time and a scrap disc.

Shaft Holder