Sorry but had to tell - chassis was on its wheels on saturday - front and rear mx5 uprights IRS etc. pics

http://www.locostbuilders.co.uk/photos.php?action=showphoto&photo=bumpsteer.jpg

and

http://www.locostbuilders.co.uk/photos.php?action=showphoto&photo=2rear2.jpg

Sorry about the bandwidth....

BTW 1st picture shows laser pointer (aka gunsight) used to check rack location. height is really sensetive - half a millimetre makes a significant

difference! With the modified mx5 uprights I have to shorten an escort rack by 3.5"

cheers

Bob

Looking good Bob. Engine in next

Do the rear dampers work horizontally Bob? I read somewhere they need to be specially valved to run level or inverted.

Hah - no it's just been placed there while I messed about.... final position is vertical from bottom bone to shock tower passing in front of

driveshaft & top wishbone.

The design work I did using solidworks has paid off 'cos everything that should touch does & everything that shouldn't doesn't! I

have a couple of bits to revisit (note front susp has too much droop (missus) and I need to beef up the rose joint clevises at the back) but I see it

as a big milestone to get it on its wheels so am pleased as punch!

Bob C

Building from your own design adds risk and effort, but no doubt an extra inch on the chest!

Looking great, Bob

[Edited on 22/6/04 by pbura]

Great idea re the gunsight ! can you eliminate bump steer at the front?

yeah but it means slicing 3.5" off the rack. The gunsight makes it very easy to adjust & see the effect. I'm using non standard uprights

so don't take the 3.5" figure as right for you!

With rack height wrong the steering (on one wheel) moved left/ right as the suspension goes up/down. With rack length wrong the dot trace on the far

wall becomes a curve. With everything right you get a nice straight vertical line. A millimetre of rack height error was giving me a trace at 45

degrees - like I say, very easy to adjust!

Rack is being shortened right now..... I may be forced to limit lock a bit when I shorten the rack - I'll post any issues in the running gear

section.

cheers

Bob C

Without the laser on the axis of the wheel will it not scew your bump steer as the camber of the wheel changes with the movement of the wheel up or

down. I am playing with the same issue right now.

Dale

Good point Dale. Maybe it's best tied onto the steering arm itself?

OK rack shortens 3.5" with no issues (other than stock mounts now a bit close together). If laser beam is horizontal it points in the direction

the wheel will roll. If chassis wishbone pivots are parallel & horizontal then laser will stay horizontal as suspension moves. OK the line on the

wall should be a slight curve because the wishbone ends describe an arc - fraid I'm not that accurate.....

So now I'm thinking about mounting the rack via the gaitor clamps, hmmmmmm

TTFN

Bob C

Bob,

Your idea is genius, I've used a cheapo laser pointer & it works really well. I guess the greater the distance between the laser & the

dot trace, the greater the accuracy.

My bump steer was terrible, I raised the rack 40mm & it still isn't enough, altho I've reduced the bump steer to about 25% of what it

was.

In my case I can raise the rack further, but I need to re-route some plumbing to make room....

I guess if you are good at trig, you could somehow measure the amount of bump steer in degrees, altho as you say, just aiming to get a straight line

on the trace is enough....

Rescued attachment laser.jpg

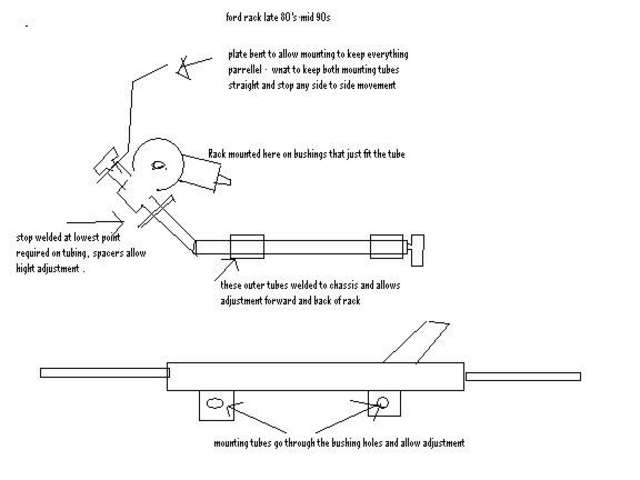

Here is a crappy diagram of how i made my rack adjustable in height and horizontal.. it is mounted on 2 tubes with an bend in them and bushings to

allow the rack to move up and horizontal..

Dale

Rescued attachment ford rack adjustment.jpg

Hi Bob

Chassis looks great

Just one question about the rod end your using on the lower rear whishbone, wouldn't it be better turned 90 deg ? or have I got it wrong again

?

Adrian

cheers Ade,

rod ends are that way round because they're not very strong (relatively) in the direction of the "eye bolt". There's almost no

vertical stress on this pivot, but lots in the other 2 directions. I agree at first sight you'd think of making the wishbone hinge on the axis of

the eye bolts, but this way is shed loads strionger.

Bob

Your project looks interesting...why not pop over to the mid-engine section and tell us about it...

Cheers