twybrow

|

| posted on 20/11/07 at 11:37 AM |

|

|

Propshaft angles

Description

Firstly, sorry about the pic, for some reason I cant seem to crop it and upload!

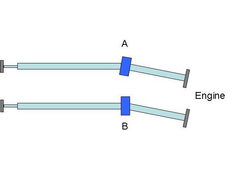

Is it ok to have the output from the bike gearbox at an angle to the axle flange? If so, what orientation does the bearing sit in? Do most BEC props

pass through an anlge like this, or do other engines fit squarely in the chassis (as opposed to mine which sits paralell to the top diaganol that cuts

across the right hand side of the engine bay).

I am concerned that although the angle is relatively small (~5deg), it may cause me issues. Any comments?

|

|

|

|

|

tks

|

| posted on 20/11/07 at 11:49 AM |

|

|

yeah,

basicly what you want in prop shaft is that the angle speeds egual them selves.

that will result in no vibrations.

sow best practise is to have the diff flange parallel with the engine flange.

tks

The above comments are always meant to be from the above persons perspective.

|

|

|

Guinness

|

| posted on 20/11/07 at 12:19 PM |

|

|

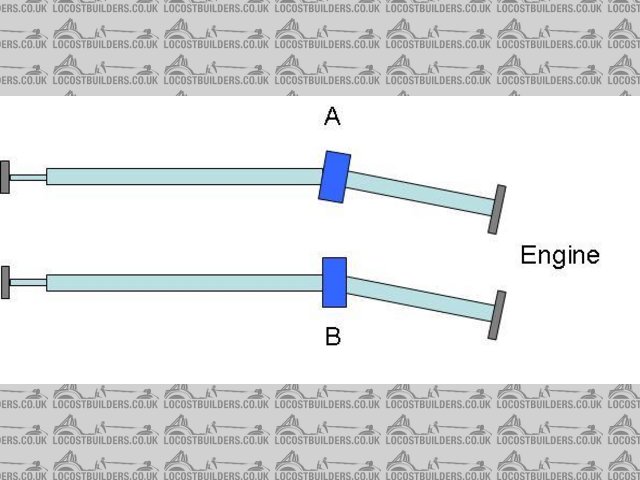

This is how my prop shaft is installed in the Indy.

Mike Prop Shaft

The engine sits square, rather than at an angle.

It has three uj's in it, and the bearing supports the middle section. Looking at the way mine is installed, I can't see any problem with

having the engine at an angle to the diff. The three uj's have been fine like this for 3,500 miles so far!

Cheers

Mike

|

|

|

dhutch

|

| posted on 20/11/07 at 05:58 PM |

|

|

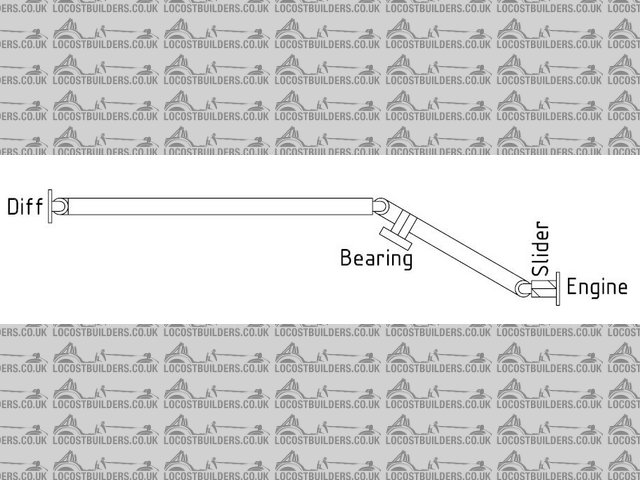

As i understand it, theres no reason why you cant do that, but you need to use a cv joint not a uj.

If you are using uj's, then as the others have said, you need to have the two flanges parralell.

- Ie, have two joints, and have the engine off center, but square.

- Then the pair of uj's are placed 90degrees out of phase, and cancel each other out.

- The engine and diff then turn at the same (constant) velocity. With just the center shaft (which is thin and low interia) moving at a non constant

velosity.

However, with a CV joint you can the flanges at an angle, and as many joints as you like, and have both the engine and diff going a constant revs.

Because thats what they do.

- Just dont take the cv joints past there max angle.

Daniel

|

|

|

TGR-ECOSSE

|

| posted on 20/11/07 at 07:45 PM |

|

|

There was a similar question not that long ago here that might help.

|

|

|

twybrow

|

| posted on 21/11/07 at 10:36 AM |

|

|

I just spoke to Bailey Morris, who assured me it would not be an issue, as long as the misalignment is less than 5 degrees. They say in an ideal word

aim for them to be parallel, but in the Locost world, it is unlikely to have s ignificant effect. His comment was it is likely to reduce the U/J life

by 10% (from 20,000 miles to say 17-18k). In a BEC i think that will be plenty!

|

|

|