blakep82

|

| posted on 24/3/08 at 03:18 PM |

|

|

ecotec to type 9 hydraulic clutch

i've got a 2 litre ecotec, and i'm ready to get me a bellhousing from yukspeed. now my chassis is already built for hydraulic clutch, but

i would rather spend the money on doing a hydraulic clutch rather than modify pedals and chassis for cable clutch

what do i need? is it possible to have a slave cylinder operate the clutch arm, so the pedals and chassis are unmodified? or do i need hydraulic

release bearings and stuff?

who else has already done this? any pics?

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

|

|

r1_pete

|

| posted on 24/3/08 at 03:23 PM |

|

|

I've just bought a wilwood 'pull' slave cylider to actuate the MT75 arm, will let you know how I get on..

One of these:

[Edited on 24/3/08 by r1_pete]

Rescued attachment wilwod.jpg

|

|

|

blakep82

|

| posted on 24/3/08 at 03:26 PM |

|

|

yeah, just been looking at those. is your intention to have the operate the clutch fork which is normally cable opterated? because i think you get

hydraulic release bearings, which i guess is the normal way. but a cable hydraulic hybrid effort looks simpler! might have to take abart the hydraulic

clutch from my old gearbox to see how that works

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

blakep82

|

| posted on 24/3/08 at 03:27 PM |

|

|

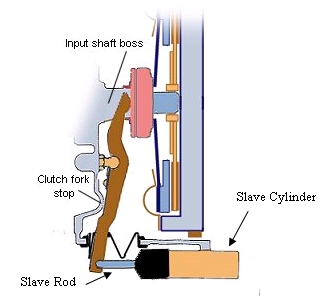

hmm, this is what i was thinking

rather than one of these

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

Werner Van Loock

|

| posted on 24/3/08 at 03:48 PM |

|

|

first picture is not going to work as the T9 has the pivot point at the end of the arm ie past the thrust bearing so needing a pull slave cylinder as

pete shows.

cleanest option though is the concentric hydraulic trust bearing you're whowing in picture 2.

Read more here

http://www.clubstylus.be

|

|

|

blakep82

|

| posted on 24/3/08 at 04:02 PM |

|

|

ah, i see. i the picture was just demonstrating the slave operating the arm which is normally cable operated, rather that the hydraulic bearing.

i know the hydraulic bearing would be neater, but i think finding the right one could be difficult with the clutch being made of a mashup of different

manufactures. i've asked this before, but does anyone know what clutch parts i need. people tend to say, well, i think its this.

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

r1_pete

|

| posted on 24/3/08 at 05:21 PM |

|

|

Yes I'm going to use it to pull the standard arm.

Burtons do all the bits for a T9 concentric, but not the MT75, but the ££££'s add up.

As for the clutch, I've re-drilled the flywheel and used the clutch which matches the gearbox i.e. 2.0 DOHC siera in my case.

[Edited on 24/3/08 by r1_pete]

|

|

|

blakep82

|

| posted on 24/3/08 at 06:24 PM |

|

|

so is a 'hydraulic nose' all i'd need? because it could be cheaper than a pulling slave cylinder and the arm, but i know these

things have a habit of not being so easy

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

Werner Van Loock

|

| posted on 24/3/08 at 08:56 PM |

|

|

hydraulic nose and probably a spacer, if you have a lathe, then that spacer can be made by yourself.

http://www.clubstylus.be

|

|

|

jacko

|

| posted on 24/3/08 at 08:57 PM |

|

|

Just a idea how about a old mini slave cylinder

|

|

|

blakep82

|

| posted on 24/3/08 at 09:46 PM |

|

|

quote:

Originally posted by Werner Van Loock

hydraulic nose and probably a spacer, if you have a lathe, then that spacer can be made by yourself.

oh yeah, and the spacer, i didn't know if the 'nose' was the actual slave cylinder you see. i don't have a lathe, but i do

know the guy at the engineering shop very well.

£79 for the 'hydraulic nose' and whatever for a spacer seems better than £79 for a wilwood slave cylinder (can't find one on

ebay...) and £35 for the arm, and whatever for the release bearing and all the fitting kids etc...

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

NS Dev

|

| posted on 25/3/08 at 10:46 PM |

|

|

I made my concentric release setup (type 9 to XE so similar to yours) for around £50.

saab 900 "classic" (eg. 1987 at your local motor factors) concentric slave cyl and std saab release bearing, fitted to machined ally spacer

made from scrap ally.

cr1

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

NS Dev

|

| posted on 25/3/08 at 10:53 PM |

|

|

more detail:

the spacer is fitted on top of the std cast iron gearbox "trumpet" section, with the tube machined off and then thinned down so it just

acts to retain the front bearing (saved machining the bearing retaining bit into the ally)

The ally bit is then machined to fit over a step machined into the cast iron bit so ti all stays concentric, then its held on with the same 4 bolts

that hold the cast iron trumpet on as std, just much longer ones, and the heads of them(they are capheads obviously) sit in counterbores in the

ally.

This allows the saab cylinder to sit wherever it likes as it will certainly interfere with one of the 4 fixing bolts that hold the spacer on.

There's a small recess machined into the front of the ally coinciding with a register on the back of the saab cylinder, again this all keeps it

concentric.

Three bolts tapped straight into the ally spacer then hold the cylinder on.

the cylinders are £40 ish new and the bearing a tenner or so.

[Edited on 25/3/08 by NS Dev]

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

blakep82

|

| posted on 25/3/08 at 11:17 PM |

|

|

^ good work! although i've not got a very good engineering brain  only today did i understand how a clutch works only today did i understand how a clutch works

i'd be looking for a simple buy and bolt on solution. even if it does involve spending a bit more

did you menttion before i'd be needing a clutch plate from a 2.3 diesel sierra?

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

NS Dev

|

| posted on 26/3/08 at 05:55 PM |

|

|

that one will do the trick, combined with the std vauxhall cover (or it does on the XE anyway so guess the ecotec is the same)

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

blakep82

|

| posted on 26/3/08 at 06:00 PM |

|

|

i assume it's the same.. don't know really. I took my engine to be rebuilt last night so its not here to check, but i was asking him about

the clutch, he said as long as the clutch plate fits the spline on the gearbox and is roughly the same size as the vauxhall plate (it can be about

10mm bigger) then it should be fine. i'll take the plate to the motor factors tomorrow and see what we can do.

is the type 9 spline 1" x 23 splines?

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

Davg

|

| posted on 26/3/08 at 08:08 PM |

|

|

And you know a man who has a new 2.3 genuine ford clutch kit!

------------------------------------------------------------------------

|

|

|

blakep82

|

| posted on 26/3/08 at 08:14 PM |

|

|

quote:

Originally posted by Davg

And you know a man who has a new 2.3 genuine ford clutch kit!

do you?!

i either didn't know you did, or if you told me, i have a crap memory (my vote's on my crap memory...  ) )

how much would you be looking at?

also, if the diff flange is the same on the capri atlas axle as on the sierra, mihgt be interested in a prop shaft if you have one?

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

Davg

|

| posted on 26/3/08 at 08:52 PM |

|

|

Blake don't know if atlas & sierra flanges are the same or not, someone may confirm, alternative template or measure the pcd of the atlas

& check against the sierra. There might just be a 2 piece job in the cave. Clutch plate & cover £30. Cheers D

------------------------------------------------------------------------

|

|

|

NS Dev

|

| posted on 26/3/08 at 09:25 PM |

|

|

atlas and sierra flanges are the same.

yep type 9 shaft is 1" 23 spline

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

NS Dev

|

| posted on 26/3/08 at 09:27 PM |

|

|

I have a 1 piece large diameter tube type 9 to atlas/sierra diff prop, done under 100 miles from new, £75 plus post, can confirm length but it was

approx mk2 escy length (was in rwd pug 205 which was slightly longer wheelbase than a mk 2 as i stretched it a tad)

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

blakep82

|

| posted on 26/3/08 at 09:38 PM |

|

|

^ cheers lads! i don't know the length of prop shaft i need yet, and won't know til i get my engine back really  i'm only looking

for the ends really i'm only looking

for the ends really

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|