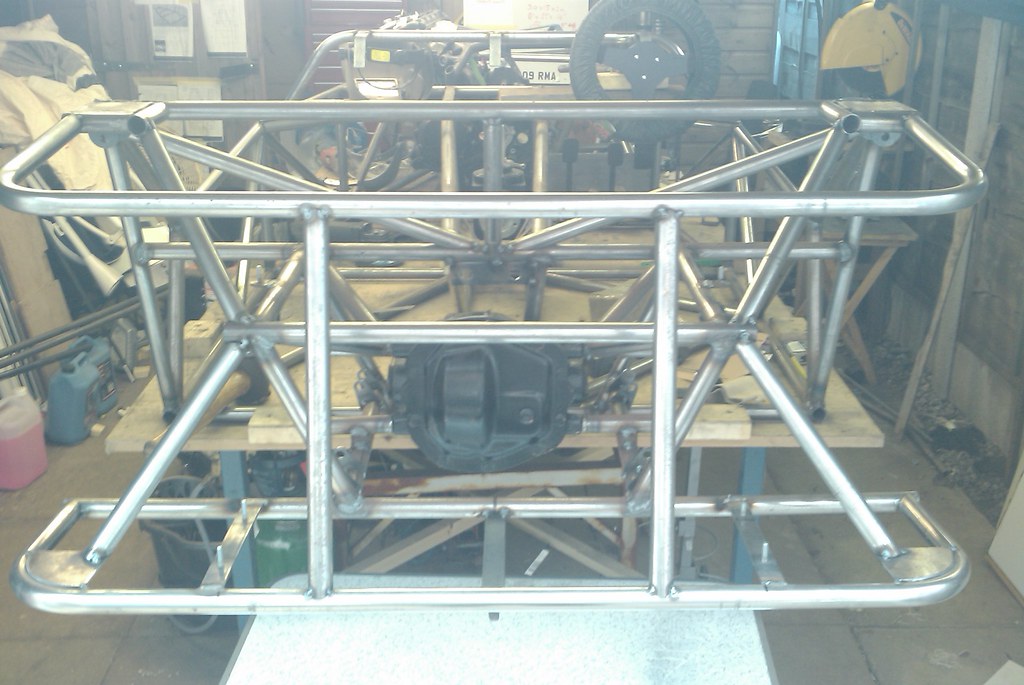

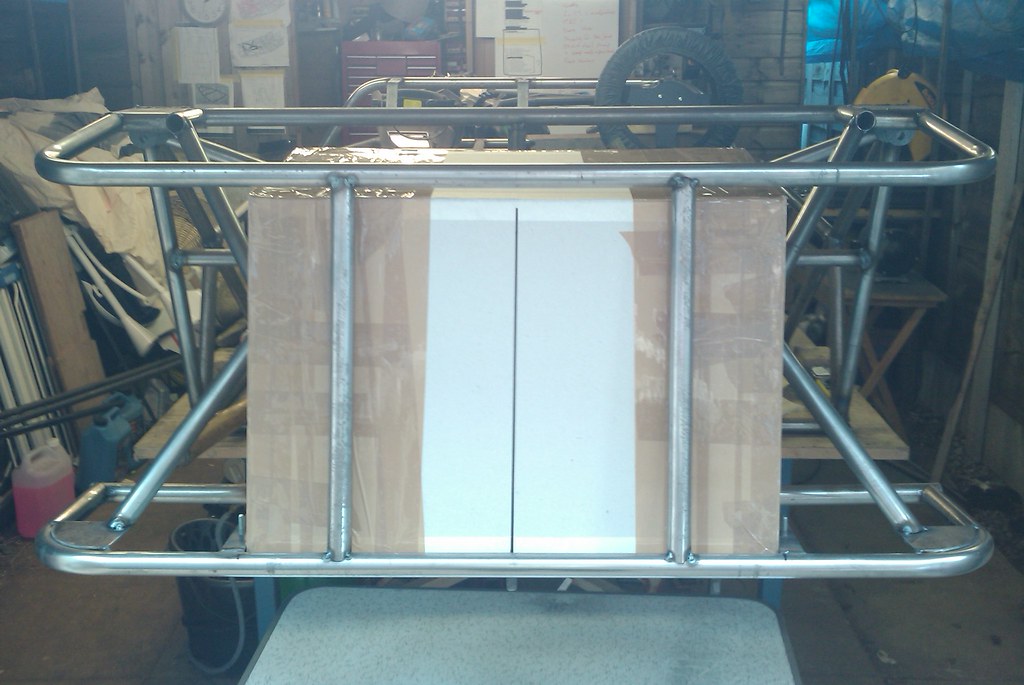

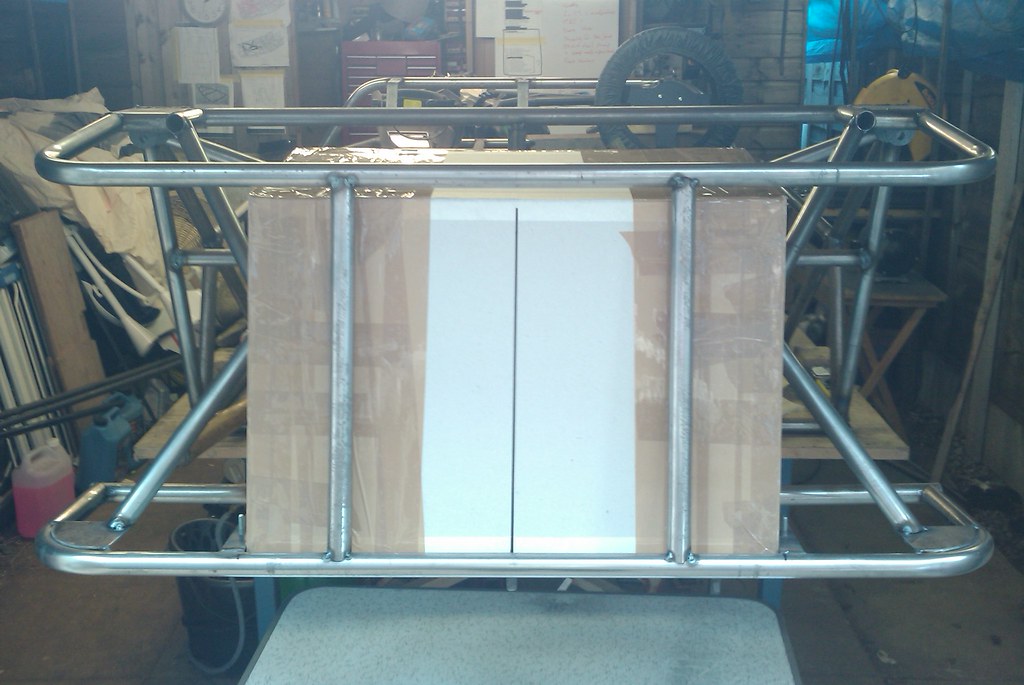

obviously it's not finished yet, so I'll be adding some more pics over the next couple weeks! (I've not done much on it in the last fortnight as I've been a tad busy around the house!)

obviously it's not finished yet, so I'll be adding some more pics over the next couple weeks! (I've not done much on it in the last

fortnight as I've been a tad busy around the house!)

Awesome progress mate, did you bend the big tubes? What size were they and how did they go?

Holy crap thats alot of photos

Good work there Steve

ps how long did it take you to write that post with all those pics?

i tell you what i'm glad you resized them to fit the page!!

well done...............keep it up...............you'll be finished in no time

quality work there

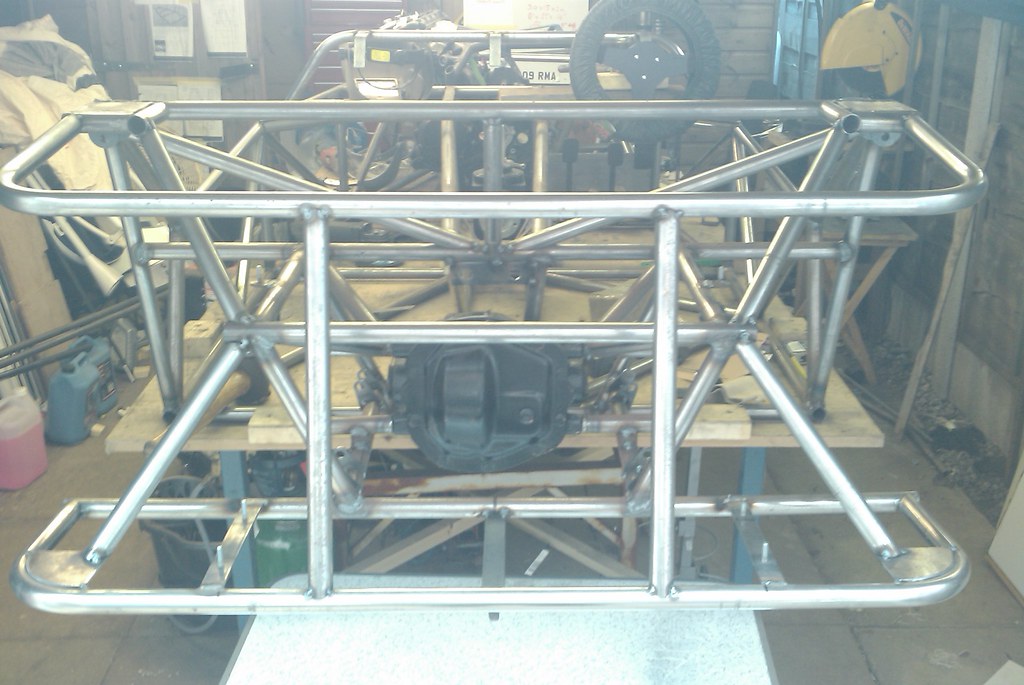

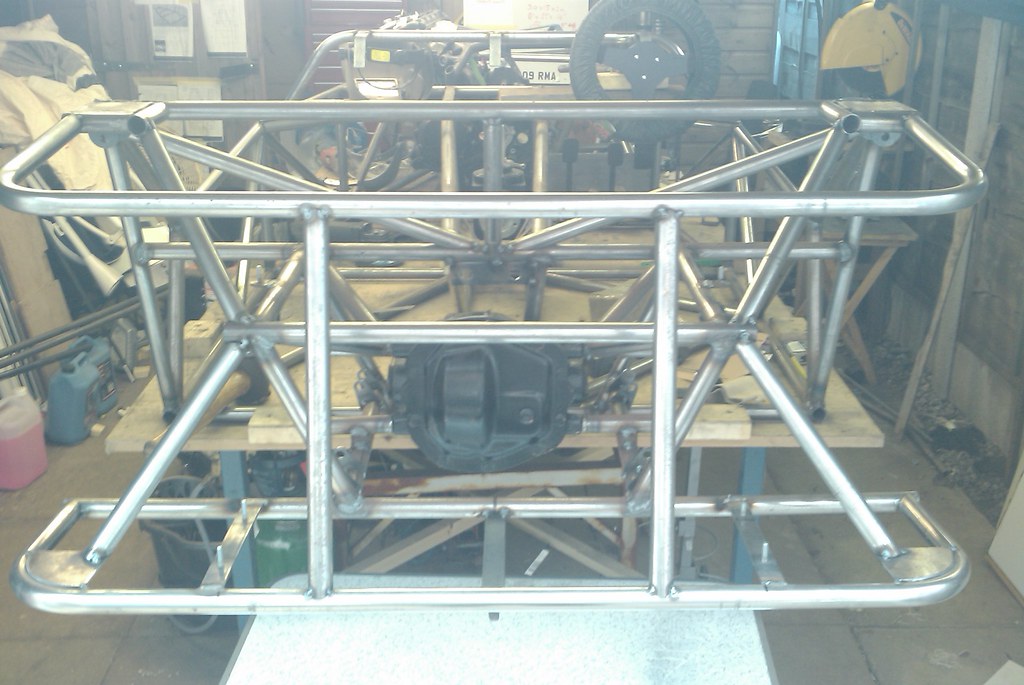

superb that mate, those side tubes are a bit like my MK Midi. I like the home made garage coming off the fence!

Bet that tank will leak.

quote:

Originally posted by fesycresy

Bet that tank will leak.

It's all right I suppose?

Pants

Looks cr*p

nice steve - was checking your site every now and then to see if you'd done more - glad work had been going on, on the QT.

Did anyone else do a little mini gasp when they saw that AMAZIN rad and oil cooler?

Just me then....

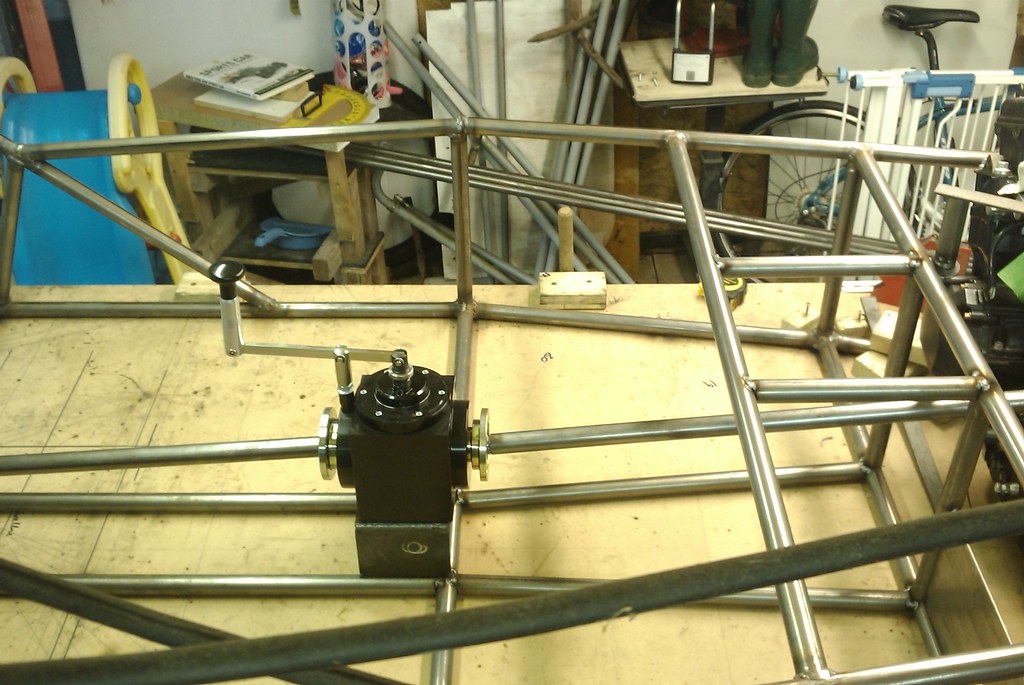

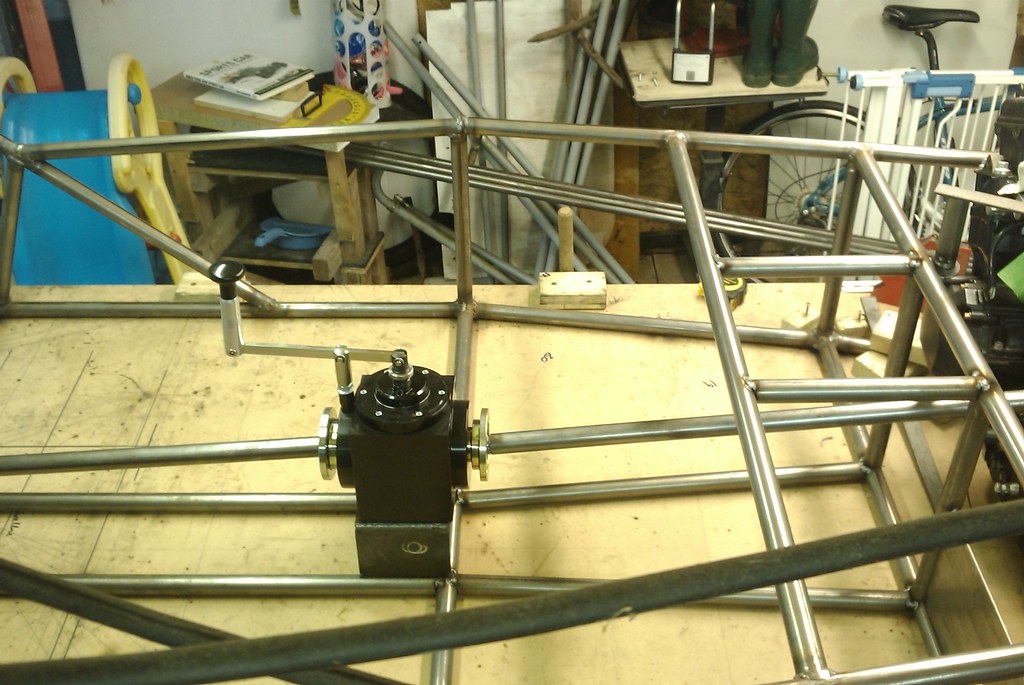

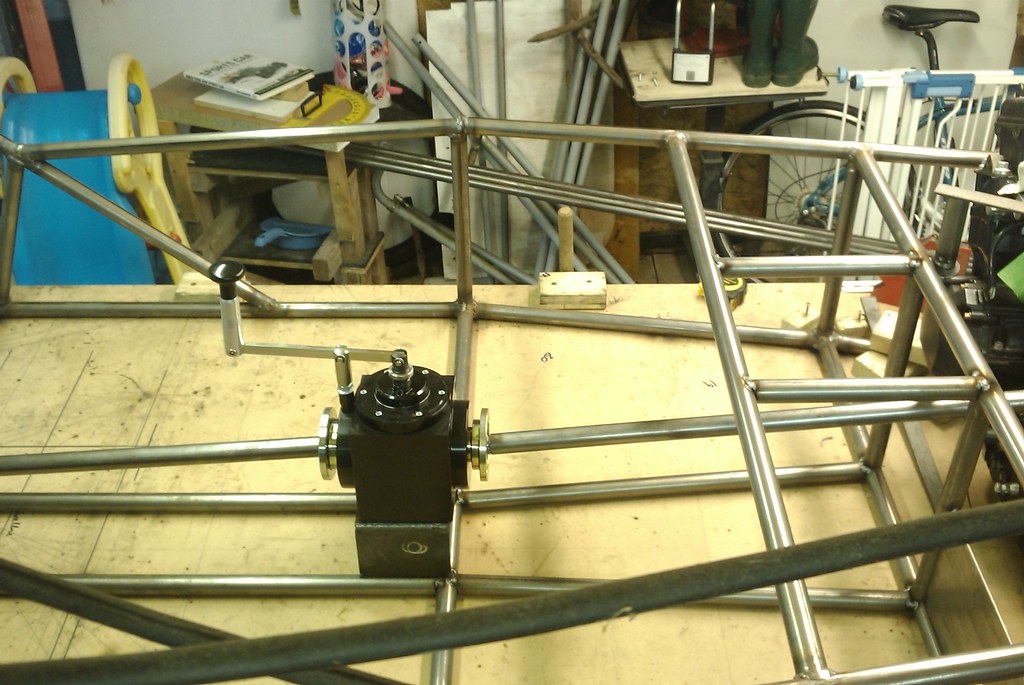

That steering column looks familiar, are you thinking of making a ball raced paddle shift on that??

BTW whats the resonant frequency of teeth??

I hope its not the same as 11,000 rpm on a ZX10

wow. to me that level of construction is mind boggling.

Looks like you've found something to to do with all those shopping trolleys you keep borrowing

Keep up the good work sparrow, will see you when i get back from my cruise mate, oh and theres a little something in the post for you  .

.

ps look after the mrs and little joe  .

.

Big Joe

Guess I'm the first to rain on the parade.

Will the suspension brackets be reinforced? Welding flat brackets onto round tubes will lead to grief. My brother's Locost had brackets like

that, cantilevered off the sides of the tubes, and one wheel broke off because of it. Examining the opposite side showed that bracket was cracked,

too, almost all the way through. See pics below... the last one is the most damning - caught in the act of failing! For a round tube chassis

it'll fail much quicker.

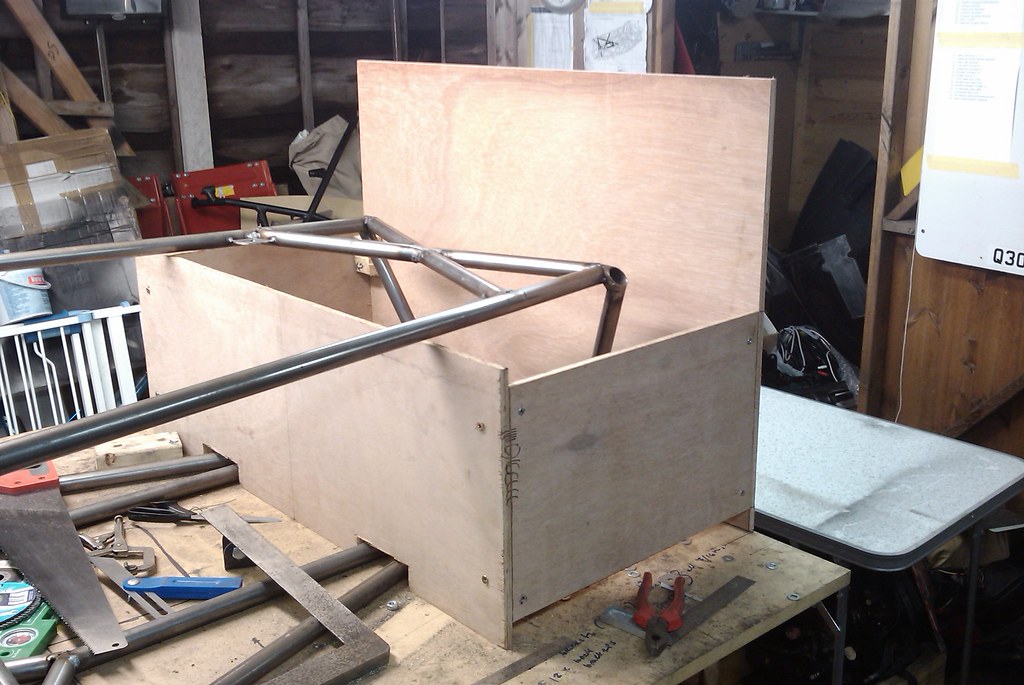

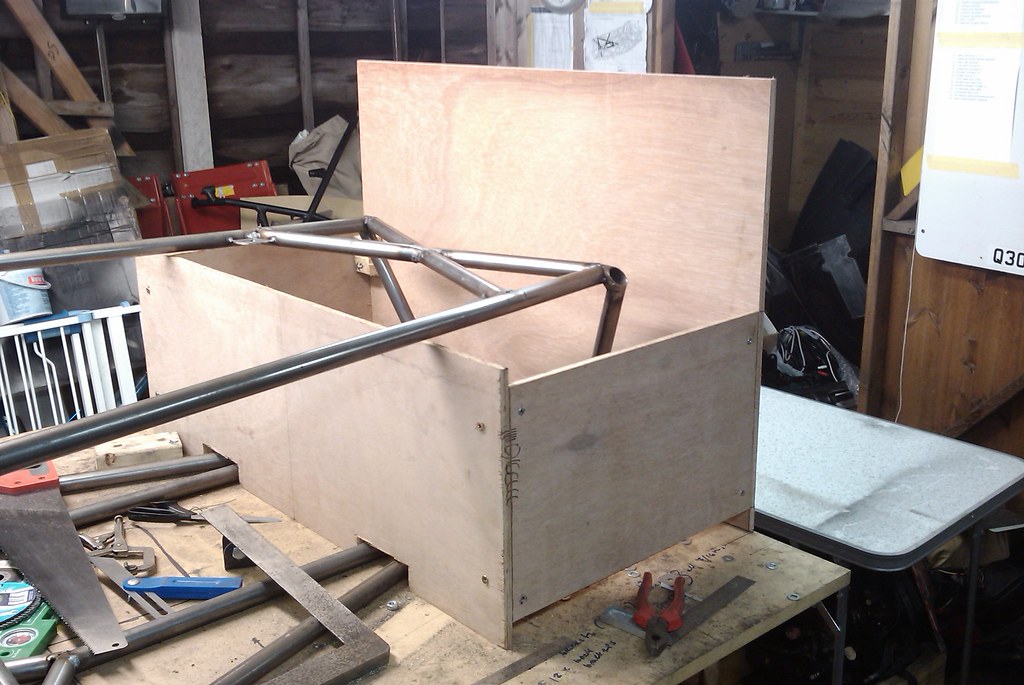

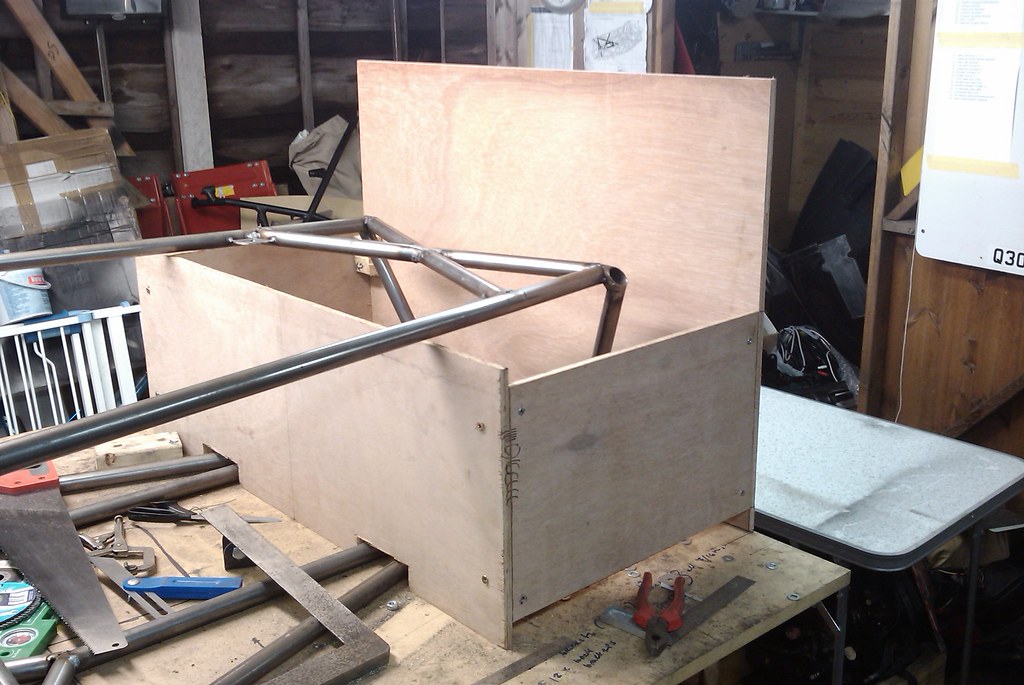

On the fuel tank, do no rigidly mount it. In any sort of accident the tank must be free to move around on its own. If the chassis gets slightly bent

it can rip the mounting tabs out of the tank, leaving a big hole.

[Edited on 3/30/10 by kb58]

Gussets aplenty yet to be installed. As for the tank.... well, its a good point but lots of cars have hard mounted tanks and I've seen straps

pierce tanks as well....

Oh, Steve reads your stuff Kurt so knows about the bracket issues.

Great looking work, Sir!

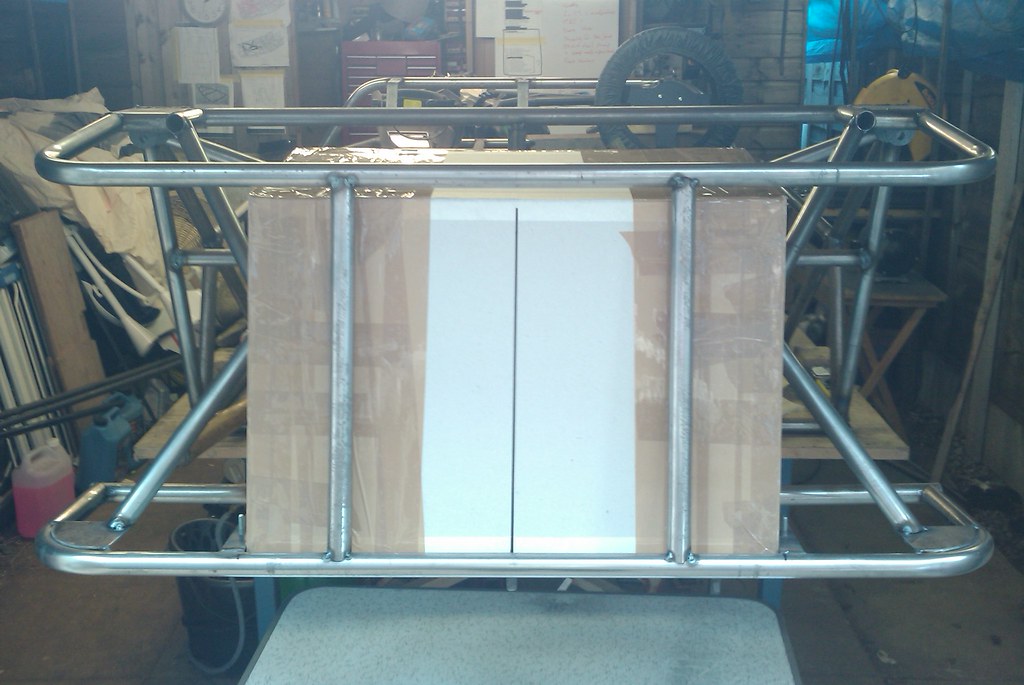

Kurt makes a good point about the bracket attachment, but overall, a very quality build. I especially like the "spider" bit that fits on

the nubs at the corners and extends over the top of the frame. Good idea, well executed!

Keep up the good work!

JD Kemp

Not bad I suppose. What did you do in the aftermoon?

Yours grumpily (after about 3 months getting 1/5 of that done)

Hugh

What are you doing about an air box??

Have you seen his airbox description/pics?

quote:

Originally posted by Steve Hignett

obviously it's not finished yet, so I'll be adding some more pics over the next couple weeks! (I've not done much on it in the last fortnight as I've been a tad busy around the house!)

Err...

Any welds that were more than just a tack weld, were ground down and rewelded by a VERY good welder.

Considering the car has only ever seen very hard track oriented miles, and it's been owned by several members of this forum, I'm assuming

that the welds held up well...

But, we all know what "assume" means.

quote:

Originally posted by Steve Hignett

Err...

Any welds that were more than just a tack weld, were ground down and rewelded by a VERY good welder.

Considering the car has only ever seen very hard track oriented miles, and it's been owned by several members of this forum, I'm assuming that the welds held up well...

But, we all know what "assume" means.

assume lol

assume lol

Digging up a ten year old thread to trash talk someone's work just makes you look like a bell end. All I see in the pictures is a lot of tack

welds, that Steve is saying got finished properly.

quote:

Originally posted by Szczebrzeszyn

quote:

Originally posted by Steve Hignett

Err...

Any welds that were more than just a tack weld, were ground down and rewelded by a VERY good welder.

Considering the car has only ever seen very hard track oriented miles, and it's been owned by several members of this forum, I'm assuming that the welds held up well...

But, we all know what "assume" means.

Fk knows what i did to include all the pictures in my reply. Im new here >_< haha! Was looking through some of the pictures and christ almighty some of the welds dont look the best and some are porous. If i went into work tomorrow morning and welded like that, i probably wouldnt have a job to go back to in the new year lol. Very good welder doesn't stand for nout if youre not certified or if you can run a straight bead. Just saying.

If the car has been driven moderately should be ok, but doubtful..... Make an ass out of u and meassume lol

quote:

Originally posted by Szczebrzeszyn

quote:

Originally posted by Steve Hignett

Err...

Any welds that were more than just a tack weld, were ground down and rewelded by a VERY good welder.

Considering the car has only ever seen very hard track oriented miles, and it's been owned by several members of this forum, I'm assuming that the welds held up well...

But, we all know what "assume" means.

Fk knows what i did to include all the pictures in my reply. Im new here >_< haha! Was looking through some of the pictures and christ almighty some of the welds dont look the best and some are porous. If i went into work tomorrow morning and welded like that, i probably wouldnt have a job to go back to in the new year lol. Very good welder doesn't stand for nout if youre not certified or if you can run a straight bead. Just saying.

If the car has been driven moderately should be ok, but doubtful..... Make an ass out of u and meassume lol

Cheers Joel...

Was not expecting those sorts of comments after such a length of time!!! Bell end just about sums it up..

quote:

Originally posted by JoelP

Digging up a ten year old thread to trash talk someone's work just makes you look like a bell end. All I see in the pictures is a lot of tack welds, that Steve is saying got finished properly.

quote:

Originally posted by Szczebrzeszyn

quote:

Originally posted by Steve Hignett

Err...

Any welds that were more than just a tack weld, were ground down and rewelded by a VERY good welder.

Considering the car has only ever seen very hard track oriented miles, and it's been owned by several members of this forum, I'm assuming that the welds held up well...

But, we all know what "assume" means.

Fk knows what i did to include all the pictures in my reply. Im new here >_< haha! Was looking through some of the pictures and christ almighty some of the welds dont look the best and some are porous. If i went into work tomorrow morning and welded like that, i probably wouldnt have a job to go back to in the new year lol. Very good welder doesn't stand for nout if youre not certified or if you can run a straight bead. Just saying.

If the car has been driven moderately should be ok, but doubtful..... Make an ass out of u and meassume lol

Well said Steve, and Happy Christmas!