RazMan

|

| posted on 20/5/06 at 10:48 PM |

|

|

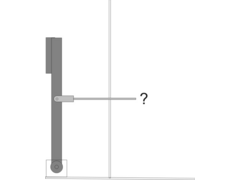

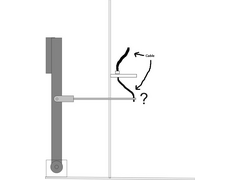

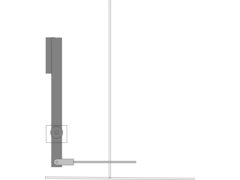

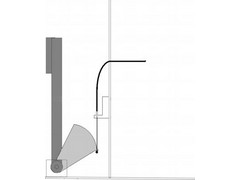

Accelerator linkage 'challenge'

I have my pedals floor mounted and the accellerator pedal pivots at the bottom. As a result I need to pass a clevis pin & pushrod through the

bulkhead, turn 90 degrees and convert the 'push' action to a 'pull' and connect it to my throttle cable which goes back up the

tunnel to the engine bay (middy).

Can anyone suggest a quick and easy way of doing this? I was thinking about a bell crank or quadrant which bolts on the bulkhead but I am hoping there

might be something a little more 'off the shelf' available somewhere.

Any ideas guys?

[Edited on 20-5-06 by RazMan]

Rescued attachment accellerator.jpg

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

|

|

Bob C

|

| posted on 20/5/06 at 11:02 PM |

|

|

rod? pushes cable sheath - cable inner nailed to bulkhead . . .???

Bob

|

|

|

RazMan

|

| posted on 20/5/06 at 11:15 PM |

|

|

Lateral thinking - I like it

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

Dusty

|

| posted on 20/5/06 at 11:22 PM |

|

|

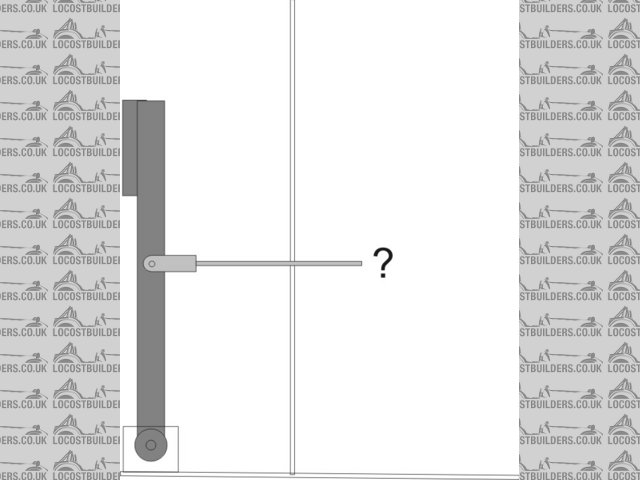

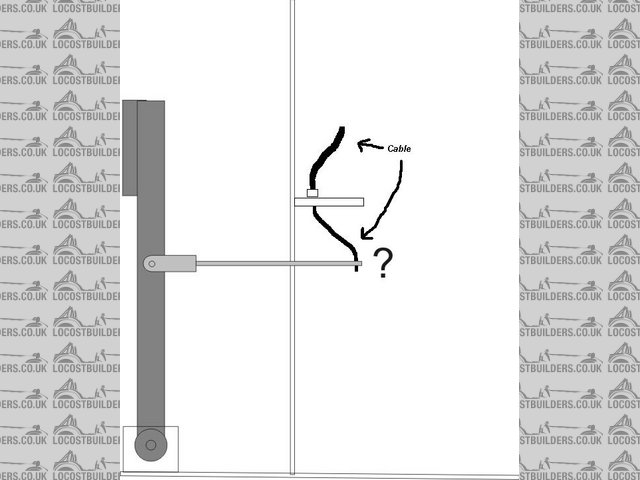

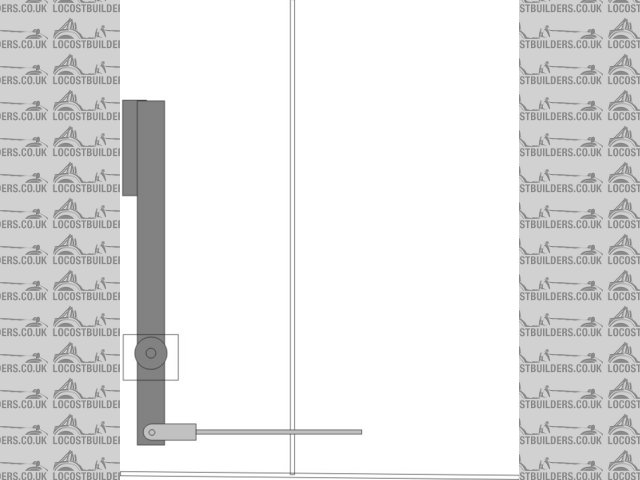

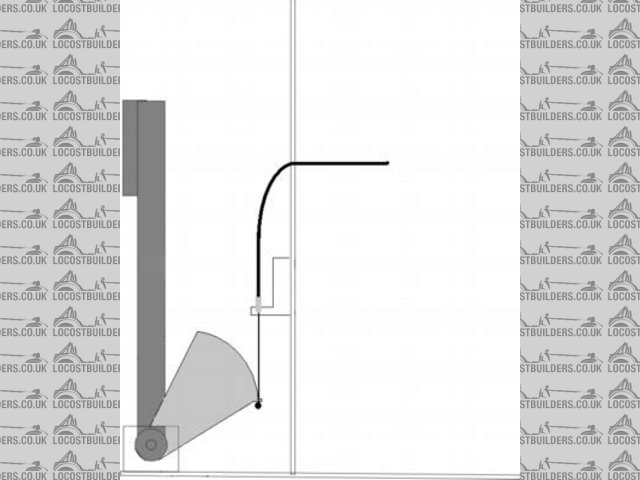

Possible to route a cable back into footwell and approach the pedal from the foot side with some sort of guard panel?

Rescued attachment accel.JPG

|

|

|

jonno

|

| posted on 20/5/06 at 11:40 PM |

|

|

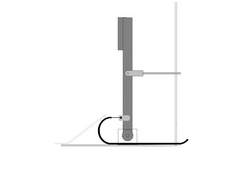

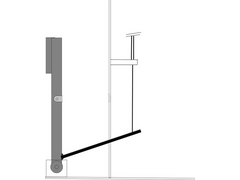

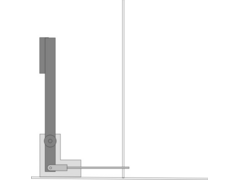

Or ??

Rescued attachment acc.jpg

|

|

|

907

|

| posted on 21/5/06 at 06:16 AM |

|

|

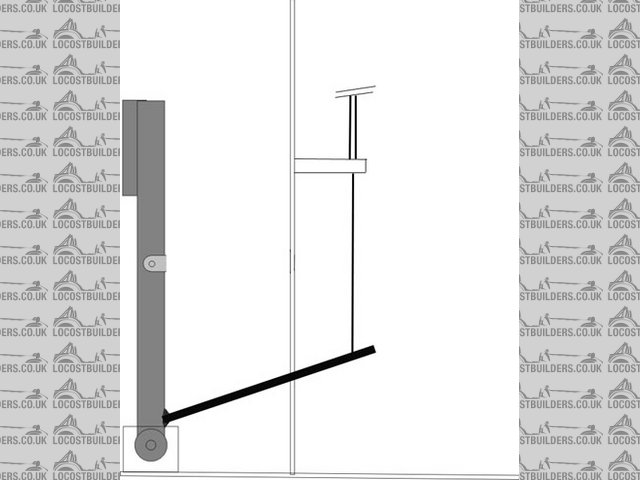

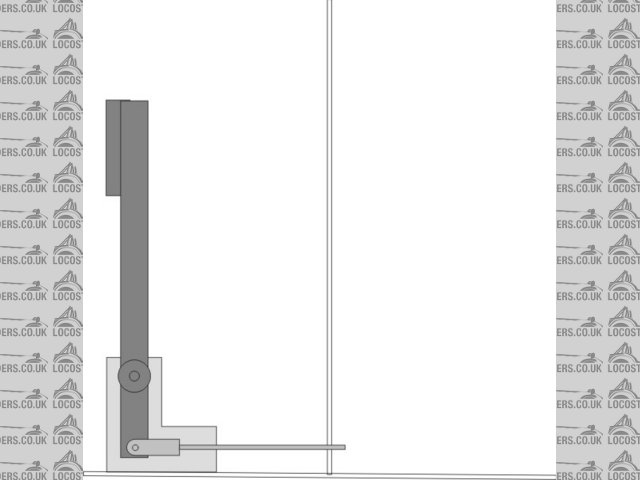

You would need to cut a slot in the bulkhead.

Paul G

Rescued attachment T-Linkage-s.jpg

|

|

|

big_wasa

|

| posted on 21/5/06 at 07:28 AM |

|

|

You will get a more reliable operation if you do it properly imho

You wont get the feeling by going through a bellcrank ect and its one more thing to go wrong.

|

|

|

RazMan

|

| posted on 21/5/06 at 10:31 AM |

|

|

Some really creative ideas there - thanks for all the input.

As suggested, I think the most sensible way would be to re-engineer the pedal and move the pivot point up and the clevis pin can then be attached

directly to the cable. The only problem there is achieving the correct amount of cable travel - I would have to move the pivot up quite a way to

achieve that. Is there any way of 'amplifying' pedal movement?

Rescued attachment Aeon Accelerator Pedal 2.jpg

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

RazMan

|

| posted on 21/5/06 at 12:11 PM |

|

|

I see what you mean but my V6 Duratec needs about 2" of cable travel to get WOT. If you are using bike TB's then that might explain the

difference.

Mark, what is the length of your pedal from the pivot?

I'll make a cardboard mock-up before I get the welder out

[Edited on 21-5-06 by RazMan]

Rescued attachment accellerator3.jpg

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

RazMan

|

| posted on 21/5/06 at 02:21 PM |

|

|

That's great Mark - all I have to do is convert the drawing into metal now

Thanks for all your help

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

andylancaster3000

|

| posted on 21/5/06 at 02:47 PM |

|

|

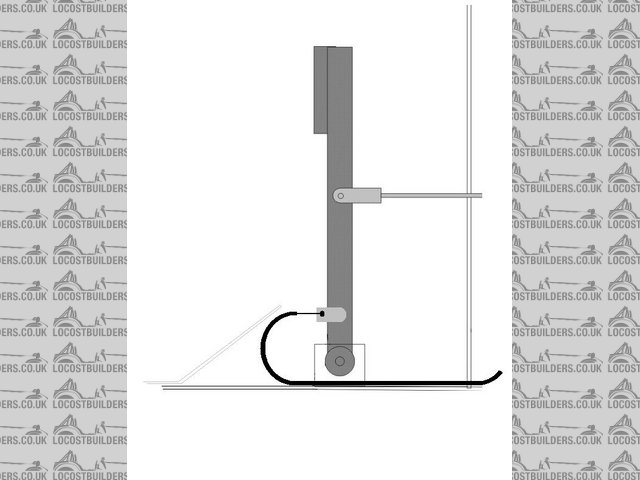

We did this as we found we couldn't easily get the required travel for the 40's attaching the cable below the pivot:

Seems to work very well. The bell crank has a pair of small bearings in it, it needs some rose joints as the plastic things are a bit flexy and work

at as nasty angle.

HTH,

Andy

[Edited on 21/5/06 by andylancaster3000]

|

|

|

RazMan

|

| posted on 21/5/06 at 08:04 PM |

|

|

Aha - something along the lines of my first thoughts.

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

Dusty

|

| posted on 24/5/06 at 03:28 AM |

|

|

Possibly think of a cut down grooved quadrant like the sierra clutch one. Nice linear pull, no extra friction and no levers. Adjust radius for

ratio.

[Edited on 24/5/06 by Dusty]

Rescued attachment accel.jpg

|

|

|