if you can help, please do.

thanks

Hi,

does anyone have an OBP floor mount pedal box running a cable clutch on a type 9. Just got a few questions to ask.

Just want to know if the clutch is ok to operate with this set up??

And can anyone help me out with some measurements? need to be sure it will fit in my footwell.

I really need to know how deep the pedalbox is but from the pedal face at its rest position to the very back of the mounting base. Is poss please.

Only ask as iu know it ownt fit in the bottom of my footwell, but i dont think it needs to go at the end anyway as i cant reach it. With this

measurement i can be sure it will squeeze in.

I know it may be a pain but i hope someone could help please.

thanks

I don't have an OBP pedal box but I do have an old Luego item in my car with a cable clutch which works fine . I did make up an outer cable stop to fit against the outer bulk head to get the cable to run at the angle I wanted (Big washer and a piece of thick walled pipe , 5minutes work) If no one is able to help with the OBP parts I may be able to help

been reading, isn;t the leugo one made by the same person.

is it the same size? 230mm wide?

thanks for the reply

is anyone able to tell me the depth from the pedal faces with the pedals in the rest position please???

thanks again

Will try to measure but will be later today at the earliest.

that would be ace.

many thanks for helping out

someone on here must run OBP box, i have read loads about them on here.

if you can help, please do.

thanks

Hi

I have modified quite a few to get them to actualy work correctly in a car once installed. It's things like having to re machine the clutch

pedal pivot so the cable runs through centrally and not at an angle which breaks the cable regularly.

Re bushing the pedal pivot bars which are made of mild steel. cutting the bias bar down in length so it dose not collide with the clutch pivot and

restrict the movement to the inner master cylinder. And the final PITA modifying the pedal tops so that you can get your feet into the right position.

Or alternatively modify the push rods on the master cyls to achieve simalar effect. And the joke one is the lightweight version that can be flexed by

hand.

Must admit i have never measured one up dimensionally. Usually to busy modifying them to work or throwing them in the bin.

Not exactly helpful but thats my experiences with the product. And the worst of it is the car i am racing next year has one fitted by the previous

owner.

Cheers Matt

quote:

Originally posted by procomp

Hi

And the final PITA modifying the pedal tops so that you can get your feet into the right position. Or alternatively modify the push rods on the master cyls to achieve simalar effect.

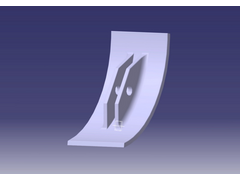

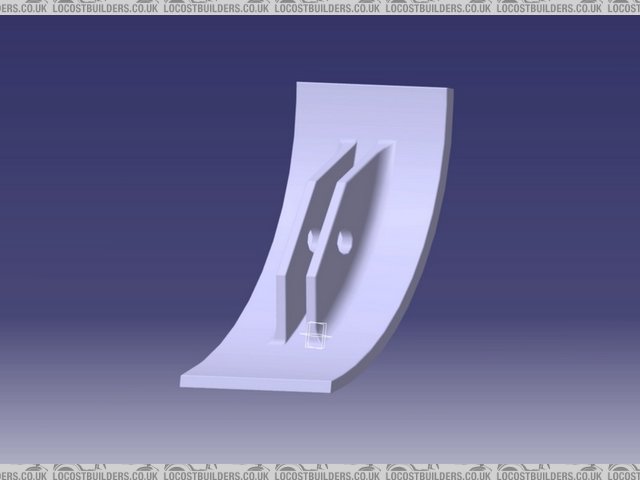

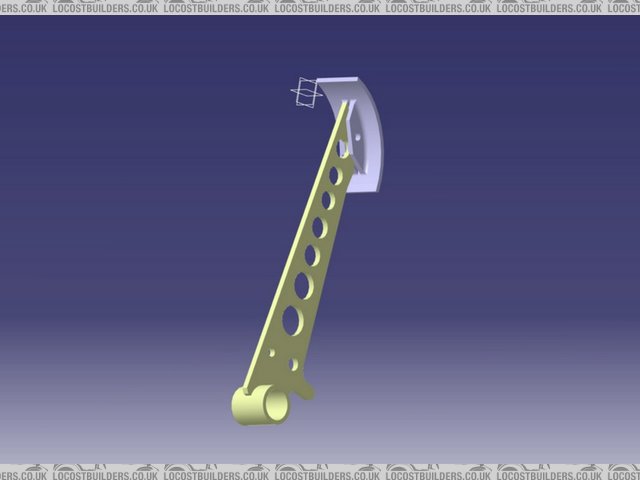

And here is the final pedal-pad assembly. I think that this configuration will add a bit of versatility for the drivers as there will be no need to

modify the MC rod or incline the pedal and bring it closer or further away from the firewall.

Rescued attachment new pedal.jpg

Hi

Unless i am being a bit thick i am seeing no adjustment for forward and back movement on that pedal. Just a bolt on pad section with no adjustment.

Surly what you want is a screw adjustment to move the pedal pad forwards and back to suit with about 50mm of adjustment available.

And also a bit more quality to the finished product. There's weld spatter still evident on the pedals here and what is going on with the outer

pivot tubes not being machined. Looks like they have been hacksawed off and left at that.

Image deleted by owner

Cheers Matt

[Edited on 7/1/09 by procomp]

quote:

Originally posted by procomp

Hi

Unless i am being a bit thick i am seeing no adjustment for forward and back movement on that pedal. Just a bolt on pad section with no adjustment.

Surly what you want is a screw adjustment to move the pedal pad forwards and back to suit with about 50mm of adjustment available.

And also a bit more quality to the finished product. There's weld spatter still evident on the pedals here and what is going on with the outer pivot tubes not being machined. Looks like they have been hacksawed off and left at that.

Cheers Matt

[Edited on 7/1/09 by procomp]

matt

thanks very much for the comments, not sure i would like one of them now.

cheers again