Ali chassis on Ebay

flak monkey - 24/5/05 at 08:48 PM

Spotted this today: (Yes I know its Marc from MNR selling it  )

)

http://cgi.ebay.co.uk/ws/eBayISAPI.dll?ViewItem&category=100921&item=4551975923&rd=1

Is this one of those made by MK a while back? ISTR discussion about it on several occasions.

Might be ok for a race/sprint car thats going to be checked regularly, wouldnt use it on the road though....

David

nick205 - 24/5/05 at 09:34 PM

The description refers to it as a Formula 27 chassis. Either way I agree about using it on the road

marc n - 25/5/05 at 07:23 AM

yep chassis defintely f27 38mm round tubular durol chassis, looks pretty impressive

think the mk one was done in inch by inch box in standard alloy

best regards

marc

Triton - 25/5/05 at 07:48 AM

Not convinced an ali space frame is such a good idea....one shunt and it's a goner

JAG - 25/5/05 at 08:16 AM

One word - FATIGUE - aluminium will always fatigue and crack eventually can't be avoided.

It works OK in aircraft because most parts are 'lifed' in hours and replaced/scrapped after that time expires.

[Edited on 25/5/05 by JAG]

NS Dev - 25/5/05 at 11:17 AM

There are a number of offroad racers that lead much harder fatigue lives than a "second" road car ever will and have tubular alloy

spaceframe chassis.

An aeroplane's fuselage and airframe are not routinely replaced (don't know whether they are lifed but some 747's have been around a

long time if they are!)

I know about the MK ally chassis but as was said, that was a replica of a steel one!!!!! You have to tailor the design to suit the material, look at

an F1 car or mountain bike FFS!!!!!!!!!!!!!

Maybe thinking before answering would be good.

flak monkey - 25/5/05 at 11:40 AM

quote:

Originally posted by marc n

yep chassis defintely f27 38mm round tubular durol chassis, looks pretty impressive

think the mk one was done in inch by inch box in standard alloy

best regards

marc

Ahh, I wasnt aware of the difference between the F27 and locost chassis. It sounds as if the ali problems have been addressed and dealt with by using

the larger, stiffer tubing. It is a good buy at the price its sitting at at the moment.

The MK ali chassis wasnt meant to be used on road, and would be pretty useless as discussed before.

There are plenty of ali chassis cars (Elise for one) around. But most of them are not technically space frames (the Elise is a ladder frame) as it is

hard to get both the required strength and lightweight from an ali spaceframe, but relatively easy in a ladder frame due to the ability to use much

larger section tubing.

Any chance of some pics Marc, just out of interest more than anything.

I wasnt out to bring up the whole ali chassis debate again, as its been done to death. I was more curious than anything.

Cheers,

David

JAG - 25/5/05 at 12:20 PM

quote:

Maybe thinking before answering would be good

What an amazing lack of technical understanding you have

Over engineered Aluminium chassis will last a long time - but fatigue will get them in the end.

Aluminium has zero fatigue limit and will eventually fatigue no matter what the stress levels.

The 747, like all aircraft, has a recommended life and is regularly inspected for cracks and other fatigue damage.

Check your facts before spouting ill informed rubbish

Staple balls - 25/5/05 at 12:39 PM

JAG, do you have any accurate numbers to back up what you're saying, assuming say 6061 or 7005 T6 alu*, properly welded and treated?

and of course in various different configurations, compared with steel of many flavours.

I figure, if you want a decent fight about this crap, it may as well have some proof to it.

*picked out of the hat due to many years of mountain biking on frames made of these alloys

NS Dev - 25/5/05 at 12:46 PM

Just looking at the 6061 frame of my mountain bike that I came to work on this morning..........................better nip up the corridor and get the

dye penetrant aerosols out then!!

flak monkey - 25/5/05 at 12:46 PM

Steels between ~0.3 and 0.6% C show a fatigue limit if loading is loads are kept below a certain level. Which means cyclic loadings can go on forever

and it will never fail. Other steels do not have fatigue limits and will eventually break due to fatigue.

Most if not all ali's do not have a fatigue limit. And most will fail under much fewer cycles than steel.

(Materials courses can be handy sometimes  )

)

You can ignore HT on most chassis as when you weld you destroy the effects of any HT on the surrounding area. Of course if you can heat treat the

whole chassis without resulting in any distortion etc, then that problem wouldnt exist.

An ali chassis designed correctly will not have too many problems. But it will more than likely fail before a steel one due to fatigue.

David

Staple balls - 25/5/05 at 12:48 PM

quote:

Originally posted by NS Dev

Just looking at the 6061 frame of my mountain bike that I came to work on this morning..........................better nip up the corridor and get the

dye penetrant aerosols out then!!

pfft.

i spent the best part of 18 months landing 4-12' drops on a 7005 frame (a 21" planet x compo) oddly enough, it's still going

strong.

[Edited on 25/5/05 by Staple balls]

spunky - 25/5/05 at 12:56 PM

Taking my bike on the track on Friday, should I check for stress fractures before I go.......

John

Liam - 25/5/05 at 02:57 PM

Well maybe you ought too!

A seriously used ally downhill frame is generally considered to have a life of only 3-5 years. Not too sure about road racing ally frames, but

i'd have thought only about 10,000 miles. But then you'd have to be a serious racer to cycle a frame to the point of failure in that time

(assuming no bad crashes). You and me could probably keep a decent ally frame for many years, or at least as long as our commitment to ride lasts! I dirt jump on a 7005 frame and it feels bulletproof, but i'd always check it after a bad landing. My friend had a similar frame and broke a

headset bearing and the steerer tube on a bad landing without damaging the head tube/gussett at all. (But i'd still feel better with a steel or

Ti frame!)

I dirt jump on a 7005 frame and it feels bulletproof, but i'd always check it after a bad landing. My friend had a similar frame and broke a

headset bearing and the steerer tube on a bad landing without damaging the head tube/gussett at all. (But i'd still feel better with a steel or

Ti frame!)

As NS Dev says it is the design that is important. An ally aircraft fuselage can be designed to last 30+ years despite the material. Similarly for a

car chassis. The important thing is that an ally structure is stiff as any bending will fatigue the ally very fast.

As for an ally copy of a locost steel chassis - that is definately NOT stiff and will fail relatively quickly. That F27 frame seems much better but

who knows its fatigue life? Probably not even the designer.

And that's the problem with one off ally car chassis - unless the design is rigorously analysed and tested (which it mostly isn't) you never

know the date it will start falling apart around you on the road. This is NOT the case with aircraft and, to a slightly lesser extent, bike

frames.

Liam

[Edited on 25/5/05 by Liam]

Liam - 25/5/05 at 03:08 PM

Huh huh!!

Just read the add...

"One of only 3 ever made."

"Believed to be the only one left now."

Says it all!!

Liam

mookaloid - 25/5/05 at 03:26 PM

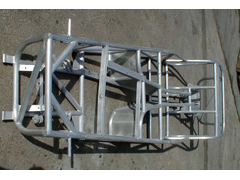

Just to say I have seen Marc's chassis and I have to say it looks very impressive. It is clearly designed with the material used in mind.

Could make a very interesting hill climb car, mmmmmmm.... now there's a thought!!

Cheers

Mark

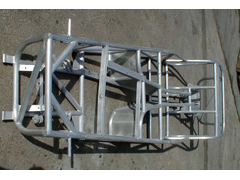

marc n - 25/5/05 at 03:29 PM

heres one

Rescued attachment alloy-chassis-1.jpg

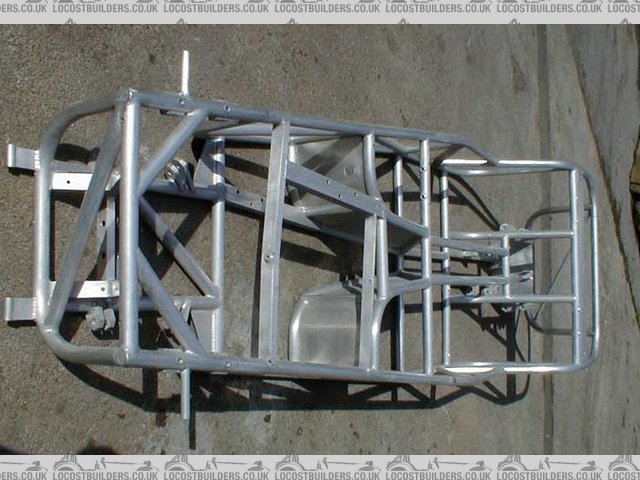

marc n - 25/5/05 at 03:30 PM

and another

Rescued attachment alloy-chassis-2.jpg

marc n - 25/5/05 at 03:31 PM

and another

Rescued attachment alloy-chassis-3.jpg

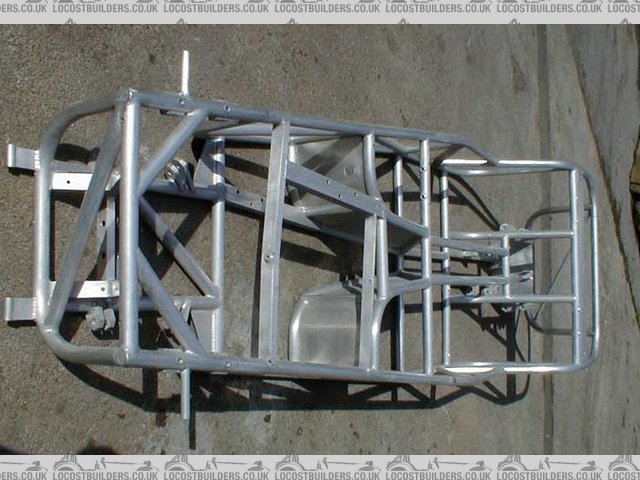

marc n - 25/5/05 at 03:31 PM

another

Rescued attachment alloy-chassis-4.jpg

marc n - 25/5/05 at 03:32 PM

finally

Rescued attachment alloy-chassis-5.jpg

ned - 25/5/05 at 03:39 PM

sure i've seen one of that design on ebay before, i remember the rear irs bulkhead plate arrangement..

Ned.

kb58 - 25/5/05 at 03:46 PM

I you bend a piece of steel back and forth slightly (staying in the non-elastic mode) you can do it a really long time. Now do the same with

aluminum. The very act of bending the aluminum causes it to work-harden, to get more and more brittle, finally reaching a point where it will crack

at the welds.

And AFAIK the Elise aluminum frame is *not* welded, either bonded or riveted... as are aircraft frames. The welding is what does it in.

Liam - 25/5/05 at 03:51 PM

quote:

Originally posted by mookaloid

Just to say I have seen Marc's chassis and I have to say it looks very impressive. It is clearly designed with the material used in

mind.

Yeah crikey, that's bitchin!! Nicely made. Wonder if its any lighter than a steel chassis though?

P.S. Got me a price for them brake lines yet marc? I wanna do the brakes soon.

marc n - 25/5/05 at 03:59 PM

gonna wade throught the emails tonight

flak monkey - 25/5/05 at 05:20 PM

quote:

Originally posted by kb58

And AFAIK the Elise aluminum frame is *not* welded, either bonded or riveted... as are aircraft frames. The welding is what does it in.

Yes the Elise chassis is bonded. My physics A-level teacher had something to do with the bonding method development.

Chassis looks good BTW Marc

mookaloid - 25/5/05 at 05:25 PM

quote:

Originally posted by Liam

quote:

Originally posted by mookaloid

Just to say I have seen Marc's chassis and I have to say it looks very impressive. It is clearly designed with the material used in

mind.

Yeah crikey, that's bitchin!! Nicely made. Wonder if its any lighter than a steel chassis though?

oh yes its definitely a whole lot lighter than a steel one - I would guess half the weight.

Now for a car that only does a few miles per year on hill climbs fatigue should not be a problem mmmmmmm... still thinking

JAD - 25/5/05 at 05:50 PM

7075 cannot be welded & 6061 requires heat treatment subsequent to welding (the welding process anneals/softens the alloy).

britishtrident - 25/5/05 at 06:02 PM

Any light alloy part has a finite life no matter how low the loading. Contrast steel at low loadings is considerd to have an infinite fatique life.

The added complication with welding aluminium is the heat treatment goes out the window and you have no real control of the metallurgy within the

weld not exactly ideal especially critical as welds tend to be at corner joints.

The frame in the picture is well engineered but I can't see it being lighter than a book Locost space frame although it could be a good bit

stiffer. 30 years back Porsche built alloy space fames for Le Mans as one race specials they were very worried about fatigue cracking to the extent

the presurised the tubes and fitted schrader valves so they could check for cracks at pits stops.

[Edited on 25/5/05 by britishtrident]

nick205 - 25/5/05 at 08:46 PM

Marc - any figures on the weight o the Ally chassis? I'd be very interested to see how it compares with a typical steel chassis.

Nick

marc n - 25/5/05 at 10:40 PM

if i get chance will weigh it tomorrow

Peteff - 25/5/05 at 10:58 PM

It would be a shame to cover that up with panelling, I'd have it like the Atom so everyone could see it.

kb58 - 25/5/05 at 11:57 PM

quote:

Originally posted by Peteff

It would be a shame to cover that up with panelling, I'd have it like the Atom so everyone could see it.

Except it would need to be corrosion protected just like any other metal. After painting it would look like any other chassis... in fact it would

"appear" heavier due to the larger tubes.

[Edited on 5/25/05 by kb58]

Rorty - 26/5/05 at 04:49 AM

quote:

Originally posted by britishtrident

30 years back Porsche built alloy space fames for Le Mans as one race specials they were very worried about fatigue cracking to the extent the

presurised the tubes and fitted schrader valves so they could check for cracks at pits stops.

Did anyone notice any helium tanks in their pits?

NS Dev - 26/5/05 at 07:09 AM

Really have had enough of this debacle now, but has anybody actually looked at a motorbike frame (well, most of them!)

They are designed for road miles and made using a welded aluminium structure (in most cases)

I know about all the arguments against aluminium, but you design around these.

I know of many arguments against wood but Marcos made some extremely good plywood racing cars!

Alloy/Nomex honeycomb is really a development of an alloy clad plywood composite, I don't doubt that that is where the idea came from anyway.

You cannot just take a statement like "welded aluminium cannot be used as it will fatigue crack" and apply it to any situation without

further qualification of the design.

I don't work in the aluminium industry, I work for a steel tubemaking company, but I do know that there are plenty of welded alloy structures in

heavily loaded, cyclic stressed applications, where cracking is not a problem at a sensible life.

As an aside, many steel structures are designed outside their "infinite" stress cycle range anyway. We did some research as part of a

project looking at loading shovels at College when I was doing my degree and it was surprising how many parts were loaded such that their life was not

infinite. (the main machine looked at had an estimated life at critical welds of 5300 hours approx, based on a simulated heavy duty work cycle, by my

calculation, which cunningly (or fortunately!!) was not too far short of the machine's overhaul interval anyway!)

MikeR - 27/5/05 at 12:40 AM

perhaps the concileratory statement (or three) is this .........

Ali can be used in a wide number of situations, but like all materials you have to take its strengths and weeknesses into consideration in the

design.

A general rule is that steel space frames can not be copied in Ali without the likelyhood of failure occuring very rapidly.

There is little proof that the formula 27 chassis has been designed for a life as long as the steel locost chassis. (can't help thinking it looks

like the robin hood 2b chassis with the round tube used!)

.......... does that cover it before all too many toys are thrown out of the pram?

u401768 - 27/5/05 at 12:00 PM

With out wanting to stir things up even me - welds on a steel chassis will fatigue, and fail long before any other part of the chassis. Even when

using MIG, the weld is contaminated, and also always comes out hard/brittle. So I would thing that given that the Ali chassis would have most likely

welded with TIG or similar, the differences in the fatigue rate of both types of chassis would not be that dissimilar. The Audi A8 chassis is welded,

and also made from Ali. I would thing that has a life expectancy of at least 15 years/200,000 miles, and has also been pointed out bikes have been

using this method for a long time with out problems. At the end there is not that much difference in the mechanical properties of the weakest section

(the welds) and it comes down to preference, experience and cost.

Peteff - 27/5/05 at 01:09 PM

I've not got anything on my bare aluminium panels and they seem to be standing up to the exposure alright. They don't get that much abuse

from the weather so neither would that.

kb58 - 27/5/05 at 01:57 PM

quote:

Originally posted by Peteff

I've not got anything on my bare aluminium panels and they seem to be standing up to the exposure alright. They don't get that much abuse

from the weather so neither would that.

Then you must have "alclad" coating which protects the aluminum. Bare aluminum corrodes by getting all chalky looking and pits.

flak monkey - 27/5/05 at 02:07 PM

Aluminium will only corrode if its in an environment where the AL2O3 layer is constantly damaged. Otherwise the oxide forms as soon as bare ali comes

into contact with oxygen (its a very very fast reaction), the oxide is a very hard ceramic and if left untouched a peice of bare ali outside will last

for years. Oxidised ali is the normal grey/white that you see. Before oxidation it is very shiney.

ned - 27/5/05 at 02:10 PM

so those who keep polishing their ally side panels are actually reducing the life of the panels?!!

MikeR - 27/5/05 at 04:35 PM

must remember that for when i find a woman and get married, sorry can't clean the car, i'm damaging it

now if i could just find a way to link that to dusting in the house ........

)

)