DarrenW

|

| posted on 28/9/07 at 03:13 PM |

|

|

Custom Catch Tank design - update 8th Oct.

How have you done your catch tanks? Any fancy baffles inside?

Mine is still causing bother. Ive attached rough sketch. Hope it makes sense.

Original design was simple 1 litre ali tank. 2 inlets at the top (only entering tank by 10mm max). Breather outlet in the top. i was convinced the

vapours were entering such that the oulet was allowing them to escape immediately into the breather. This constantly got full of oil and made a

mess.

I then cut the top off and added a baffle. The theory being the inlet would hit the baffle and at least run to the bottom. I added a drain back to the

block (i know this si an area of discussion but its good oil in the tank). I think i may have the baffle too low and the oil entering is splashing

about and spraying all over making a mess again. Net result - no better off.

Its doing my head in now. i could shorten the baffle and make a vented top for the tank but id rather have less oil getting to the tank.

Oil pressure is great (60 - 70psi hot is normal - average 4.5bar). Engine runs great. I dont suspect any problems with the engine at all (in fact this

si a newer block fitted last winter and the old one was the same). Im using Cortina style crankcase breather. Oil cap is std vented with mesh inside,

piped to the tank.

When i was using the original tank i used to get oil out of the dipstick yube when it was getting full, i dont get this snymore (some weeping from

base of tube but nothing worrying).

As most people know ive researched breathing to death but running out of ideas.

Its a Pinto on bike carbs with Megajolt.

Any ideas? Maybe the design of the catch tank is just wrong and different design is needed. I always thought it would have been better if the 2 inlets

ran lower inside rather than just entering at the top, but i hoped baffle would simulate that.

Im just a tad sick of cleaning the oil up now.

[Edited on 2/10/07 by DarrenW]

[Edited on 8/10/07 by DarrenW]

|

|

|

|

|

DarrenW

|

| posted on 28/9/07 at 03:17 PM |

|

|

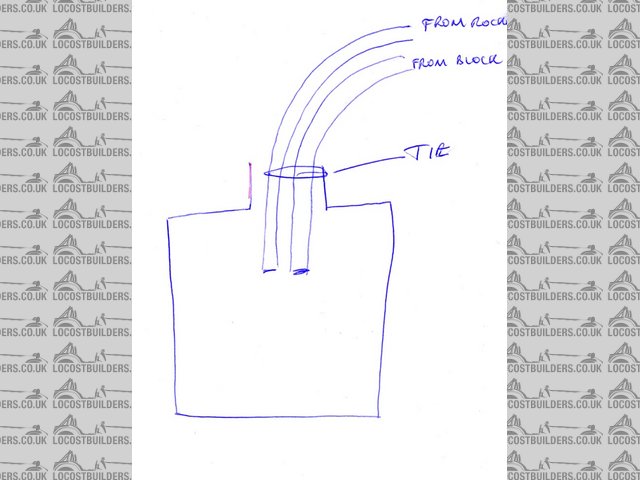

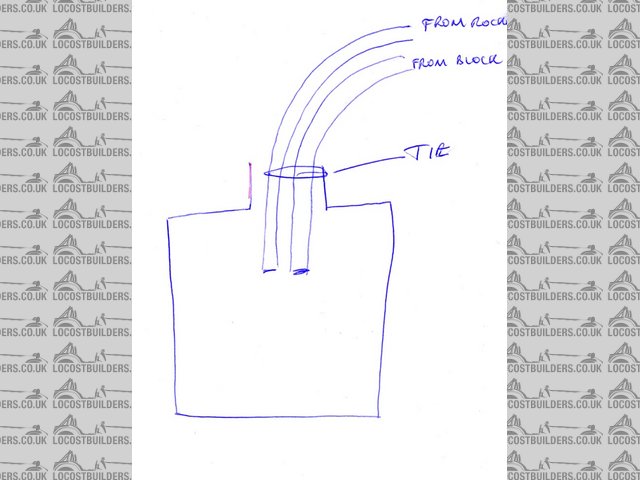

Here is a pic of the modded tank showing the internal baffle (drain back to tank not shown on this pic).

What im really trying to find out from those with no issues on a Pinto is whats the main difference between your set up and mine. Im sure there will

be a clue there somewhere.

Maybe i need a bottle that is deeper (ie 1.5l pop bottle for a trial) in which i can fit the 2 pipes in directly near the bottom of it and not use the

top which is at least quite high, smallish diameter and tapered.

[Edited on 28/9/07 by DarrenW]

Rescued attachment 19072007138.jpg

|

|

|

designer

|

| posted on 28/9/07 at 03:23 PM |

|

|

There is nothing special about swirl pot design.

The only requirement is that the inlet enters the pot tangentialy, hence the name swirl pot.

Liquid entering then swirls around the side of the pot.

No baffles are required.

|

|

|

designer

|

| posted on 28/9/07 at 03:24 PM |

|

|

Oh, and the inlet should be at the top, exit at the bottom.

|

|

|

RazMan

|

| posted on 28/9/07 at 03:33 PM |

|

|

Err a swirl pot id different to a catch tank isn't it?

My catch tank is simply a 99p alloy drinks bottle with inlet on the side and filter on the top. After 10k miles there is just a dribble in the bottom

of the tank. I noticed I get some water vapour boiling off sometimes but no oil.

[Edited on 28-9-07 by RazMan]

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

nib1980

|

| posted on 28/9/07 at 03:44 PM |

|

|

I made mine from a used small welding gas bottle, dead easy, and no problems yet

|

|

|

DarrenW

|

| posted on 28/9/07 at 03:52 PM |

|

|

What is the configuration of the pipes inside Nib??

http://www.locostbuilders.co.uk/photos.php?action=showphoto&photo=catch%20tank.gif

The thing that confuses me the most is how some people have no problems and mine, very similar to the norm from what ive researched, has loads of

bother.

One difference is the rocker cover. Mine is std Ford, no mods (i didnt have to move the filler neck). Dont know if this makes a difference or not.

Troubles in the last week could be attributed to overfilling with oil, but even at a stable level its not great (i have to run between middle and

lower mark, its currently between middle and upper mark on dipstick).

I just need to put my finger on the main big difference and then i should be closer to the solution. Some pics of yours may help if you can oblige

(anyone that is).

Ive also tried bringing the pipe up from crankcase breather at near vertical and teeing into the line from oil filler cap to catch tank - no

difference. i havent yet tried sealing off the filler cap pipe - would this help?

[Edited on 28/9/07 by DarrenW]

|

|

|

nib1980

|

| posted on 28/9/07 at 04:03 PM |

|

|

Top hose is inlet from breather, the other two visible are connected with clear tube as a sight level indicator, the other tube not visible on the top

goes to a small filter to allow breathing of the air

hope that helps

|

|

|

DarrenW

|

| posted on 28/9/07 at 04:03 PM |

|

|

Thanks Nitram, that was kind of my thinking also but with nothing to confirm it. iwas hoping the baffle would simulate it but i may have the base too

close to the bottom of the tank (ie too close to the top of the residual oil level causing the splatter). It looks OK when car is stationary but of

course the oil will move around on the road.

Do you think something like third sketch titled Idea would be better? Basically a taller bottle, 2 inlets entering at top but going further down,

vented around the neck of the bottle??

[Edited on 28/9/07 by DarrenW]

|

|

|

BenB

|

| posted on 28/9/07 at 04:08 PM |

|

|

Is there a reason why you need such a big catch tank?

On most engines you only get a small amount of oil (vapour) coming out of breather pipes and unless it's for racing you can get away with a

breather filter. It's more for tracks that you need a catch tank (to avoid getting oil on the track).

Sounds like there's some pressurisation going on there to force the oil out...

Doesn't sound right to me but I'm a BEC man....

|

|

|

nitram38

|

| posted on 28/9/07 at 04:30 PM |

|

|

I think that I have sussed your problem.

Both your breather hoses should enter from the top of your tank.

Both relieve crank case pressure.

If the block breather is at the bottom of your tank, it is blowing any oil that collects, out.

You should not let oil from your catch tank to drain back to your sump via your breather anyway.

You should throw it away and top up with fresh.

I have used simple tin cans with the breathers just dropped through the top of the can and tied so that they do not sit on the bottom in the oil.

I think for racing you need at least a 1 ltr tank but some regs might specify bigger.

Here is a simple catch tank that you can adapt to your own:

Description

[Edited on 28/9/2007 by nitram38]

|

|

|

DarrenW

|

| posted on 28/9/07 at 05:04 PM |

|

|

Nitram,

Ive just been talking this through with Mookaloid. Looks like you may have hit the nail on the head.

Both inlets enter at the top. The baffle sort of converts them to bottom feed but problem no. 1 is the baffle is too long.

I understand about draining back to engine, but in my case it is good oil collecting in the tank. I think my 2 main issues are;

1. The drain i have fitted enters the engine via a modded oil gallery plug. This is basically part of the crankcase and subject to the same pressures

that the cortina trap sees. On one hand it does allow oil to drain back but mainly when engine is off. When running, crankcase pressures can also

force the draining oil back up = splatter and mess - ie its acting as a combined breather and drain which in hindsight isnt a good plan.

2. The top of the catch tank is open / too large.

I dont think blocking the drain off will totally solve my problem as for some reason my engine circulates more than average oil (and this is the 2nd

engine to do it). However if it were to drain below oil level in the sump then the crankcase pressures wouldnt try and vacate through it.

Im now planning to shorten the baffle and maybe try some foam / sponge at half way point or try a new bottle as in your pic (this is what i tried to

show in pic 3 of the file but not as good as your sketch). I know Andy D uses a similar bottle to your sketch and gets little oil in it. Im hoping

that a bottle top(eg bike water bottle / small flask), being tapered and smaller entry, will suffice being left open.

My other theory is that my shortened sump design may not be optimal WRT baffles etc. Maybe the oil is being allowed to move around too much and being

closerto the crank could be getting whipped up - this is probs why its sensitive to overfilling.

Thanks for the suggestions - giving me something to think about for the redesign. It has also been suggested that i try clear tube so i can see where

the oil is coming from.

|

|

|

DarrenW

|

| posted on 28/9/07 at 05:12 PM |

|

|

The only downer to the simple bottle idea is that ive tred something similar before a recent track day - using beer can. It still filled and made a

mess albeit before i sourced the cortina trap (using sierra trap with valve removed but small bore outlet) and i cant be sure the pipe wasnt too low

down.

|

|

|

nitram38

|

| posted on 28/9/07 at 05:36 PM |

|

|

Have you removed the little box from the side of the block breather?

You should run your hose straight into the block and remove the box.

It contains gauze and a little flap valve.

If the flap valve is left in this causes a build up of pressure.

Unless your catch tank is very low (lower than the block outlet), you should not get more than 0.5mm of oil in the catch tank.

You just need a pipe from your rocker cover cap and one from the block with no drain.

You can even T the pipes together so that only one pipe goes into the catch tank.

Your problem is probably the location of the extra drain, which is forcing oil into your catch tank.

The only oil in there should be only condensed oil from the vapor from both breather hoses.

[Edited on 28/9/2007 by nitram38]

|

|

|

mark chandler

|

| posted on 28/9/07 at 07:07 PM |

|

|

How about sticking a load of aluminium swarf in it, the stuff you buy from sainsburys to clean pots.

The vapour will hit the swarf, form into droplets and drip to the bottom, at present you have a can full of airborne oil fumes.

Regards Mark

|

|

|

MkIndy7

|

| posted on 28/9/07 at 07:59 PM |

|

|

Trying 2 seperate tanks for the Crank case and rocker/filler cap is also worth a try even just temporary.

We had the Crank and Rocker breathers coming in at 180 deg from each other and 1 was basically pressurising the other! oil everywhere!

We've had very little in the bottle itself that wasn't watery... but when its not working it comes out just about everywhere! or gets

blown about in the wind and appears to.

|

|

|

jacko

|

| posted on 28/9/07 at 08:03 PM |

|

|

Dam Dam Dam  i have just fitted a return pipe back to the sump and not tryed it yet was that a waste of time then or can i fit a one way valve in

the pipe i have just fitted a return pipe back to the sump and not tryed it yet was that a waste of time then or can i fit a one way valve in

the pipe

Jacko

|

|

|

MkIndy7

|

| posted on 28/9/07 at 08:16 PM |

|

|

*coughs* coming from Mr I don't have breathing problems

The return tapping to the sump must only be on the 205 block cos I can't find it on our 200 block.

I'm sure its been done by somebody on here... hopefully they'll be along to tell you shortly how its done.

|

|

|

jacko

|

| posted on 28/9/07 at 08:21 PM |

|

|

Hi Mark [ Mookaloid ] has a return to the sump , a pipe from the oil filler top and a pipe from the side of the block and it works ok as far as i

know

Jacko

|

|

|

nitram38

|

| posted on 28/9/07 at 08:39 PM |

|

|

What I don't understand is why you would want to return oil to the sump after it has been heated to a vapor?

On your original engine, these oil vapors are fed into the inlet to be burnt.

By returning what is basically knackered oil to your sump, you are destroying/contaminating the good oil that is left in the sump.

[Edited on 28/9/2007 by nitram38]

|

|

|

DarrenW

|

| posted on 28/9/07 at 09:04 PM |

|

|

Probs best not turning the post into a discussion on returning catch tank spoils to a sump, but in my experience what i have found is if the oil isnt

allowed to sit in the tank for some time then it is good oil. It is only when vapours sit their over time that it goes murky and manky. On some

peoples system the caught gunk is little more than waste and i agree - that should be chucked. There seems to be some people that get good oil thrown

into the catch tank in such a volume that you would rather not throw away unless you have shares in Kuwait, whilst others only have horrid stinky

watery vapour type spoils. This is the reason for the thread - mine are good oil

Graham - if you have fitted the drain back to the sump, ie under the oil level in sump, then you will be ok. My problem is partly that iam draining

back via an oil gallery tapping - driving hard this is a breather rather than drain point and i think it is causing splattering.

Nitram,

What do you mean by the block with flap and gauze in??

That ali swarfe looking pan scrubber stuff is a fair idea, i was wondering where i can get some open cell foam from - an old sock filter would be good

if anyone has one kicking about.

[Edited on 28/9/07 by DarrenW]

|

|

|

nitram38

|

| posted on 28/9/07 at 09:18 PM |

|

|

It's about 20 years since I rebuilt a pinto so I might have got the crossflow breather confused with it,

Whatever valve system is used on the engine, remove it.

The valves were designed to stop oil (liquid) being drawn into the inlet manifold.

You want to have a crankcase that breathes without pressure.

The original oil breather was an emissions device where air was drawn through the block to remove the oil vapour that would normally vent to the

atmosphere and instead burn it off.

On a road car it is fine to have this arrangement, but not on a modified engine or race car.

Catch tanks on race cars are compulsory to help prevent oil spills on the track if you blow a hole in a piston etc.

The fact that your oil has turned to vapour is telling you that it has be heated too much and will have lost some of it's viscosity and

therefore is not much use to your engine.

That is why I said throw it.

A normal road car would have burnt this up and you would have had to top up your oil anyway. So you are not saving anything by returning it to the

sump. All you will be doing is diluting the good oil.

|

|

|

DarrenW

|

| posted on 28/9/07 at 09:19 PM |

|

|

quote:

Originally posted by nitram38

Have you removed the little box from the side of the block breather?

You should run your hose straight into the block and remove the box.

It contains gauze and a little flap valve.

If the flap valve is left in this causes a build up of pressure.

Unless your catch tank is very low (lower than the block outlet), you should not get more than 0.5mm of oil in the catch tank.

You just need a pipe from your rocker cover cap and one from the block with no drain.

You can even T the pipes together so that only one pipe goes into the catch tank.

Your problem is probably the location of the extra drain, which is forcing oil into your catch tank.

The only oil in there should be only condensed oil from the vapor from both breather hoses.

[Edited on 28/9/2007 by nitram38]

Not sure what you mean here to be honest. My original breather was 1987 vintage sierra A PCV with 2 tiny outlets. I started by taking out the spring

plunger. Then pulled it out completely and replaced with the Cortina trap (large oblong box that i think just has an angled baffle plate inside).

Catch tank is sitting on a horizontal bit level with bottom of scuttle (highish up).

Before fitting the drain i tried Teeing the 2 pipes together and running seperate. This si why im so bothered - i keep thinking ive tried most

permutations but something must be alluding me. Im sure ive missed something simple but too close to the problem so blind.

|

|

|

2b_pablo

|

| posted on 28/9/07 at 09:26 PM |

|

|

quote:

Originally posted by nitram38

Here is a simple catch tank that you can adapt to your own:

Description

[Edited on 28/9/2007 by nitram38]

exactly the way I have mine, pipes both run to the bottom. burton vented filler cap and cortina trap.

I get a little oil coming out the dipstick but only a little.

No bother really even on track.

[Edited on 28/9/07 by 2b_pablo]

|

|

|

nitram38

|

| posted on 28/9/07 at 09:29 PM |

|

|

Just get rid of the drain and try it with the pipe from the filler cap (I am assuming that you have this) and one from the side of the block.

I would even get rid of the Cortina trap as it could be causing a blockage.

I sounds to me that your system is getting pressurized and that is forcing oil into the tank.

As the drain level is in this oil, it is then blowing it out of the tank.

If you do all of this and you are still getting oil thrown out, then do a compression test on your cylinders.

Too much pressure could be your rings are worn and you are getting excessive blow-by.

Pablo, lift the pipes off the bottom of the catch tank and then you shouldn't get any oil out of the dipstick.

If the pipes are touching the bottom, they are not breathing and it is pressurising your crankcase

[Edited on 28/9/2007 by nitram38]

|

|

|