t.j.

|

| posted on 10/6/06 at 07:35 PM |

|

|

short Sump

I cut my sump in two

So now i should have 95 mm clearance under the sump and 40 mm engine under the frame.

Now i going to place and flat plate under the ali-sump 4 mm and shorten the pick-up for the oil.

I'm only wondering: When it is ready the sump is about 50mm shorter. at the front will the sump extended with the lost volume.

What will happen at 1g braking will the pick-up still have enough oil to catch?

[Edited on 10/6/06 by t.j.]

|

|

|

|

|

nitram38

|

| posted on 10/6/06 at 07:39 PM |

|

|

I have cut and shut sumps. I would increase the width of the sump to compensate for the lost capacity. Also a baffle plate welded in horizontally with

drain holes and a large hole for the oil pick up strainer will help to prevent oil surge or lack of oil.

|

|

|

JB

|

| posted on 11/6/06 at 06:21 AM |

|

|

Sumps

Oil Control in a shallow sump is not easy!

There are several problems. When the engine is not running you have the sump full. Running at high revs a lot of that oil is else where, in the oil

ways, a large amount in the rocker / cam box, around the crank (think of an egg whisk and how the egg clings to the sump) and what is in the sump is

quite frothy.

So you have to reduce the effects of the above, good drain back, crank scraper and then sump design.

Under braking the oil will move forward. If the pick up is at the front then no problem. If its at the back then you need to stop the oil going

forwards, a baffle will do, a trap door is better (one way flow).

So basically what you need is chamber around the pickup. Then each side of this you require an area where oil can be, so this will be extensions on

the sides of the sump. Trap doors allow one way flow.

A horizontal baffle is a good idea below the crank.

If you have a crank scraper then put wire mesh ontop of the baffle to absorb the oil flung off otherwise it will bounch straight back up.

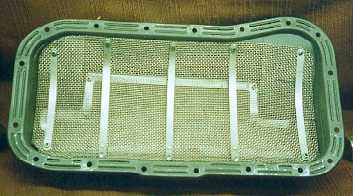

This is a sump for a transverse Lancia twin cam

Crank Scraper (an inline 16V Fiat)

Crank Scraper in position (16v Fiat)

Wire mesh in the sump (dry sump setup)

John

|

|

|

locostv8

|

| posted on 11/6/06 at 06:48 AM |

|

|

I like the "This is a sump for a transverse Lancia twin cam" pan I would assume it gets plated over. Also with a Locost with the bottom

of the pan area being open there is no reason why you couldn't extend the pan wings from front to rear.

http://wrangler.rutgers.edu/gallery2/v/7slotgrille/hssss/

|

|

|

t.j.

|

| posted on 11/6/06 at 10:37 AM |

|

|

This is how i want to do:

I've cut it like Paul did.

Then make a flat bottom towards the front.

Drill 3x6mm holes for extra air.

Make big hole at the bottom as big as the pick-up does have.

So the "extra"sump is slighty "slow" excessble.

Description

[Edited on 11/6/06 by t.j.]

|

|

|

NS Dev

|

| posted on 11/6/06 at 11:51 AM |

|

|

remeber you can (using the right type of foam!) foam fill sumps to prevent surge

Caterham did this with the HPC, and it is common in racing cars where rules prevent use of dry sump setups.

there are horror stories around but these are usually use of the wrong foam or incorrect installation etc.

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

t.j.

|

| posted on 14/6/06 at 05:00 PM |

|

|

someone must have an opinion on this.

Don't be shy  see picture see picture

[Edited on 14/6/06 by t.j.]

|

|

|

locostv8

|

| posted on 14/6/06 at 06:48 PM |

|

|

I assume you are leaving the pickup in it's original location. Split some 3" tubing and create wings and create a channel all around the

original sump. cut a slot like you show on all 4 sides and fashon trap doors out of piano hinge that swings inward. This should leave your pickup

covered at all times. This is best exampl;es I could find quick. Reweld pan with it fitted to an engine block.

http://www.cantonracingproducts.com/pans/circle_track/sbc_power_pans.html

[Edited on 14/6/06 by locostv8]

[Edited on 14/6/06 by locostv8]

http://wrangler.rutgers.edu/gallery2/v/7slotgrille/hssss/

|

|

|

PaulBuz

|

| posted on 14/6/06 at 07:07 PM |

|

|

T.J

sorry for not replying to your U2U quicker.

I thought I answer you here as I have to post pics.

I modded my sump as follows:

Rescued attachment Picture 524.jpg

ATB

Paul

|

|

|

PaulBuz

|

| posted on 14/6/06 at 07:08 PM |

|

|

More

Rescued attachment Picture 525.jpg

ATB

Paul

|

|

|

PaulBuz

|

| posted on 14/6/06 at 07:10 PM |

|

|

Plating

Rescued attachment Picture 532.jpg

ATB

Paul

|

|

|

PaulBuz

|

| posted on 14/6/06 at 07:24 PM |

|

|

Baffles

Rescued attachment small.jpg

ATB

Paul

|

|

|

PaulBuz

|

| posted on 14/6/06 at 07:24 PM |

|

|

more

Rescued attachment small1.jpg

ATB

Paul

|

|

|

PaulBuz

|

| posted on 14/6/06 at 07:26 PM |

|

|

All migged with a cheap Clark welder.

It aint no pretty tig job, but it does the job!!

No leaks. Holds white spirits overnight.

Rescued attachment smaller2.jpg

ATB

Paul

|

|

|

t.j.

|

| posted on 14/6/06 at 08:32 PM |

|

|

Thanx Paul,

This is what i'm looking for.

Greeting Theo

|

|

|