Opinions sought on electric reverse placement

JekRankin - 18/7/11 at 10:53 AM

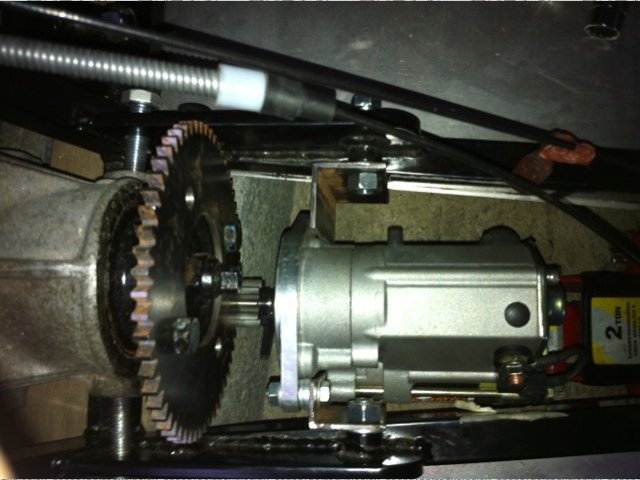

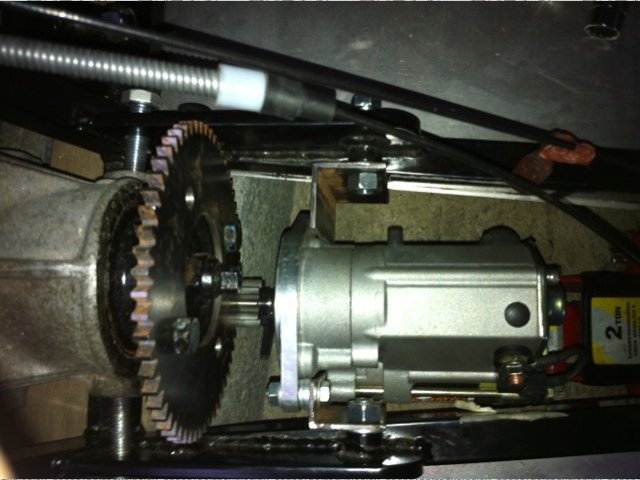

Iíve made a start on my electric reverse mounts and would like some opinions on my concept before I do any more fabricating.

If I place the motor on the underside of the diff gear, I can make use of two of the harness mounting holes (which Iím not using initially as Iím

fitting 4-point harnesses). This is convenient because it avoids me having to drill or weld the chassis more than necessary, and the bracketry is nice

and simple.

The drawback with this arrangement is that the starter motor hangs down beneath the chassis by about three inches. The wiring terminals on the motor

will still be higher than the bottom chassis rails, so the wiring isnít too exposed, and the motor itself is only sitting half an inch lower than the

bottom of the sump.

I canít think of anything in the manual which would prohibit this arrangement, but for some reason I still think that the IVA inspector may not like

it. Before I go ahead and add some stiffening to my two brackets and a further rear mount for the motor, what is everyone's opinion on this

design's suitability for IVA?

Post IVA, I might swap the assembly with a much lighter solution, made of air. :-)

Thanks,

Jek

Description

Description

Description

[Edited on 18/7/11 by JekRankin]

Davegtst - 18/7/11 at 12:07 PM

Mine is fitted in the same place and hangs below the floor level too although i have a different starter motor. I have made a guard/cover out of

quite thick aluminium that covers it up completly so hopefully Mr IVA man will be happy.

phoenix70 - 18/7/11 at 12:07 PM

might do for the IVA, but I wouldn't drive on our roads with that stick out under the car. Normally the rear suspension is softer than the front

so I would think there is a good chance of grounding the over a bump.

T66 - 18/7/11 at 12:27 PM

I would be more concerned grounding that at speed, it could cause you to lose control. And at the very least trash your motor.

That imho could be a safety issue the iva inspector would pick you up on.

From the general construction section - Point No4 I see as your reverse motor?

1.

All aspects of the design and construction of the vehicle must be such that no Immediate danger is caused or likely to be caused to any person in the

vehicle or to other road users (see note 1).

4.

A transmission/braking component which rotates during vehicle operation, electrical component, steering or suspension component, wheel or tyre must

not foul on another component, or be likely to foul under normal operating conditions.

adithorp - 18/7/11 at 12:32 PM

Thats going to last about 5 min's before you smash it clean off on the road! It's well in front of the axle line so will hit speed humps

before the wheels start to go up them.

I've only got 5" clearance there on my Fury. It's is running pretty low and but I'd be supprised if you had much more.

Doctor Derek Doctors - 18/7/11 at 12:36 PM

Why not put it on the engine end?

My ring gear is on the adaptor plate at the engine end and the starter has plenty of room.

As said where you are placing it is asking for a smashing, if you straddle a curb on a track day there will be nothing left of it.

RACER101 - 18/7/11 at 01:00 PM

Hello,

I assume that you are fitting this to a Fisher Fury?

If so why not position the reverse motor in the transmission tunnel but above the diff instead of below?

I did this succesfully on a racing Fury and, whilst it was a tight-ish squeeze, it worked fine and the ali top cover on the transmission cover

didn't require any modification. Even if the reverse motor stood a little above the trans tunnel top rails it wouldnt be too hard to fabricate

suitable cover plate.

I did choose a relatively small motor (Honda Blackbird starter motor I think).

The original reverse starter was located at the engine engine end but (with a Busa engine) it made the mouth of the transmission tunnel horribly

congested with clutch release, prop shaft, wiring, fuel pipes, gear lever and reverse starter clutter all fighting for space.

Good luck

John

JekRankin - 18/7/11 at 01:08 PM

Thanks for all the comments.

Iím only planning on having the reverse to get me through IVA, after which Iím planning to remove it, so Iím not worried about it taking a battering

from speed bumps and kerbs.

The Sierra diff flange PCD is different from that of my prop adaptor, so fitting it at the engine end wouldnít be an option unless I got the gear

modified. I could fit the motor above the diff flange, but the bracketry needed for this would be more complex, and Iíd also have brake/fuel lines,

the wiring loom and the handbrake cable in the way.

For IVA Iíd imagine Iíll have the suspension jacked up fully (to increase the headlamp height) so Iím guessing I could have around 4 inches clearance

under the motor.

T66, I take your points on the General Construction section though. Iíd thought item 1. may have been a sticking point, but I hadnít really considered

item 4. All the physically rotating parts of the assembly are above the lowest chassis rail, but the motor housing is exposed I guess.

[Edited on 18/7/11 by JekRankin]

JekRankin - 18/7/11 at 01:13 PM

Hi John,

You are correct, its a Fisher Fury. I think that placing it above the tunnel, whilst a bit more complicated, is my second option if this one looks

likely to fail IVA. My car has the 'live axle' transmission tunnel where the top tubes go all the way up to meet the boot floor. This gives

me plenty of vertical space, but it means the mounts for the motor could be quite long and flexy. I'll take another look!

Jek

[Edited on 18/7/11 by JekRankin]

adithorp - 18/7/11 at 01:27 PM

I'd also be worried as to whether it'd clear the ground when they put it in the brake rollers. Can you not make up mountings to come off

your diff mountings?

JekRankin - 18/7/11 at 01:53 PM

Hmmm, that's a possilbility, I might be able to use the top diff mount to save me drilling holes when mounting the motor from above.

I liked the idea of mounting the motor underneath because it was really simple to implement, but its maybe not practical enough, even just for IVA.

Jek