Lotus 24 / 25 / 49 drawings

ftaffy - 10/6/16 at 07:30 AM

Hey Guys,

A fairly generic question, i have a few that are around on the web but does anyone have

a) Any photos/drawings showing the assembly of the lotus 25/49 mono?

Be interested in the join of the inner and out skins around the cockpit - cannot get my head around that part to be honest and have alternatives in

mind to skip trying to do that as i can see it going pear shaped very quick.

The steel bulkheads - have a theory of how to do it but would like to see if its on the mark

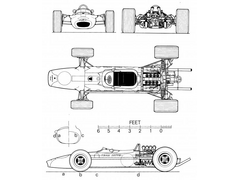

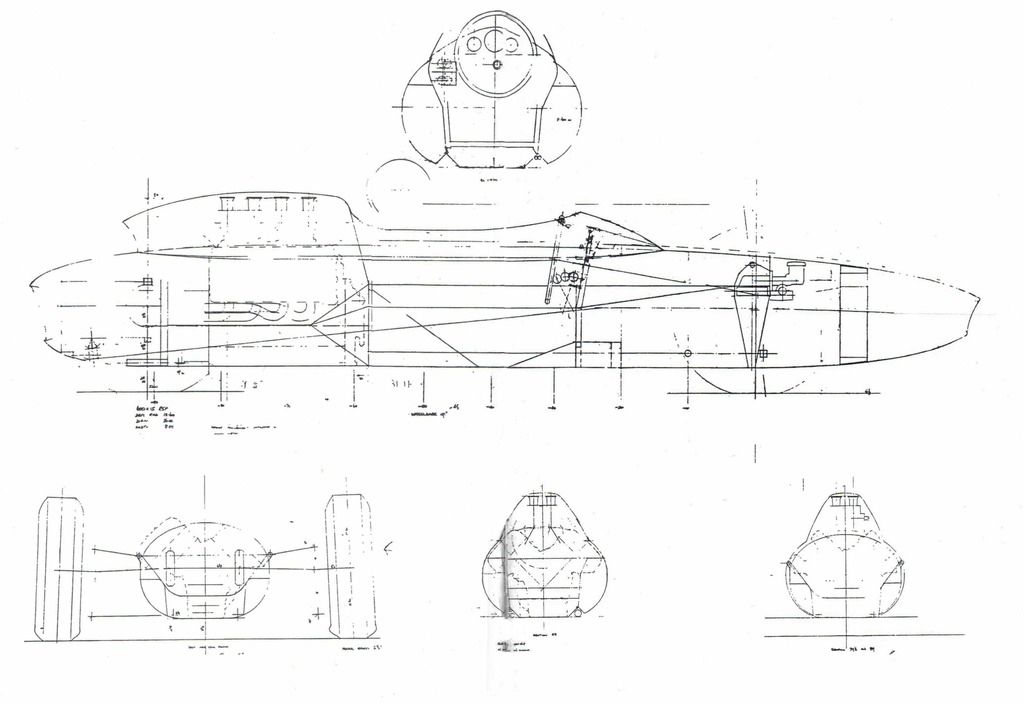

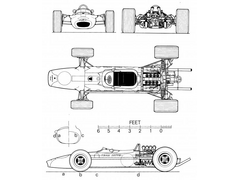

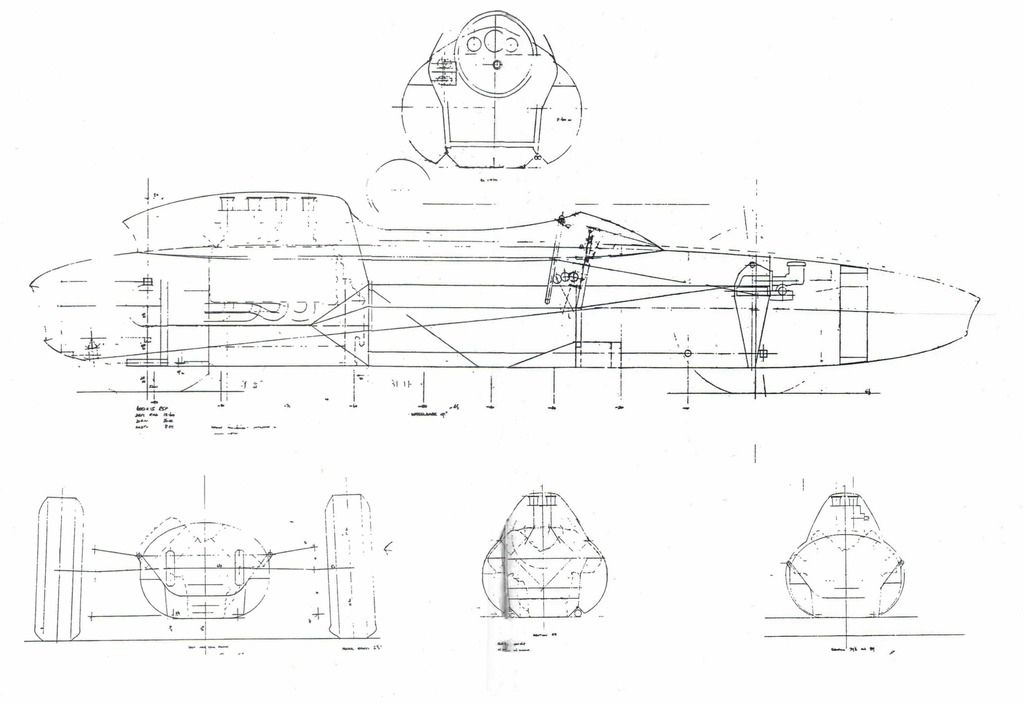

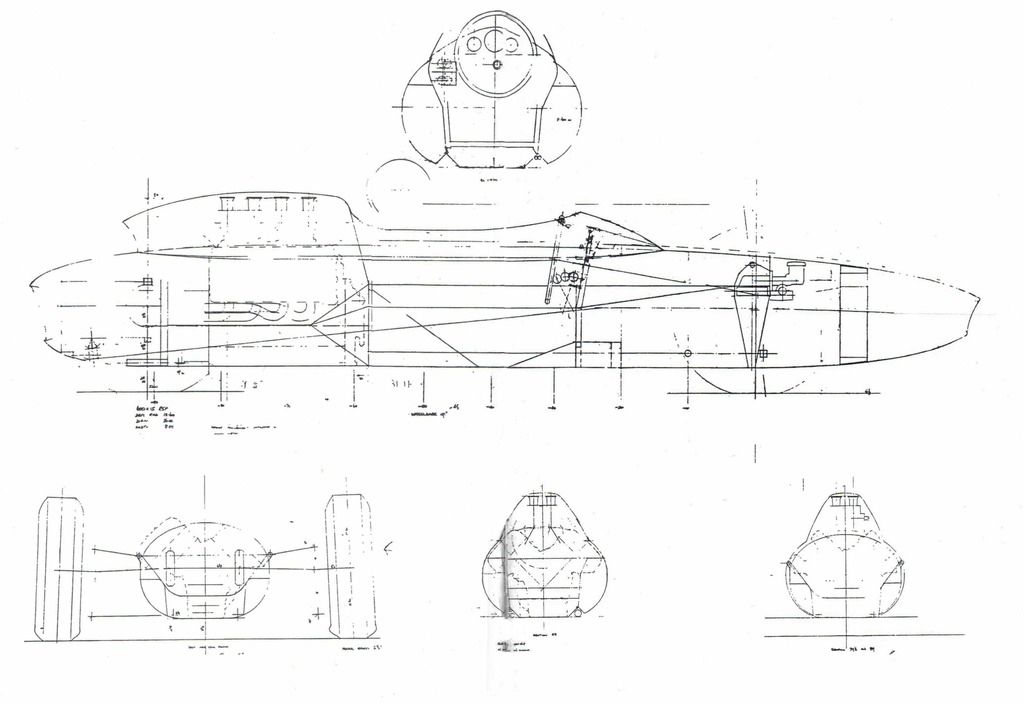

Also a better res of this one would help

Lotus chassis blueprint

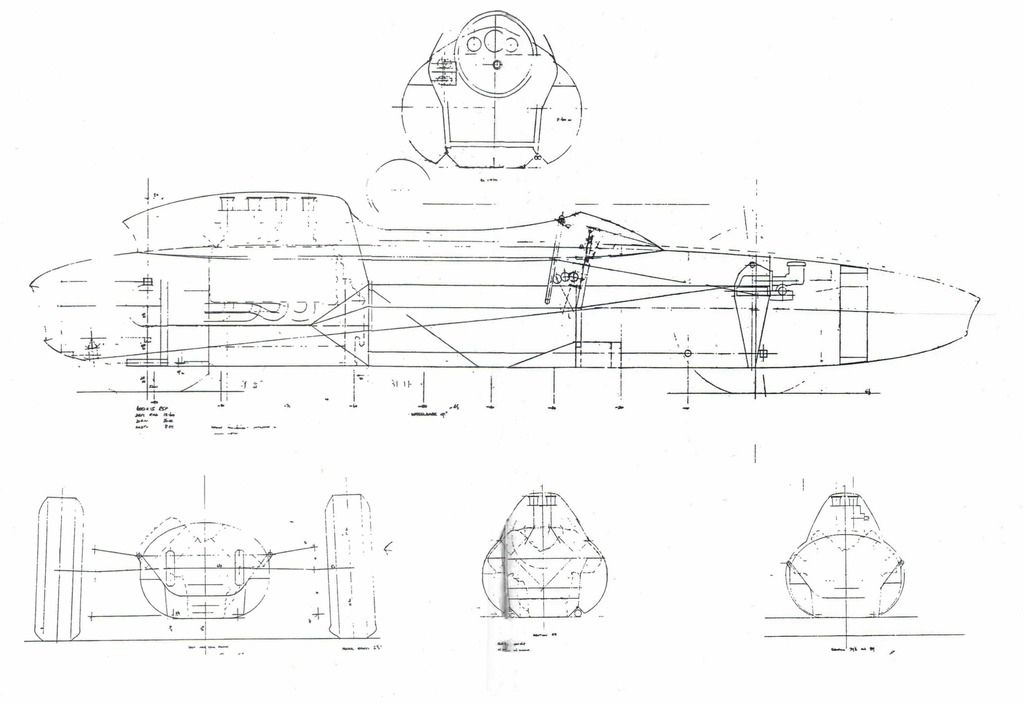

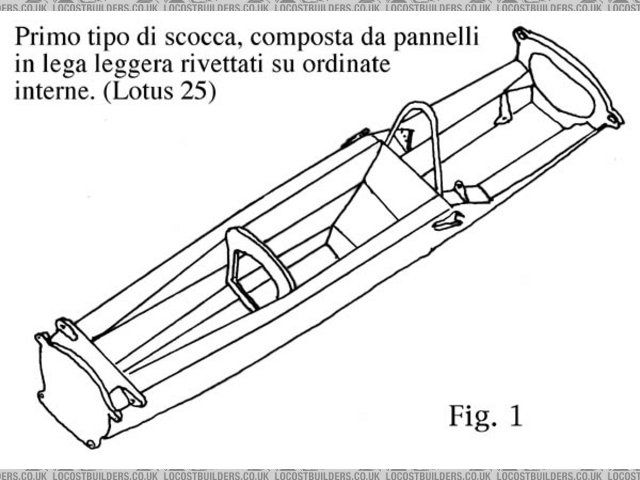

And this one of the 25

b) Drawings of the lotus 24 chassis?

Have the blue one which shows the chassis, which i can draw up the frame when combined with a series of photos i have come across but i will need to

guess some parts.

Have CAD models of the skins of both which is useful for trying to size things up but i will be stretching to fit a normal human so a redraw is in

order.

Not doing exact replica but obviously the more information the better

Thanks,

Taffy

[Edited on 10/6/16 by ftaffy]

[Edited on 10/6/16 by ftaffy]

Sam_68 - 10/6/16 at 09:36 AM

quote:

Originally posted by ftaffy

a) Any photos/drawings showing the assembly of the lotus 25/49 mono?

Be interested in the join of the inner and out skins around the cockpit - cannot get my head around that part to be honest

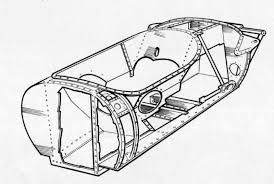

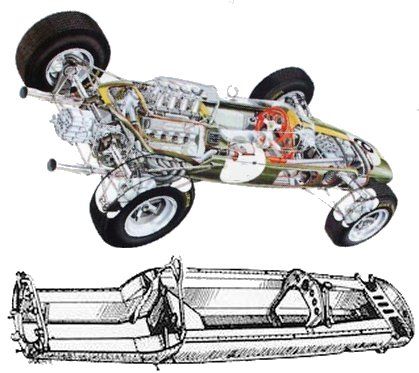

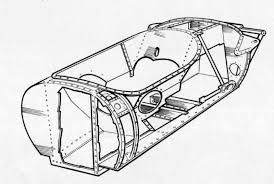

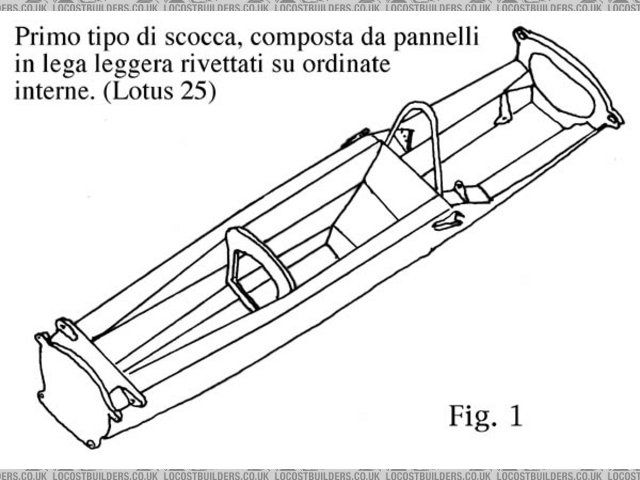

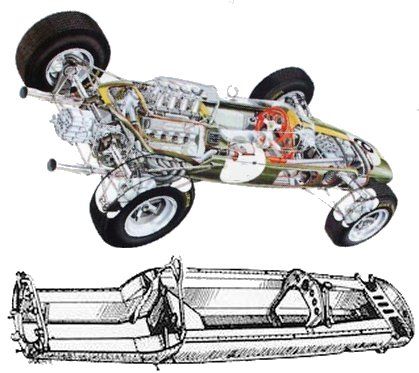

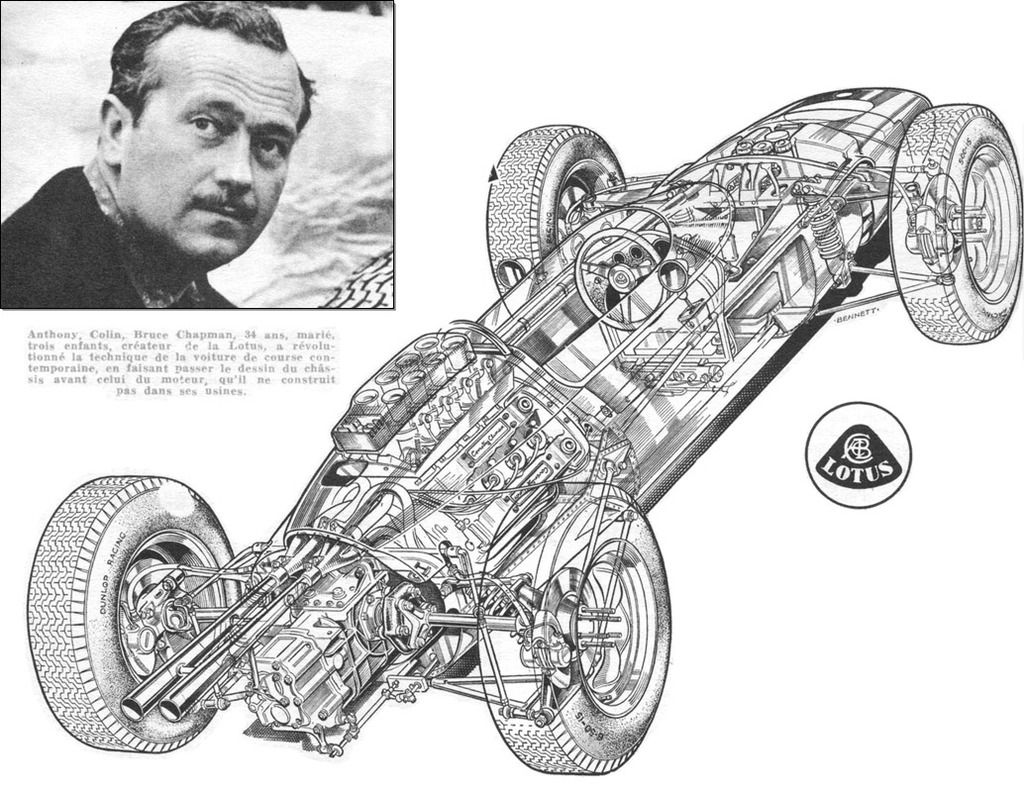

The 25 and 49 monocoques were quite different: the 25 was a simple 'bathtub', with an unstressed moulded GRP upper bodyshell sitting on top

of it, whereas the panels on the 49 extended up and round to form the upper cockpit, scuttle and rear bulkhead. And, of course, the key feature of the

49 was that it stopped at the rear bulkhead and used a stressed engine, whereas the 25 and other early monocoques projected the side torsion boxes

rearward on either side of the engine.

This is a 27, but it's fundamentally very similar to the 25 (except that the rear 'booms' on the 25 stepped down to clear the exhausts

on the V8) and is the best picture I've got that shows the area you're interested in:

This is a 25:

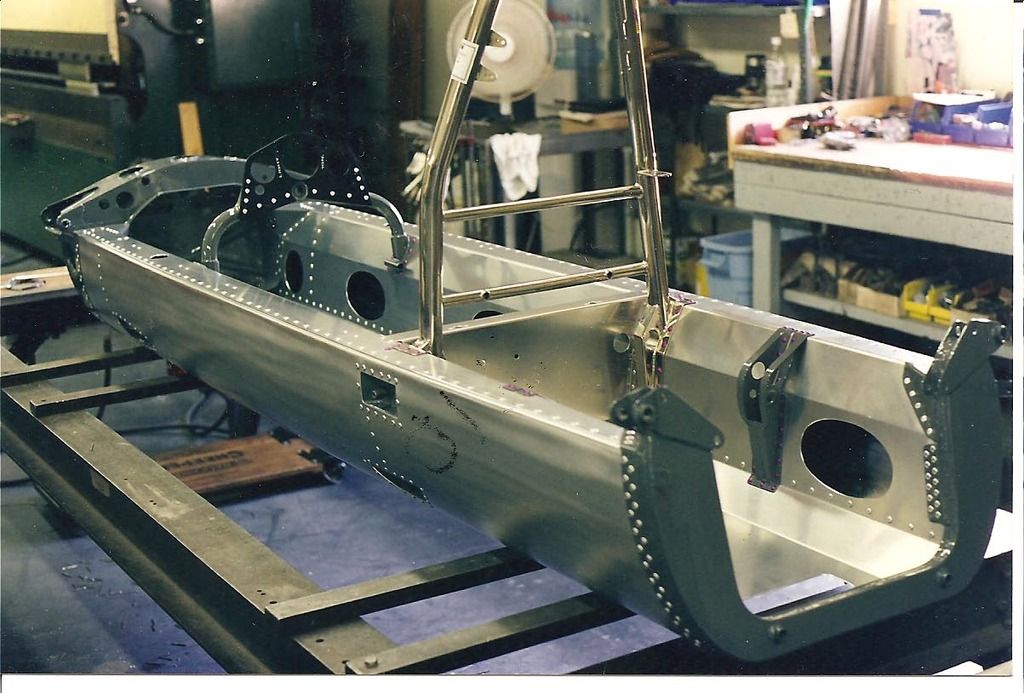

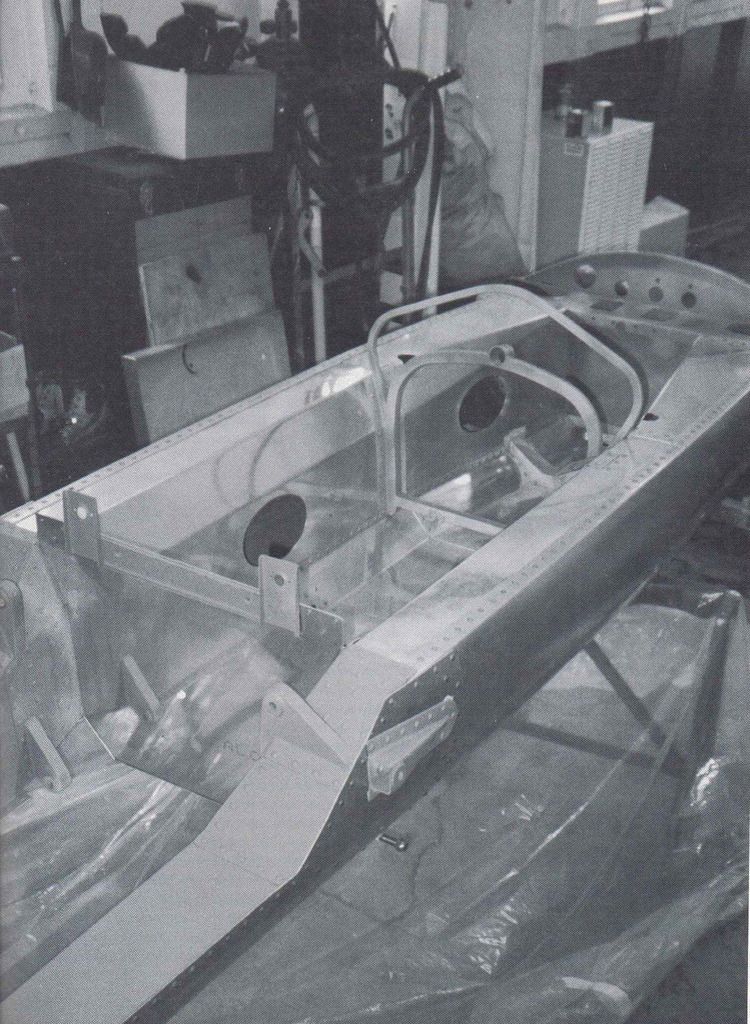

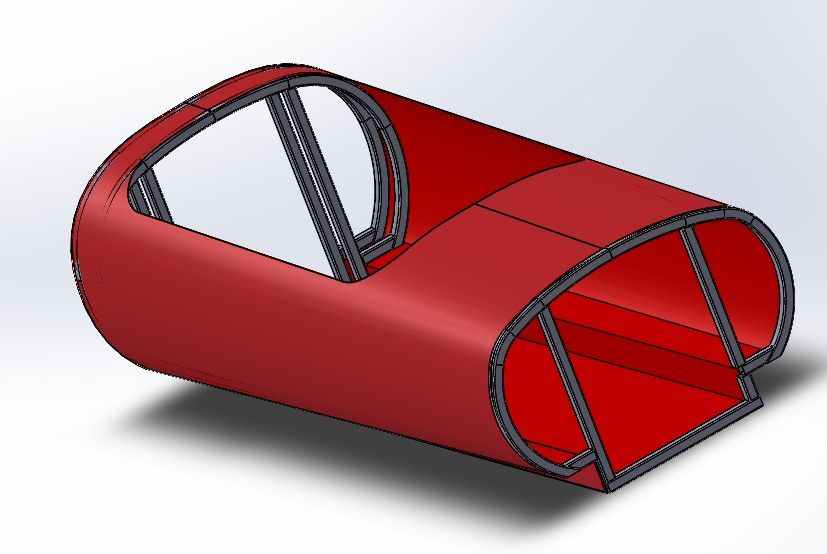

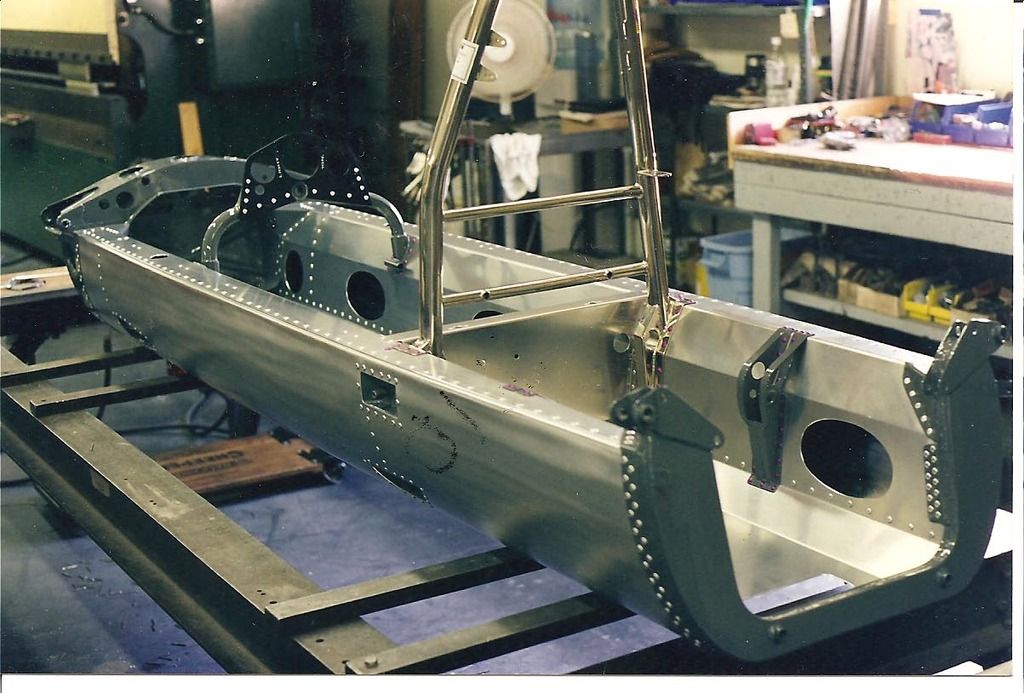

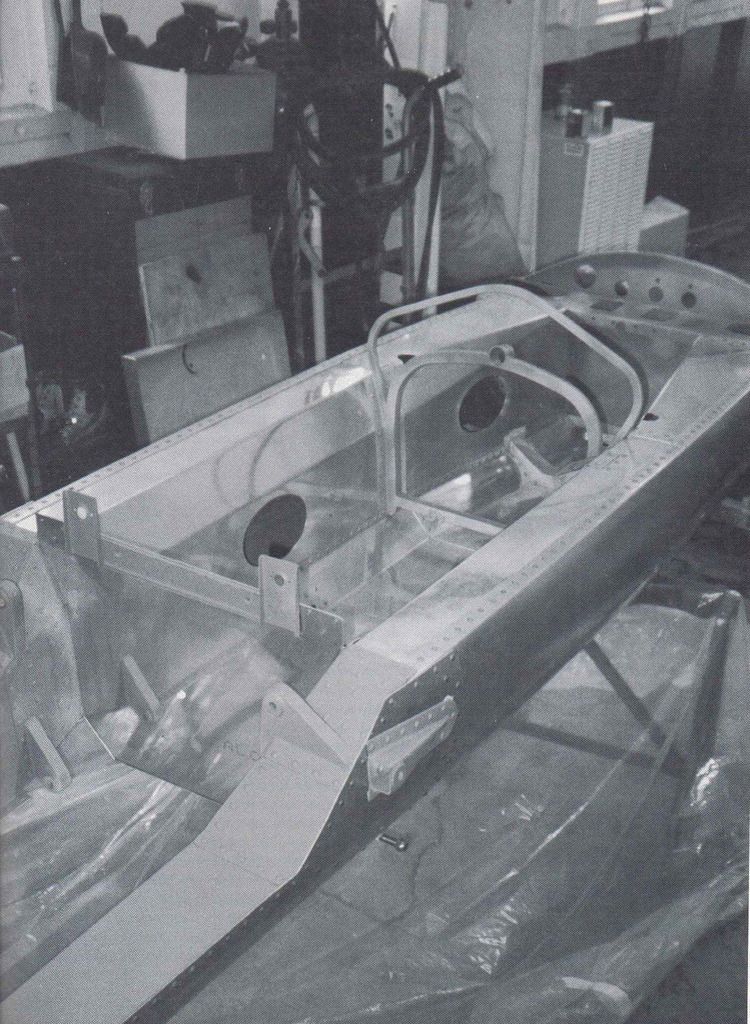

By way of comparison, this is a (replica) 49 tub under construction:

...and this is a cockpit shot of the finished article:

For the 25, get yourself a copy of the book

Lotus 25 by John Tipler, which gives a fairly good description and several photos of the tub construction.

[Edited on 10/6/16 by Sam_68]

ftaffy - 10/6/16 at 09:36 AM

Some what i already have for anyone who comes across this thread

ftaffy - 10/6/16 at 09:58 AM

Thanks Sam, as always a help.

The 25 is a fairly simple beast to reverse engineer how to make (also offers the option to make a 24 get things sorted and swap into a 25 mono) but i

like the 49 shape more.

I have been in contact with the builder of that replica, he has not been able to add much more around the skin construction.

What worries my is that the rivets are on the outside meaning the inner skin folds back under the outer... how the hell does that work?

Interesting to note the similarities between a 27 and 25, will go in look of some extra drawings.

For anyone really keen on the mono route take a look at this rebuild of a Lola, the square sided pods offer alot of benefits IMO.

https://primotipo.com/tag/john-turner/

[Edited on 10/6/16 by ftaffy]

Sam_68 - 10/6/16 at 10:24 AM

quote:

Originally posted by ftaffy

What worries my is that the rivets are on the outside meaning the inner skin folds back under the outer... how the hell does that work?

This may be a better image:

It appears the the outer skin just laps over the inner panels.

ftaffy - 10/6/16 at 10:44 AM

Since i started this i might as well add some more detail photos to continue what Sam has helpfully posted.

Another of the replica tub, this shows the outside folded in along the edges - this is voodoo work to me!

And he is making a 2nd chassis which is a spaceframe and will be a fibreglass skins like that of a 24.

Another cockpit (have more detailed photos split by chassis number on a laptop that i need to copy off)

[Edited on 10/6/16 by ftaffy]

ftaffy - 11/6/16 at 06:49 AM

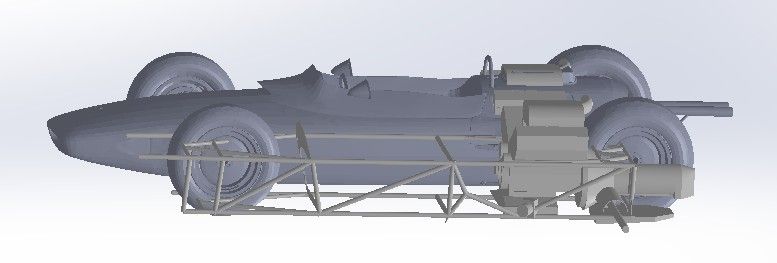

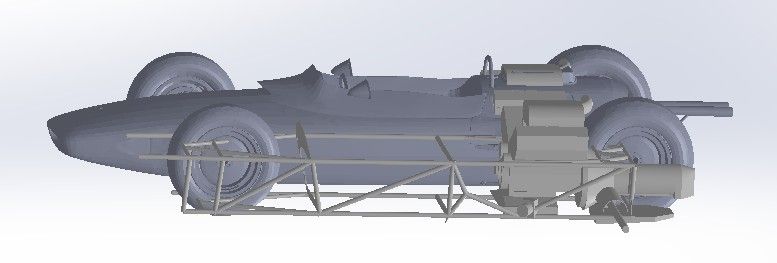

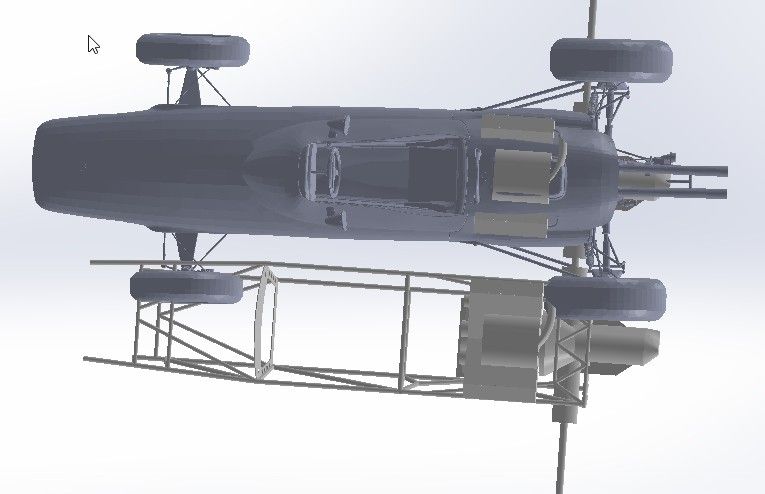

FYI used the one in the first post to make a model and it has some issues.

The best one to use is the "factory 49" perspective drawings with have a million lines on the nose cone to shape the body with. My

preference was to use the front and rear and loft between them. That was you can add the missing folded underside. Though you miss out on some of the

arc which is in the back of the car and its instead a straight line. Who ever drew this to start with didnt like the people who had to make it this

damn car curves around X, Y and Z.

Starting to research building plans... to try and figure out how to do the cockpit area easier then how they have it even if it means some mods to the

shape in that area as i can see benefits to the body wrapping as high as possible for stiffness.

Going to add an additional paid of bulkheads to be foam filled were the fuel tanks used to be for side impact protection, tank will only be behind the

seat.

Too add some more interest to the thread:

This is an elfin 100 mono, looks to use a steel frame with partial AL skin for load carrying.

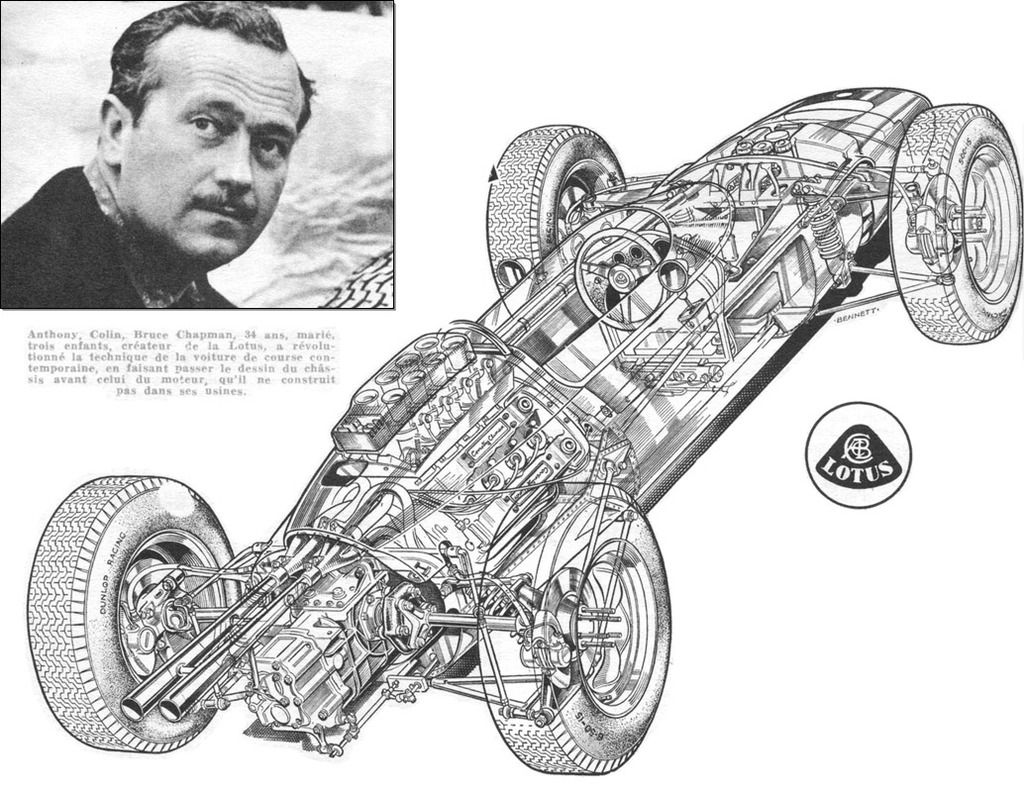

Gurney Eagle

And link to modeling mag for cars up to 1972

http://www.vsrnonline.com/Mags/MC/MC_Plans_1.htm

Cheers,

Taffy

Sam_68 - 11/6/16 at 07:43 AM

The Elfin looks interesting - not a car we're particularly familar with in the UK.

The Gurney Eagle shares a lot of DNA with Lotus, having been designed by Len Terry, of course.

What's the purpose of the car you're building? My worry with a straight 'replica' of the techniques used to build '60's

monocoques (single-skin panels an entirely riveted construction) is that they were reputed to lose almost 50% of their stiffness over the course of a

single season's racing.

If you're not too worried about the 'authenticity' of the structure, it might be worth looking at a variation of the Reynard-built

Formula Vauxhall Lotus cars, which were very simple, and have a reputation for being very robust, effectively using two huge aluminium

honeycomb 'planks' set on edge as their main structure:

Just found these in my collection of a tub without the outer skins, that better illustrate the junction around the upper edge of the cockpit that you

were worried about:

ftaffy - 11/6/16 at 09:02 AM

Thanks Sam, the plan was more about the style then rivet for rivet copy.

Besides using a 200hp v6 vs a 400hp v8.

Plan was to make a series of rolled shs ribs that have a frame which joins to the inner skin. Approx 6 were planned.

But open to other cost effective ideas thus the collecting of many ideas.

The issues with these is that the rolled outer skin went out of fashion quickly as I am guessing it was a pain to build and maintain be the square

frames seen a lot.

Cheers

Taffy

Sam_68 - 11/6/16 at 10:02 AM

quote:

Originally posted by ftaffy

The issues with these is that the rolled outer skin went out of fashion quickly as I am guessing it was a pain to build and maintain...

Dunno... I'm not sure how much of it was that, and how much was the aerodynamic fashion for wedges that was introduced with the Lotus 56.

Certainly, if you look at later cars like the Lotus 72 or Tyrrell 006, the sides of the tub are still 3-dimensionally curved, and just as difficult to

form, but the curvature gets 'lost' visually against the overall wedge shape.

But, for sure, I'd rather do a simple, faceted-flat panel tub and hide it within a curved outer shell of glassfibre or CF than to roll a dual

curvature aluminium outer skin.

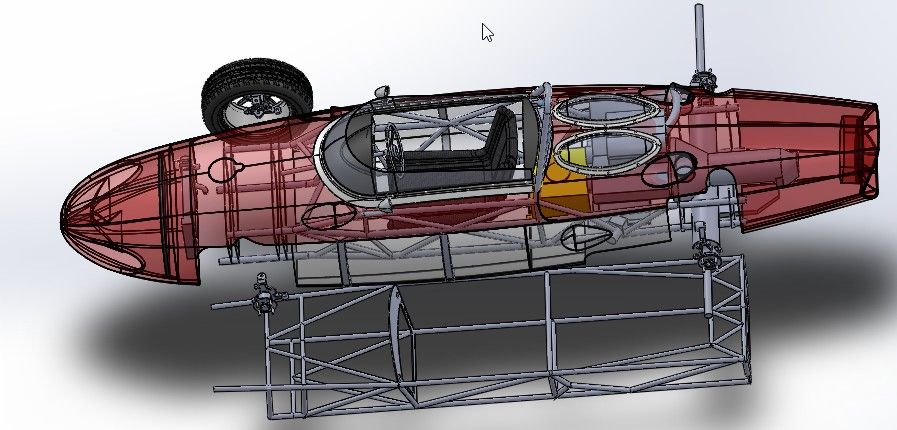

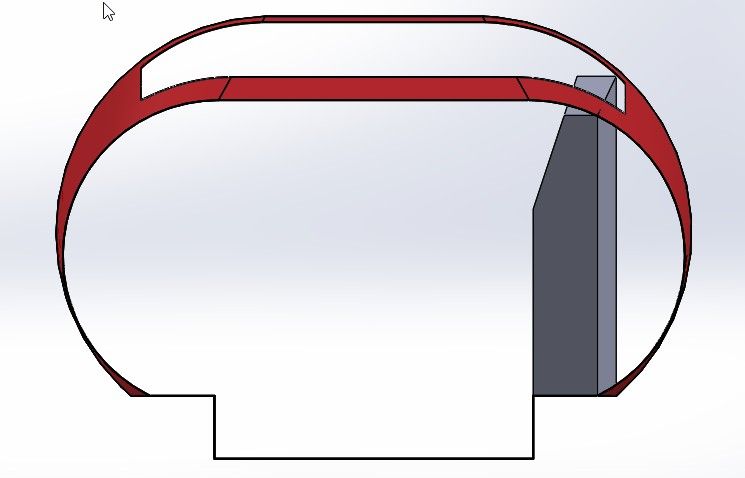

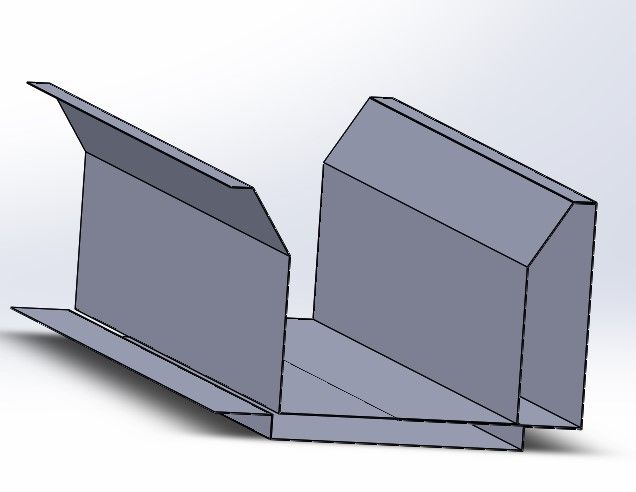

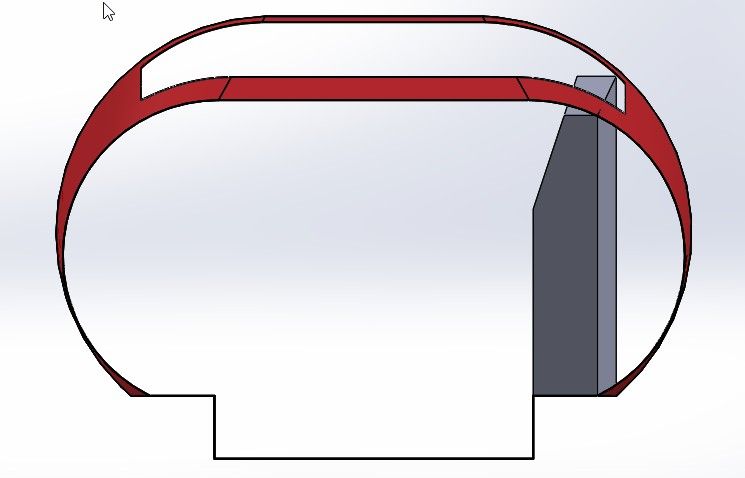

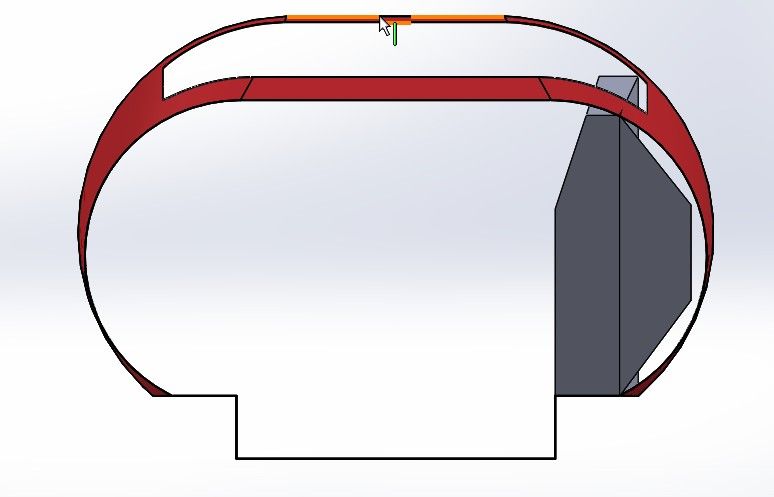

ftaffy - 12/6/16 at 07:17 AM

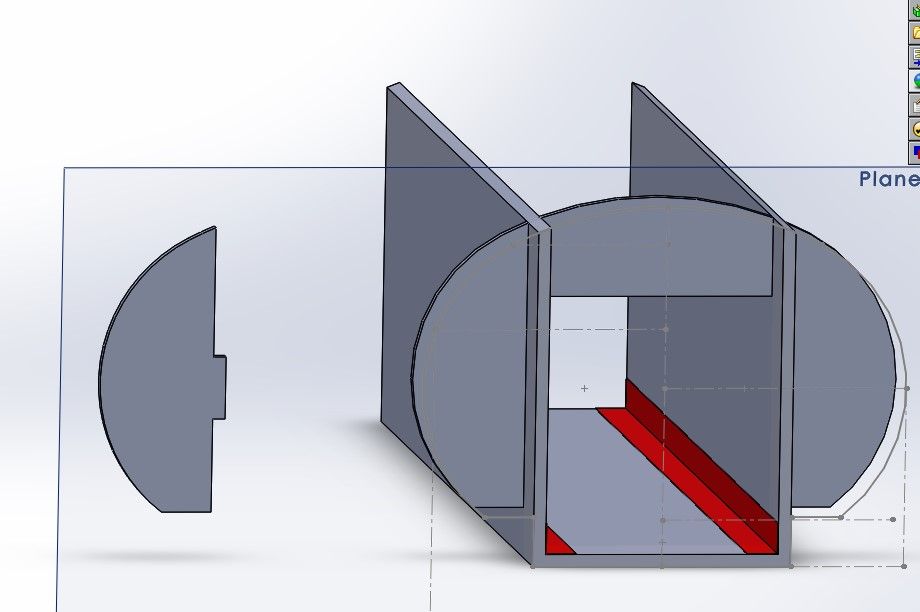

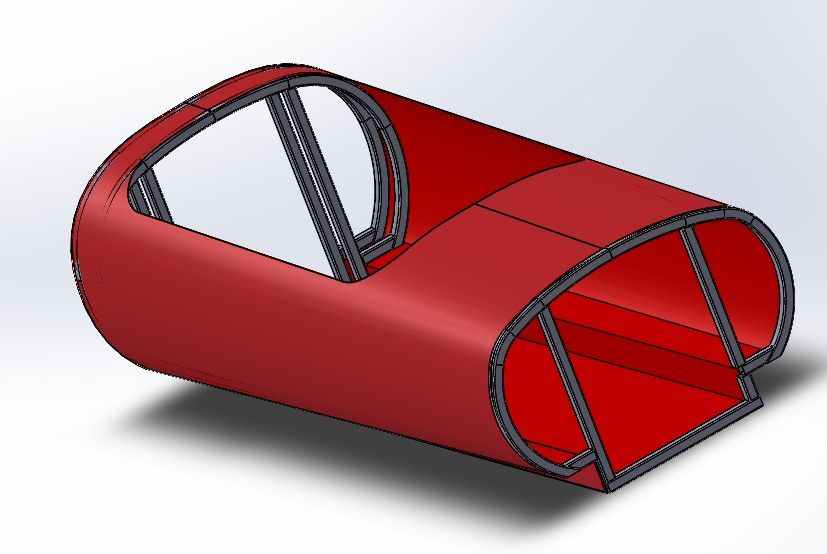

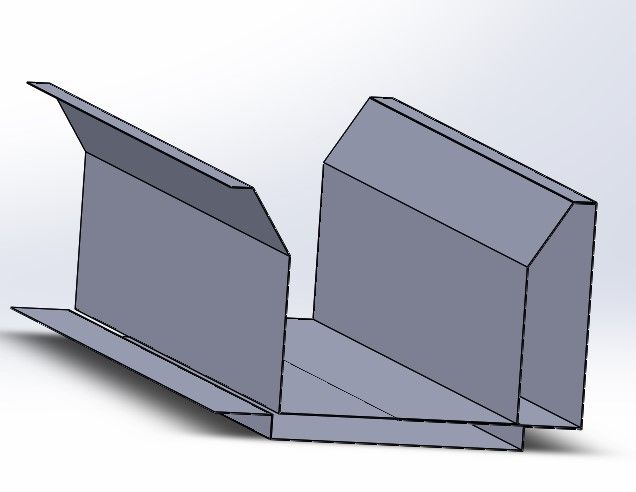

This looks similar to early sketch I had done before trying to include the outer body work in the tub

Then as you said slip a skin over to suit.

ftaffy - 12/6/16 at 08:24 AM

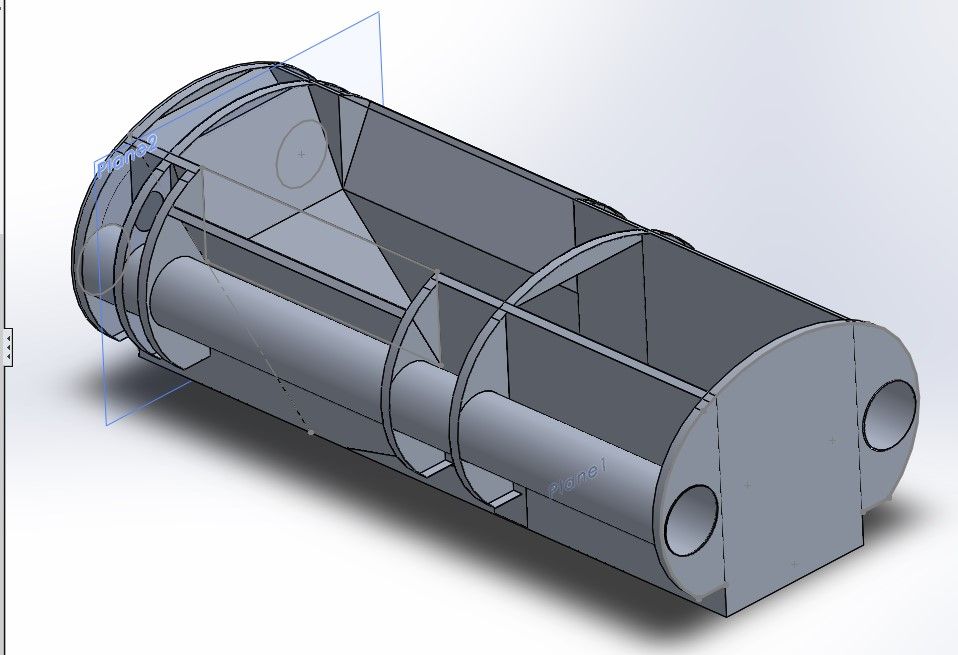

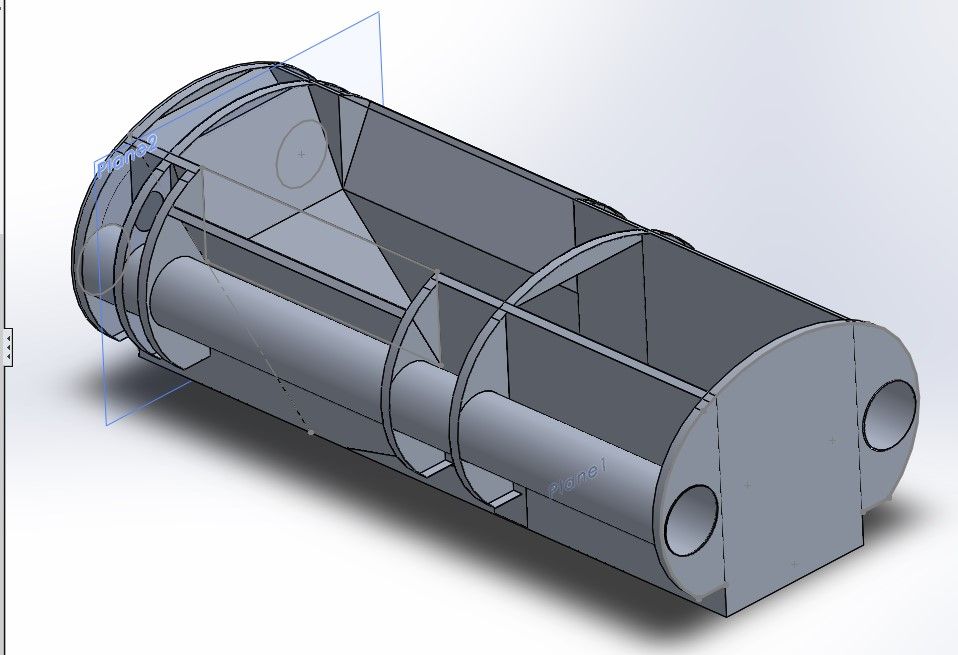

FYI this is what i meant for the car to have ribs inside the mono.

1 more full hoop at the end of the cockpit opening and 2 more incomplete at the cockpit sides which will be capped off with a horizontal tube. The

vertical tubes take the inner skin.

But bending these tubes would need to be CNC done as they have 3-4 separate curves in them each side... night mare or likely costly. Once they are

done skinning would be so much easier. A flat topped single curve does not look right.

You could always cut them from flat plate and make up some frames but that would be likely to warp given suspension will need to be mounted off the

front and rear of these not a great option.

Concerned its only you and me replying to this Sam...

Sam_68 - 12/6/16 at 09:41 AM

quote:

Originally posted by ftaffy

Concerned its only you and me replying to this Sam...

It's when you find you're talking to yourself that you need to get really worried!

Feel free to take the conversation to U2U/e-mail, though, if you prefer.

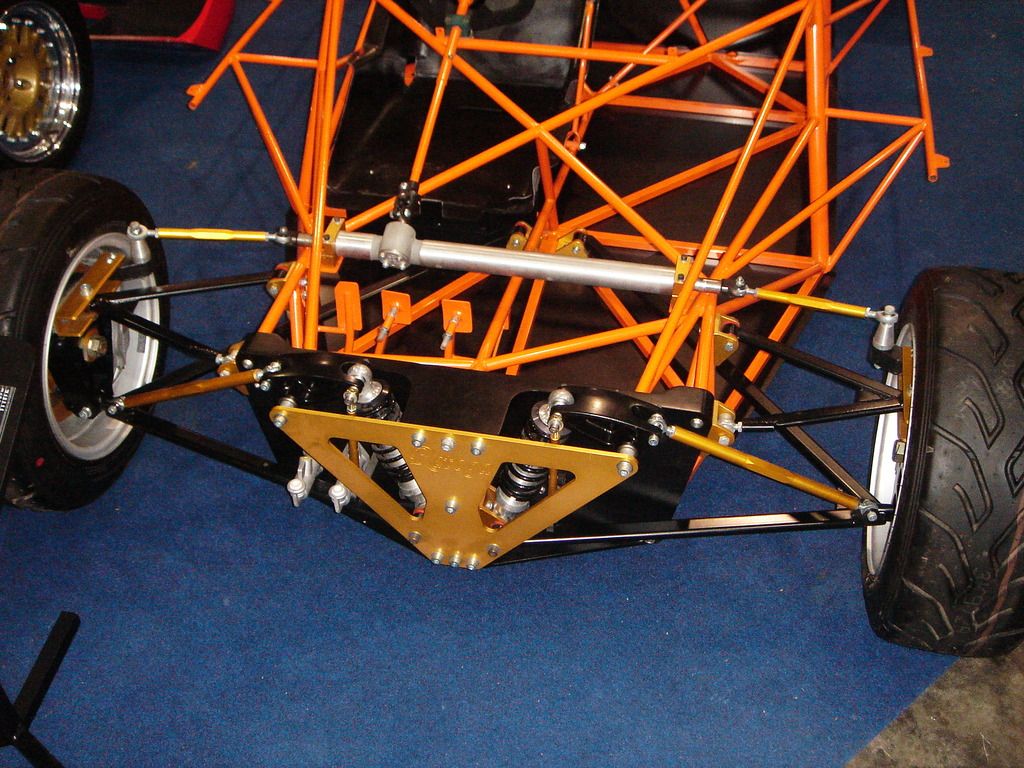

Your arrangement looks very similar to this old Cooper:

Link to website with lots more chassis images - look under the 'phase 1 gallery' for the chassis

construction.

Personally, I'd be more inclined to either use a simple, rectangular framework sandwiched between a couple of flanged sheets, to form a

diaphragmn bulkhead arrangement, or else do away with the tubular framework and just use a sheet diaphragm (in which case, these days, you might

consider honeycomb core material between the sheets to stabilise them).

Another alternative is a 'solid' bulkhead - in the old days, some manufacturers used cast magnesium, but these days we have the option of

CNC machined aluminium. Moderately expensive, but simple and potentially very sexy!

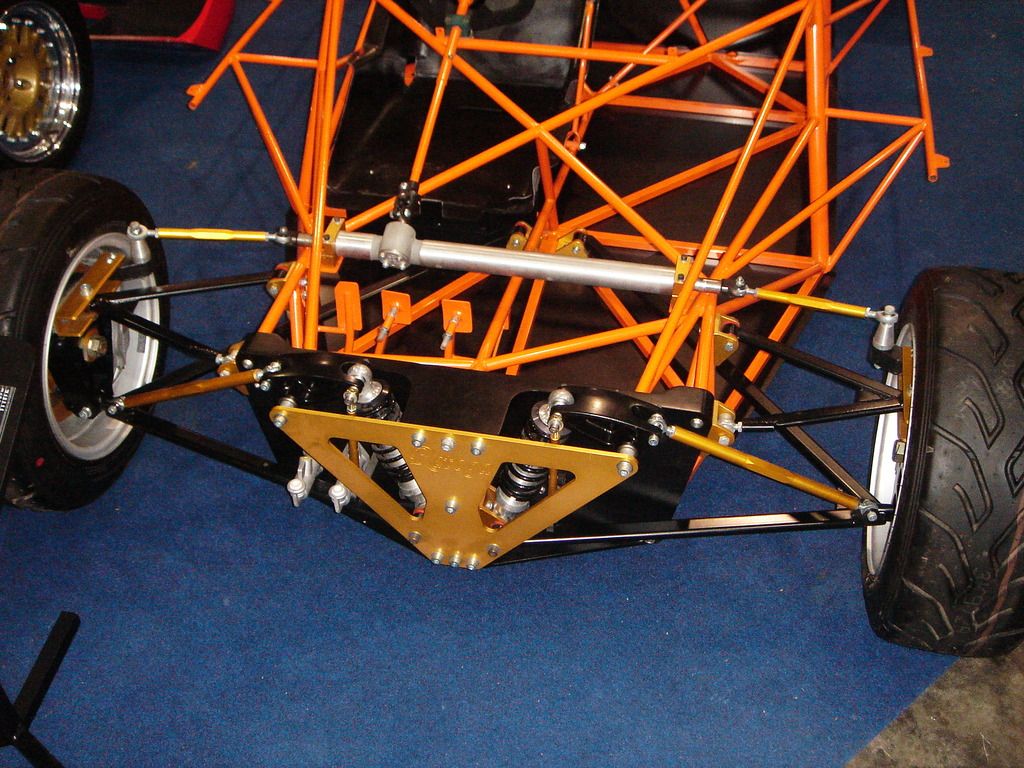

This is the Retoga (a spaceframe, obviously, but shows the sort of thing that might be done):

And this is the Australian PRB aluminium monocoque 'Seven':

And a cast front suspension 'subframe' on a more modern single-seater:

ftaffy - 13/6/16 at 07:57 AM

thanks for the suggestions. nothing commerical being discussed and i see very few actual discussions about the basic design for a garage build. Most

get into expensive honeycomb regions

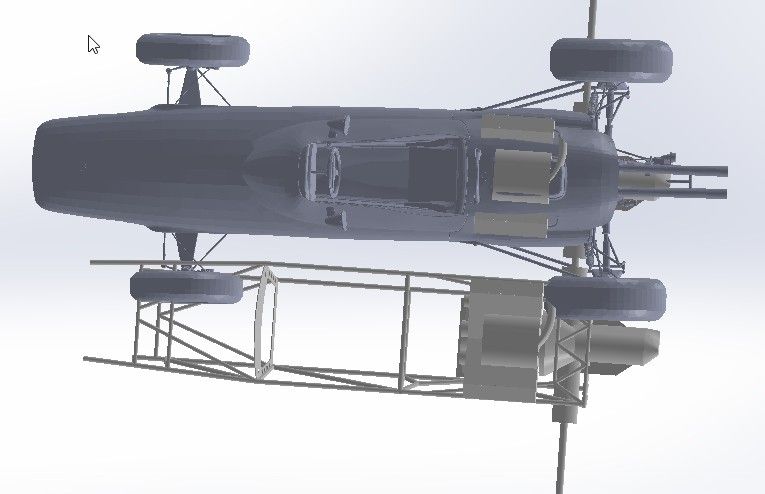

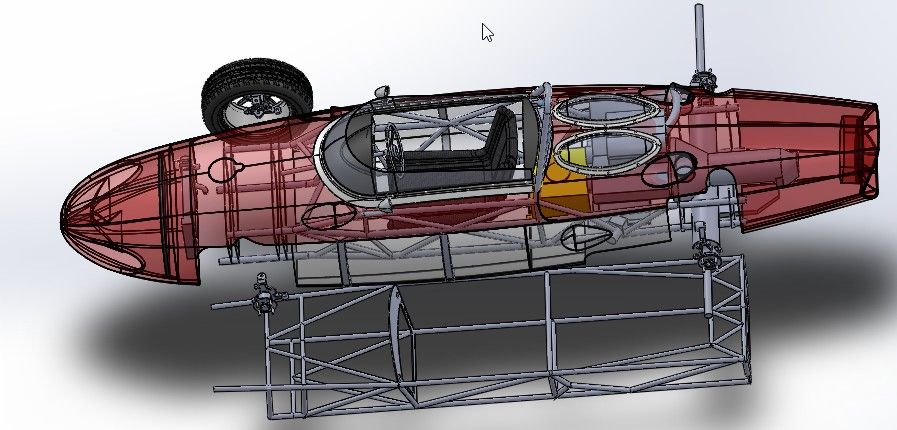

Wasted a few hours sitting in the garage with the dog, who despite being named Shelby is no help. So i did quick lotus 24 and dropped in vw v6 i have

on hand. The idea being i will see how the 25 goes shape wise, looks less double curve in the ally parts. i like that it does a dual function, a frame

and then a skin feels like extra work for nothing if making a mono.

Also dropped into the f156 model i have, note the chassis is not what was under the skin normally! Its a rough one based on more modern designs but

made to fit the skin, was what triggered the single seater but not likely to see the light of day.

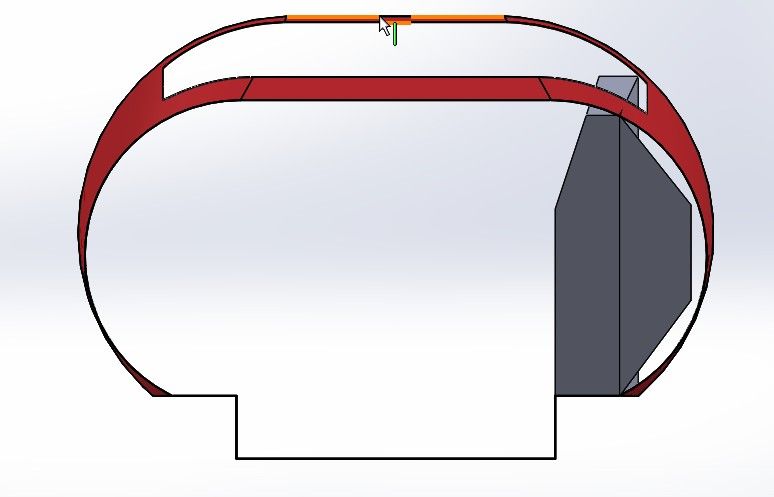

In terms of mono design did some concepts of a slip skin but has draw backs.

Simple side pod design creates this

An option is to change the shape but the only benefit i see is if this is made into another piece and foam filled.

The stand alone mono tub would start to look something like this.

My current thinking is it is not an exact replica and as such a solution that gets me a dual function skin and mono is to just simply the body curves

to allow them to be rolled in single radius bends. Need to add the nose and see about suspension points how it would look as it might just too off for

my liking.

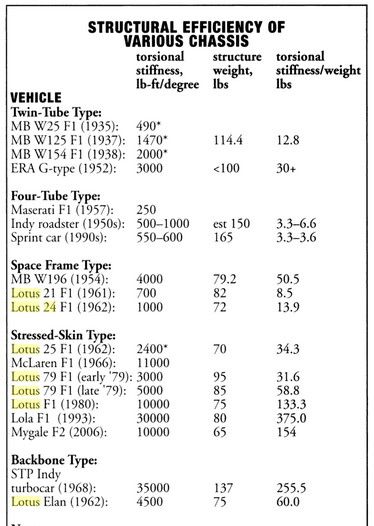

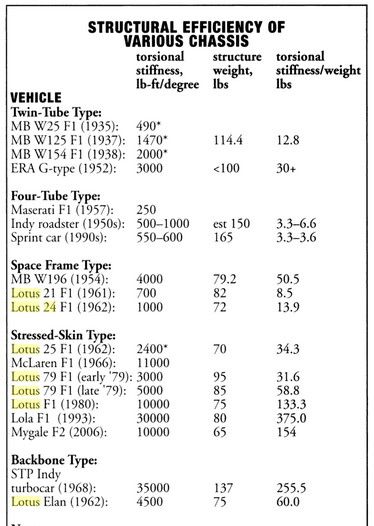

Came across this interesting chart about torsional stiffeness of various designs.

Sam_68 - 13/6/16 at 06:26 PM

That looks a nice little model of the 25 - how long did it take you, and what software were you using? Any chance of scrounging a copy?

The stiffness table is from a book called Race Car Chassis Design & Construction, by Forbes Aird, I think, but it tallies with information

I've seen elsewhere.

It's interesting in that the 25 monocoque gives about the same sitffness as the best current 'Seven' spaceframe chassis (without cage)

but for less than half the weight (not a fair comparison, though, I know, given that it's a mid-engined single-seater).

The Lotus 79 figure is bang on the money, too, but the guy who designed it told me it was about half that after a season's racing, and feeling

distinctly 'baggy'. Certainly not stiff enough to best exploit ground effect, and the 79's biggest flaw!

Also interesting, therefore, that the actual weight of the 24 and the 25 chassis are almost identical (ie. the advantage is stiffness, rather

than weight). If you lose half the stiffness over a season or two due to the rivets fretting and the panels stretching/relaxing, you're left with

no advantage... hence I think you need to think in terms of sandwich structures (massively better stiffness to start off with) and bonding as well as

riveting, to make it worthwhile.

ftaffy - 13/6/16 at 10:14 PM

Sam U2U Sent.

I have a copy of the Race car chassis design and construction book on order/its some place between England and Australia. Read that it had some good

information on monocoques... we will see how true that is.

The best for home building has been Stainfords and his references to the monopin.

Yeah was talking someone who has a chevron and they gave me some tips on how they did the bond/rivet set up, do have a decent starting point when i

get to that detail. I glued and riveted the panels on my locost to make it stiffer and it was nearly 5000Nm/deg before any panels.

Will retrace your 25 drawing and see about modeling that up and as the shape looks nicer possibly for the home builder, though my preference is still

the 49 but build ability may drive the design direction.

Appreciate the comments/photos.

Sam_68 - 13/6/16 at 10:30 PM

My understanding is that bonding as well as riveting is only a partial solution to the problem of loss of stiffness, mind you.

The other part of the problem (apart from fretting and stretching of the rivets) with a single-skin aluminium monocoque is the basic ductility of

aluminium.

Essentially, it stretches a bit in service, with the more highly stressed areas stretching a bit more than lower stressed areas, so that the whole

structure can then 'oil can' to some degree (ie. localised and limited buckling of the panels to 'take up the slack',

analogous to the way you can 'pop' the side of an old rectangular metal oil can in and out under thumb pressure). Honeycomb helps this, as

it stabilises the panels against this localised buckling.

Of course, the other solution is to use a material that is not anything like as ductile as aluminium - for example fibre composites - but we probably

don't want to go there.

ftaffy - 13/6/16 at 11:22 PM

True, didnt think of the skin stresses variation over the length of the body... was only thinking local stresses at the rivets being better spread by

gluing.

Would be interesting to see that in an FEA form, guess i will fix up one of the simple skin bodies and get some framework in it and make a colorful

picture to understand what is happening - note this wont actually give torsional strength or any useful number apart from see the high stress areas,

my knowledge limits me to me single piece FEA, ie an upright.

Hmm too many design directions at once... need to quit my job and do this full time.

1. 24 spaceframe

2. 25 Mono

3. 49/25 FEA of ribbed semi-mono

4. Sandwich design options

5. Rolled outer skin vs box mono with slip over chassis

6. Selecting which Al to use (Been suggested 5052 but see that a lot use 6061. 5052 was noted by Lola builder as being too soft... Notes seem to say

stay away from 2024 as its too hard to fold without cracking.) As this will drive the bend radius i can design with. Or make it a heavy weight and use

mild steel and no rivets all welded design.

http://www.aircraftspruce.com/catalog/mepages/aluminfo.php

Will start knocking that list off this week hopefully and see what direction comes out

[Edited on 13/6/16 by ftaffy]

ftaffy - 3/7/16 at 10:56 PM

quote:

Originally posted by Sam_68

What's the purpose of the car you're building? My worry with a straight 'replica' of the techniques used to build '60's

monocoques (single-skin panels an entirely riveted construction) is that they were reputed to lose almost 50% of their stiffness over the course of a

single season's racing.

If you're not too worried about the 'authenticity' of the structure, it might be worth looking at a variation of the Reynard-built

Formula Vauxhall Lotus cars, which were very simple, and have a reputation for being very robust, effectively using two huge aluminium

honeycomb 'planks' set on edge as their main structure:

[img]https://racecarsdirect.com/content/UserImages/58843/390297.jpg?v=1[/img]

[img]https://racecarsdirect.com/content/UserImages/58843/390298.jpg?v=1[/img]

Hey Sam,

A question about the planks, after doing a wood mock up i can see using both methods but are the tops of the 'plank' just a AL U

riveted/glued on?

Cheers,

Taffy

[Edited on 4/7/16 by ftaffy]

Sam_68 - 4/7/16 at 08:03 AM

Dunno, is the honest answer.

The photos appear to show no joints, which seems to suggest that the 'planks' might be folded from a single sheet of alloy to form a

continuous, deep inverted-U section, with the honeycomb and hardpoints bonded in afterwards, but it's a very long time since I've seen a FVL

in the metal, and I really can't remember.

You might try asking around the FVL spares suppliers, or people still running them, or even drop Adrian

Reynard a line?

ftaffy - 4/7/16 at 10:05 PM

Its not a big deal unless i find a place that sells planks perfect for my use...

In good news though i got to sit in my wooden tub and found out i cant reach the pedals, somehow added the pedal space twice to the length. Annoying

mistake but cheap in wood offcuts vs anything else.

Also found a 110% tub with 1in extension to the lower U in the 49 makes it sit flush with the VW V6 rockers, though looks like the car will be running

a 1in higher ground clearance due to the gearbox outputs. Considering the original was around 4in hopefully wont impact appearance with some

creativity.

Cheers,

Taffy

rodoe - 7/7/16 at 02:24 AM

Hi guys,

I've had the same desire to build a lotus 25 style mono with a bike engine.

The engine is wider than the inner tub so will use frame at rear. After talking to

an Elfin Mono owner, he strongly encourage the rear frame idea as working on the

enclosed engine is a bugga.

I first got the idea after seeing the restoration of an Elfin Mono,

they look simpler than I thought they would be.

Anyway, www.bahnerengineering.com has a few pages of amazing quality

images of monocoques of all types and sizes.

After a bit of reading I was under the impression that 2024 T3 was the

way to go skin wise, using Cherry Rivets and then bonding as well. But you mention

other grades and that stretching may be a problem.

I'm wondering if the inner tub were honeycomb would that help (sorry, I am no engineer

and you seem to be so ).

You may also find this thread on uphill racers forum interesting. http://www.uphillracers.com/showthread.php/open-wheeler-build-6443.html

Sam_68 - 8/7/16 at 12:03 AM

quote:

Originally posted by rodoe

I'm wondering if the inner tub were honeycomb would that help (sorry, I am no engineer and you seem to be so ).

Not me - dunno about Taffy! My main career is in architectural design - engineering design has always just been a sideline, for me (though structures

are structures, to some extent - just that buildings don't move quite so fast  ).

).

As I understand it, honeycomb helps a little with preventing 'relaxing' of the tub (though it's bonding as well as riveting that

makes a bigger step), since it stabilises the skins against 'oil canning' - localised buckling of the skins that means the

'buckled' section is doing no work, which then turns into a vicious circle: the 'oil-canned' section does no work, so the

neighbouring metal is worked harder and, being ductile, stretches a tiny bit over repeated loading cycles, expanding the oil-canned area, and so on,

in circles...

My approach when I was looking at this sort of design was to opt for a V-twin, which is narrow enough to match the width of my fat arse. That was also

partly on the grounds of weight and the fact that I don't like the stressy noise of 4-cylinder bike engines when combined with the short gearing

of a car, though... but admittedly V-twins sound wrong if you want the scream of an F1 car.

Nice links, by the way!

rodoe - 8/7/16 at 05:55 AM

I have contact with one Elfin Mono owner who hasn't had his car long, but he knows another long term owner who frequently races his Elfin mono.

He is a older racer who was quite a successful formula ford campaigner in his younger days so I am sure he will have an idea as to the subtle changes

in chassis stiffness over the years he has driven it. I will question him.

Ensign F3 cars were an interesting transition from spaceframe to mono as seen in the photos from http://www.ensignf3.com/[url]

Sam_68 - 8/7/16 at 07:56 AM

Not a single-seater, but the Andre/Reynard Inverter

uses a hybrid solution too, of a very simple spaceframe, reinforced with stressed sandwich panels instead of triangulation to form a monocoque

structure.

Lots of interesting drawings on the above link, and all free to download in both CAD and pdf format.

rodoe - 11/7/16 at 08:07 PM

Thanks Sam, had checked the Inverter out a few years ago but forgot about the the chassis stiffening there.

As for the 'oil canning' issue, i read an old air sheetmetal book written for US aircraft builders

in possibly WW2 days. Their practice was to run (and i forget what they're called now) stringers or ribs every 20 inches

of sheet aluminium. Looking at the Elfin mono bare chassis or the Elwin with the outer sheet removed, you can see the extra ribs for stiffening.

I wonder what help this would be to preventing the Oil canning issue?

ftaffy - 13/7/16 at 02:46 AM

Nice links, thanks. Enjoying taking a look at the build blog.

While i am an engineer i dont work in this field, so take any of my comments with a grain of salt.

The extra stiffeners along the chassis is something i am keen to do, i believe that it would reduce this in that it will isolate the zones more. But

obviously 1 weak area stuffs the whole thing, but the same is true for a locost chassis. Make the entire car super stiff but have 1 weak area it will

fatigue and fail over time.

The 25 had these along its length while the 49 removed them, seeing the crash pictures they didnt seem to matter strength wise but even those cars

which ran on for a few years in private hands seem to have on going mods and i would guess they got refreshed. They were not glued which would have

made it easier to do.

The lotus 35 had a steel inner U of something around 0.8/1mm at some stage in its life as opposed to the AL U seen in the 25/49. Thinking about

copying this as it opens up a few other options for me with a small weight addition. To me that is not critical given this is not to win sheep

stations, but for the fun of it. Means i can weld the damn thing together instead of 3000 rivets.

If i was racing and wanted this shape i would go the honeycomb core and keep the additional bulkheads with the outer single skin, take a look at

'The Race Car Chassis' by Forbes Aird for info on materials in chassis including monocoques.

Also note that the 25 was not that good of a design, without the rigid mounted engine the torsional strength was less then half the strength.

A fully steel mono core is around 60kg

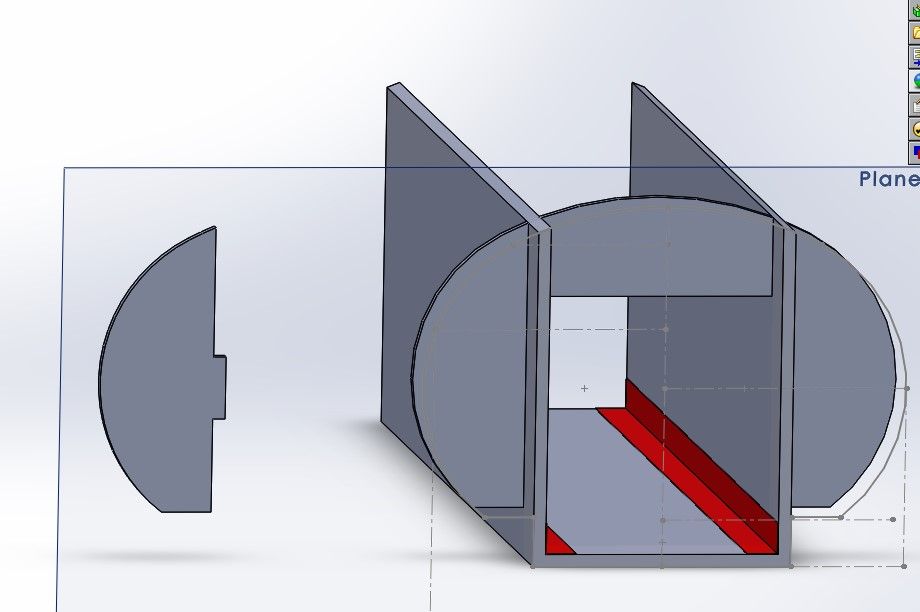

What i mean by honeycomb and keeping the additional formers/ bulkheads.

The 25 data:

Tub 12in deep

Outer skin 16 gauge L72 Alcad (R4 onwards, before that 18 gauge)

Inner skin, floor, seat back 14 gauge

Engine bay inner skin 20 gauge.

The inverter would be a great project to build but alot of machining and custom body work required, a group build would be a better option if one

wanted to do this IMO.

Rivets wise, my knowledge is limited, i used simple pop rivets in my locost. But if you want to play monocoques i would be using solid and really

thinking about the flanges in stressed areas. The idea of just cutting slots in an angle, bending into a curve an riveting it on to is not a good idea

for anything more then a radiator shroud.

http://www.gt40s.com/forum/lola-t70-lounge/22490-lola-t70-scratch-bu

ild.html

Been keen to hear what you come up with, happy to keep putting what i have on the table as i no commercial interest in this field.

Cheers,

Taffy

rodoe - 13/7/16 at 01:37 PM

Good point about the engine stiffening the chassis. I'd read that before and thought if i put a bike engine in, with its mounting points it

won't really add much stiffness.

Apart from this, I've been offered access to a Brabham body mold and so looks like the mono dream will end for something more traditional.

As for those models you put up Taffy, those pipes running the length of the chassis were retro fitted to one of the Elfin Mono's when it was

restored many years ago (was privy to the rebuild photos).

Lola T70, mmmmmmmmmm (insert Homer Simpson drooling here).

The all steel outer skin sounds like a great idea, easy to weld and all. Another idea is to go the Alan Staniforth method (used in the Terrapin , for

which i have the book and plans) of space frame chassis witb outer side skins of aluminium for extra stiffness.

Will be keeping a keen eye on this thread though.

Rod

Sam_68 - 13/7/16 at 02:53 PM

quote:

Originally posted by ftaffy

...obviously 1 weak area stuffs the whole thing, but the same is true for a locost chassis.

As an aside, Axion/Westfield used that as partial justification for the reason that only the centre tub on the new Westfield prototype chassis is CF,

with spaceframe subframes front and rear: one of their objectives was a 30% increase in total stiffness, but to achieve that, they needed a 70%

increase in the stiffeness of the cockpit section, which is the weak area on the typical 'Seven' chassis. By comparison, the engine bay was

less crucial, and the spaceframe made sense for flexibility of different engine installations in this area.

quote:

Originally posted by ftaffy

A fully steel mono core is around 60kg

I would have to ask myself what the point of a monocoque was, other than 'because I can', at that weight: for a small single-seater

it's easy to do a steel spaceframe of perfectly adequate stiffness for quite a bit less weight than that. Hell, I've just done a 2-seater

'Seven' spaceframe (complete with traditional 'weak' cockpit bay and stressed for 300+ bhp and slicks) that's a good chunk

lighter than that!

quote:

Originally posted by ftaffy

Rivets wise, my knowledge is limited, i used simple pop rivets in my locost. But if you want to play monocoques i would be using solid and really

thinking about the flanges in stressed areas.

Google 'structural pop rivets': you can get blind rivets that are designed to give high strength in both tension and shear, and use of these

is normal practice in monocoque tubs. There's plenty of advice available from manufacturers.

Neville Jones - 13/7/16 at 05:38 PM

The easiest way of solving the torsional problems in cars with open cockpits(ie '7' type cars), is fit a full cage with diagonals. The rest

of the chassis then becomes the soft areas, not the caged areas.

Not a lot of help for this chap with his open wheeler though.

Westfield??? Just another gimmick, to try and resurrect sales.

[Edited on 13/7/16 by Neville Jones]

Sam_68 - 13/7/16 at 07:01 PM

quote:

Originally posted by Neville Jones

Just another gimmick, to try and resurrect sales.

Just another gimmick to try and extract large sums of money from the Government, in fact.

And very successful at it they've been too... this has been the 6th funded project that Westfield/Potenza have undertaken in the last 4 years.

My bet is that they're making a lot more profit from NVN funding bids than they are from manufacturing cars, just at the moment.

ftaffy - 13/7/16 at 11:34 PM

quote:

Originally posted by Sam_68

quote:

Originally posted by ftaffy

A fully steel mono core is around 60kg

I would have to ask myself what the point of a monocoque was, other than 'because I can', at that weight: for a small single-seater

it's easy to do a steel spaceframe of perfectly adequate stiffness for quite a bit less weight than that. Hell, I've just done a 2-seater

'Seven' spaceframe (complete with traditional 'weak' cockpit bay and stressed for 300+ bhp and slicks) that's a good chunk

lighter than that!

But what is the torsional stiffness:weight? i made a ~5000nm/deg locost with no roll cage that is dragged around by BMW M44 (135hp, a lot less then

what you are talking about). Total weight wet was 650kg, not the lightest i will agree but if you take a look at a <2000NM/deg westfield (Real

world test) that comes in at 550-600kg (dont know the final figure as the car has been modified a few times). What is better?

The 24 and had basically the same weight but the 25 was much stiffer and considered the better car, but there must be a tipping point some were in all

that and for racing that will probably be weight. I remember the story of MP4/1 that they designed it the same as a AL honeycomb and ended up 3-4

times the stiffness at the same weight, so cut it down to only be ~double the stiffness but was 25%? lighter (memory is foggy on the exact figures but

does indicate at that leveling the thinking is weight is king vs stiffness).

You can cut the design above down by another 10 maybe 15kg (lightening holes, use AL in a couple of simple areas, etc) and still have a fairly

straight forward build. Laser cut all the panels with tabs for self alignment when assembling, have the U folded up by the cutter on a ~2m brake.

Small 300mm roller for the weld on flanges on the bulkheads, small <1m folder for the rest of the panels and away you go welding up the joints. The

idea is accuracy you wont get with a space frame without making a lot of jigs and stuffing around, with the strength a mono offers and the easy build

mild steel will give you all at the sacrifice maybe 10% of the total weight.

For those coming from a Locost with only backshed tools not may will be skilled beating AL to a near enough shape, then flattening using a an english

wheel, forming a flange and then safely preparing, gluing and riveting 3000 spots on a car. The end goal we are looking at is different, a cheap toy

vs a race car.

If i was going for a winning race car i would ditch the VW V6+ road car uprights + the skin type mono, go a bike powered honeycomb chassis as you

suggest. Remove all weight possible, custom uprights, etc.

For reference sake, weights of 1960's race cars we are talking about:

Lotus 49: ~530kg (Engine was 168kg of that, chassis: No idea sadly...)

Lotus 25: 452kg, with a chassis weight of just 31kg...

The odd ball is the space frame W196 weight 10% more then a 25 but over 50% stiffer. Good design by the Germans.

A big take away i learnt from time in F-SAE was a simple car finished and tested will beat an advanced minimally tested one. So always work towards

the simplest solution even if its not the absolute best.

quote:

Originally posted by Sam_68

Google 'structural pop rivets': you can get blind rivets that are designed to give high strength in both tension and shear, and use of these

is normal practice in monocoque tubs. There's plenty of advice available from manufacturers.

Thanks will take a look for those, like my pop/blind rivets as opposed to solid.

One area that always worried me with these designs is the floor being just a single sheet flat sheet. In my locost i made the floor a swedged shape

like what you do in retaining walls/ ships bulkheads to stiffen it, the use of a single sheet worries me.

I am worrying about nothing as people keep doing it without major effect?

Cheers,

Taffy

Neville Jones - 14/7/16 at 08:52 AM

quote:

Originally posted by Sam_68

My bet is that they're making a lot more profit from NVN funding bids than they are from manufacturing cars, just at the moment.

That's a fairly sad statement on the state of the company.

They should be making many, many times more profit from genuine sales, than the small amounts(relatively) that come from their possible portion of the

NVN grants.

-------------------------------

To stiffen the old style chassis in the cockpit area.....needs bigg side additions, to bring up the numbers, then a smooth transition into the front

and back.

Start the design from the cockpit, and work outwards, and not design the chassis hen try and stiffen the cockpit. Back to front thinking!

Cheers,

Nev.

rodoe - 24/7/16 at 08:05 PM

An aside question here. How are the lotus 25 front rocker arms made? Google gives no clues.

Sam_68 - 24/7/16 at 08:32 PM

quote:

Originally posted by rodoe

An aside question here. How are the lotus 25 front rocker arms made? Google gives no clues.

They were fabricated from 16 gauge sheet steel, including an internal lattice web, pivoting on 1/2" bolts though needle roller bearings.

ftaffy - 15/8/16 at 03:12 AM

Rodoe, Any progress on your build?

I came to the conclusion a 49's shape is simply too complicated for a first round, the 25/33 is must more suitable as a stepping stone.

Nothing exciting to show for all of that, but essentially going widen the car 360mm tub with 2 180mm D's. Keeping the same wheelbase but slightly

widening the track to sit between the 25 and a 49 to suit the golf mk3 rack and the drive shafts off the 5HP19 gearbox (VW Passat).

Again not going to run fuel tanks in the side pods, a single ~20L tank behind the seat which will mean a slight extension to that space which is fine

as the V6 is shorter then the V8 and would have been dead space anyway.

The other benefit is the extension of the tub backwards of the seatback is mild steel which means you can weld on engine mounts, etc without fatigue

concerns if it was AL.

Also racking up the hours reading aircraft construction and metal working books. Been holding off pulling the trigger on buying the english wheel, etc

until i finish the design and really commit i am going to do this thing.

Cheers,

Taffy

ftaffy - 6/5/17 at 12:39 PM

This might inspire some people:

http://www.gt40s.com/forum/wings-wheels-keels/49645-lotus-38-ish-re

plica.html

Mono Lotus 38 inspired build, great detail in the photos.

Sam_68 - 6/5/17 at 02:49 PM

Very nice!

"Then it was just a matter of translating each paper component to sheet metal..."

The man is a master of understatement!

sam919 - 14/5/17 at 09:32 PM

Great thread guys, very interesting about chassis design....keep the pics coming !