tks

|

| posted on 29/11/06 at 09:29 PM |

|

|

CLUTCH PROBLEMS (RIGID CLUTCH)

Hi all,

i have this situ

CLICK ME

the dia meter of that thing is 60mm that means that it can only cope with 35NM.

have done the maths and i come up with 400NM in first

293NM in second

231NM in third

189NM in fourth

163NM in fifth

147NM in top gear

is it true that while accelerating in first i never cant create 400NM because i'don't have the resistance for it? i mean to be able to

generate the horses i need injecting alle the cc possible of fuel but as you now in first you will reach 10.500 rpm with 25% of throttle.. sow i cant

is this true?? Would i try to pull out a tree with the car then it could be not??

its meany when no revs no newtons..

but while making revs throttle needs to be less... etc. etc..

i now only have 35NM i guess the plastic thing will part?? or will hole the thing shear off??

if we only focus on top gear (maximum power, maximum horses, MAX SPEED etc. etc.)

i would have 147NM @8500Rpm..

is it true that if i get a clutch wich can cope with 150NM i will be fine??

or will i need one wich could cope with 250NM.. and when in third where the real power is delivered it can cope with it??

Let the talks begin!

Cheers,

Tks

The above comments are always meant to be from the above persons perspective.

|

|

|

|

|

DIY Si

|

| posted on 29/11/06 at 09:42 PM |

|

|

You can generate as much power as the engine will allow, but it's wether you have the traction to use it all. Hence why cars spin most in 1st,

less in 6th. If your calculations are correct, as soon as you boot it, that yellow thingy will rapidly fall apart. However you can still get to full

revs without using full power, if the gearing means that the power available will still allow the revs. ie in first you will get to 10,500, in 6th you

won't.

“Let your plans be dark and as impenetratable as night, and when you move, fall like a thunderbolt.”

Sun Tzu, The Art of War

My new blog: http://spritecave.blogspot.co.uk/

|

|

|

Liam

|

| posted on 30/11/06 at 12:24 AM |

|

|

I think it's perfectly feasable that in good (grippy) conditions, you could have full traction when you reach peak torque even in first gear.

Therefore the driveline could see the whole 400Nm and should be rated accordingly. What exactly is that yellow thing? Surely it can take more than

35Nm if it's designed for that type of application??

Liam

|

|

|

NS Dev

|

| posted on 30/11/06 at 08:30 AM |

|

|

Mr TKS!!!

I told you that "thing" will be ok!!!

It won't just shear off because the plastic bits are in compression.

Stop worrying and drive it!

PS I would worry more about the chain size.

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

tks

|

| posted on 30/11/06 at 09:38 AM |

|

|

mhhh

you with your chain size...

i have chain 5/8 and 9mm of pinion. thats 0,354

its industrial name will be then chain 535

not??

the pinions are masive it are plates of 9mm with.. the chain should be able to with stand 2 Tons easyly... not??

TKs

where is based that figure on then of 35NM..??

i maybe have found a way to increase it.

in fact i fill move the slave cilinder more to the block wards. (max. possible).

Doing that i will have more room to put a 70mm clutch on and thats is already twice as strong! 80NM..

Cant see wy it would survive only if torque is based on the plastic thingy..and on 1 year 24hr service... etc.

Tks

[Edited on 30/11/06 by tks]

The above comments are always meant to be from the above persons perspective.

|

|

|

macnab

|

| posted on 30/11/06 at 10:11 AM |

|

|

Oh that's what your up to...

Your only ever going to break that if you wedged your wheels with bolders and dumped the clutch. You've no weight at the back plus the diff

reduction. It'll just spin the wheels. I would just run it.

|

|

|

tks

|

| posted on 30/11/06 at 10:49 AM |

|

|

i think its impossible..

only at full BHP i can generate full torque..

in first gear you aren´t using full torque neither full bhp..

for that you need all the revs your engine can make and max fuel / air in the engine...

also you can only generate it if you have resistance..

Tks

The above comments are always meant to be from the above persons perspective.

|

|

|

tks

|

| posted on 30/11/06 at 11:10 AM |

|

|

mhh..

Chain...

the chain will be upto the job...

by far..

wy? because on the bike the sprocket turns +/- 6500 in topgear..

and the rearwheel?? there goes up the torque in the chain!!!

i still have the diff in between sow my chain only sees the torque from the engine... wich is 80NM in topgear..

Tks

The above comments are always meant to be from the above persons perspective.

|

|

|

MikeRJ

|

| posted on 30/11/06 at 03:08 PM |

|

|

quote:

Originally posted by tks

i still have the diff in between sow my chain only sees the torque from the engine... wich is 80NM in topgear..

If you chain drive is only seeing 80NM, how come the cush drive is seeing 147NM?

|

|

|

NS Dev

|

| posted on 30/11/06 at 03:11 PM |

|

|

I think it will be fine, I was only winding you up!!!

The chain will no doubt be weaker than the coupling though.

The coupling as it is now will be fine, don't worry.

I have a much bigger problem, 2 engines, both 1000cc v twins and a chain as final drive!!!

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

tks

|

| posted on 30/11/06 at 03:36 PM |

|

|

thats not a problem!!

Just use 2 sprockets and 2 chains

or 4 of them..

should be easy...

if you need help tell me..

no the chain wont be the weakest part.

it will be the clutch...

wy do they spec it 35NM then??

i made a error the chain sees 147Newtons on the front sprocket...

but because of the lower revs of the rear it sees 4 times this...

TKs

just use the original bike sprocket chain size and rear pinion.. over here they can make every thing you want.. cant see the problem..

and 2 + 2 = 4 pistons..  VFR is a 4 piston twin.. VFR is a 4 piston twin..

will try the cluctch but i gues it wont last for long..35 NM is 35NM...not??

Tks

The above comments are always meant to be from the above persons perspective.

|

|

|

tks

|

| posted on 30/11/06 at 05:48 PM |

|

|

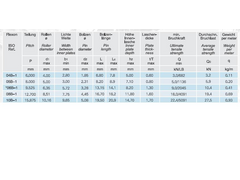

Regarding chain power

look at flexon.de for more details..

mine is the one with 9,65mm with..

The 5/8 inch.. 15,875mm...

Tks

min strenght 22.4 KN thats 22400Newton..

thats almost 2240Kg just the 2 tons i guessed..

Tks

[Edited on 30/11/06 by tks]

Rescued attachment ChainPower.JPG

The above comments are always meant to be from the above persons perspective.

|

|

|

tks

|

| posted on 30/11/06 at 09:34 PM |

|

|

the bullet is thrue the church!

i'm going to buy the 75mm version wich withstands 110NM

if see a poss to upgrade to a 90mm then iw ill do..

if i lieve the 35NM version i will need to change the elastic element every now and then and i don't like doing that. (a car is for driveing)

Tks

The above comments are always meant to be from the above persons perspective.

|

|

|

tks

|

| posted on 1/12/06 at 11:06 AM |

|

|

mhhh

I have ordered the 90mm version wich withstands 160NM

have spoken to the guys from the clutch company and the 110NM edition had a realy bad donut in it.. made from rubber..so it would absorp to much...and

would brake when overpowered...

the torque figures are all nominal, he said i could add 30% margen to it. also peaky torque pulses aren´t a problem..only long duration over torque is

a problem..sow with the 90 (160NM) i should be where i want to be!! Now just hoping i can move the clutch slave cilinder more to the engine..

(removing a spacer part wich is there...)

Tks

[Edited on 10/1/07 by tks]

The above comments are always meant to be from the above persons perspective.

|

|

|

tks

|

| posted on 10/1/07 at 06:23 PM |

|

|

PIC of install

where´s that damm clutch slave cilinder!!

Yupsz its on the same level as the output!!

Tks

Rescued attachment picture036.jpg

The above comments are always meant to be from the above persons perspective.

|

|

|