givemethebighammer

|

| posted on 8/12/02 at 07:35 PM |

|

|

DIY remote gaerchange

Anyone seen any details on how to build your own remote gear change device for a ford (or any other for that matter) type 9 gearbox ? Can't be that

hard to make

thanks

|

|

|

|

|

givemethebighammer

|

| posted on 8/12/02 at 07:42 PM |

|

|

gaerchange, oops slipped into dutch again, I wasn't suggesting that any other manufacturer make a type 9 gearbox (although they might). Its Sunday,

brain offline.

doh !!

|

|

|

Mr G

|

| posted on 8/12/02 at 08:21 PM |

|

|

Try here :

http://freespace.virgin.net/d.w.jenkins/gear_extend.htm

Cheers

G

|

|

|

givemethebighammer

|

| posted on 8/12/02 at 08:38 PM |

|

|

Looks good, if a little complicated at first.

Once I have read it whilst looking at the gearbox it should all make sense.

thanks

|

|

|

stephen_gusterson

|

| posted on 8/12/02 at 09:05 PM |

|

|

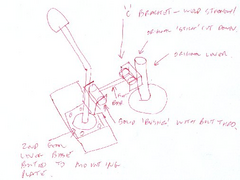

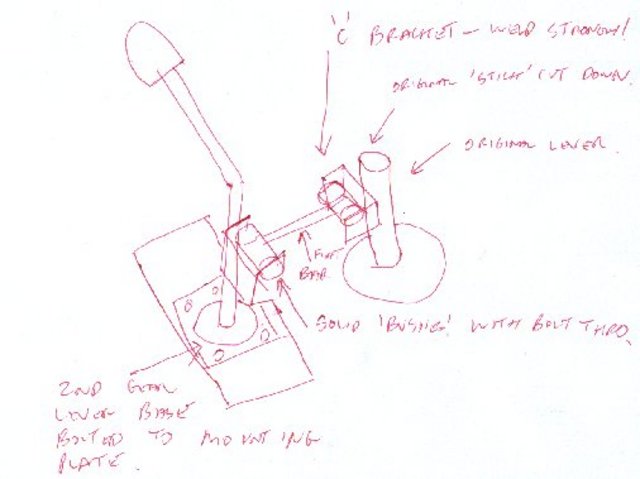

there is another way that I have seen on the net that looks a lot simpler.

I doubt I will remember where tho - so I will do a crap sketch and put it up shortly.

atb

steve

|

|

|

stephen_gusterson

|

| posted on 8/12/02 at 09:33 PM |

|

|

for what its worth

If you look at my standard of sketching, you will understand why I gave up tech drg at 14 and became a hardware / software engineer.

The following idea is not mine, I dont know how good or bad it is. I was going to make this mod on my car, and have the gear lever to do it with.

However, when I saw that its only 4 - 5 ins difference, I thought I would see what the std layout is like before I go to this hassle.

Basically, cut off the old gear lever at a point below the rubber 'bush' that acts as a vibration dampener. I remeber reading that you can free the

bush if needed by heat - ie torch it.

Inside the box somewhere where the lever comes off is a metal 'tang' - or it could be on the lever itself - that acts to prevent reverse selection

unless the lever is pulled (or pushed?) in the right direction to overcome the 'stop'. You have to take this off.

I cant remember how to re-instate it at the remote lever - but I am sure you can work out a way or be careful!

To the original lever shaft, weld a bracket - a bit like the one on the suspension. Weld it with as much bracing as you can

as this will take some 'leverage'. (really!)

Drill through a suitable rod (or use tube) which you weld a length of flat bar - say 30mm x 5mm to the drilled metal 'bush'. This bolts to the bracket

in such a way that it is allowed to pivot to allow forward and backward movement - ie - lets you select 1st or second.

you dont want this sloppy in the left right direction or your gearchange will feel crap.

Now, modify a second gear lever to have a similar braket at its base - be careful the welding heat does not melt the aforementioned vibration damper

thingy in the lever shaft.

Bolt the flat bar linkage via a second metal tube/bush to the bracket at the other end.

You now have a gearchange extension. I think if mounted low, you could hide all this in the tunnel or an extended cover over it.

I remember a note about using flat bar instead of rod as the linkage as it is less prone to twisting as you move from 2nd to 3rd across the gate.

I hope this is of some use - it does not seem to need a lathe - just a few bits of steel, a drill and a couple bolts and a welder.

atb

steve

[Edited on 8/12/02 by stephen_gusterson]

Rescued attachment Image2.jpg

|

|

|

locodude

|

| posted on 8/12/02 at 10:18 PM |

|

|

Same as mine, works a treat. Made a gate for the gearchange lever so don't need a reverse detent, just knock the stop out of the remote housing, and

hey presto!

|

|

|

David Jenkins

|

| posted on 9/12/02 at 08:58 AM |

|

|

quote:

Originally posted by givemethebighammer

Looks good, if a little complicated at first.

Once I have read it whilst looking at the gearbox it should all make sense.

thanks

Yes, it is more complicated that Steve's linkage - but it all fits within the tunnel, has the reverse detent where it's supposed to be, and the

reverse light switch works!

It operates by extending the gearbox main selector shaft. You need a lathe for the extension pice, and for its bearing, but apart from that it's

sheet metalwork.

regards,

David

|

|

|

locodude

|

| posted on 9/12/02 at 07:02 PM |

|

|

Reverse light , what reverse light, just adds more weight, don't need it, don't fit it! says he who's car is 30kg heavier now than when SVA'd

|

|

|

chrisg

|

| posted on 9/12/02 at 09:39 PM |

|

|

Got a Fog light though Chris................eh?

Cheers

Chris

Note to all: I really don't know when to leave well alone. I tried to get clever with the mods, then when they gave me a lifeline to see the

error of my ways, I tried to incite more trouble via u2u. So now I'm banned, never to return again. They should have done it years ago!

|

|

|

locodude

|

| posted on 10/12/02 at 06:26 PM |

|

|

I presume our resident sarcasamist means fogleet!

|

|

|

chrisg

|

| posted on 10/12/02 at 07:23 PM |

|

|

yes, out with the lip balm!!!

Cheers

Chris

Note to all: I really don't know when to leave well alone. I tried to get clever with the mods, then when they gave me a lifeline to see the

error of my ways, I tried to incite more trouble via u2u. So now I'm banned, never to return again. They should have done it years ago!

|

|

|

givemethebighammer

|

| posted on 10/12/02 at 08:44 PM |

|

|

Meanwhile back at the workshop...

After reading this

http://freespace.virgin.net/d.w.jenkins/gear_extend.htm

and looking very closely at my gearbox. It is not as complicated at you would first think.. I'm off find a lathe

thanks guys

|

|

|

phil

|

| posted on 10/12/02 at 09:04 PM |

|

|

While taking out some bedford rascal seats, i took a shine to the h/brake lever and removed the console , sitting underneath was the gearlever mounted

remotely via cables. If i hadn't used a similar method to Steve's then i would have tried to use the rascal one, sorry don't know what the g/box

cable ends are like , but must be worth a look if your desperate. good luck Phil.........

|

|

|

stephen_gusterson

|

| posted on 11/12/02 at 10:02 PM |

|

|

quote:

Originally posted by phil

While taking out some bedford rascal seats, i took a shine to the h/brake lever and removed the console , sitting underneath was the gearlever mounted

remotely via cables. If i hadn't used a similar method to Steve's then i would have tried to use the rascal one, sorry don't know what the g/box

cable ends are like , but must be worth a look if your desperate. good luck Phil.........

Suppose it must work on the Rascal, but I would have thought it was quite hard to make up a cable system that didnt have a fair bit of 'backlash' in

it?

atb

steve

|

|

|

Stu16v

|

| posted on 11/12/02 at 11:21 PM |

|

|

Quite a few commercial vans use 'cable change'. Another car to use it was the first Maxi's......

Dont larf, quite a few of you have Maxi bottom ball joints......

Dont just build it.....make it!

|

|

|

David Jenkins

|

| posted on 12/12/02 at 09:01 AM |

|

|

quote:

Originally posted by givemethebighammer

Meanwhile back at the workshop...

After reading this

http://freespace.virgin.net/d.w.jenkins/gear_extend.htm

and looking very closely at my gearbox. It is not as complicated at you would first think.. I'm off find a lathe

thanks guys

...and don't forget, it can be as long as you like! (Ooer, missus!)

David

|

|

|

David Jenkins

|

| posted on 12/12/02 at 09:03 AM |

|

|

quote:

Originally posted by locodude

Reverse light , what reverse light, just adds more weight, don't need it, don't fit it! says he who's car is 30kg heavier now than when SVA'd

I'm going for ultra-convenient, not ultra-light, so I don't really care about an extra 2 ounces of plastic and wire...

DJ

|

|

|

bob

|

| posted on 12/12/02 at 09:29 AM |

|

|

quote:

Originally posted by Stu16v

Quite a few commercial vans use 'cable change'. Another car to use it was the first Maxi's......

Dont larf, quite a few of you have Maxi bottom ball joints......

And dont forget the BEC boys use the cable linkage

|

|

|

jmbillings

|

| posted on 12/12/02 at 11:53 PM |

|

|

We used Steves "bar" method (but with square section tube). MK also suggested this way. Works a treat. One thing we did is to not grin off the

reverse stop altogether but just file it a bit- if you have ever driven a BMW, you will know what its like- there is resistance to push it across to

Reverse, but you dont actually have to push it down.

|

|

|

stephen_gusterson

|

| posted on 13/12/02 at 08:06 PM |

|

|

yep - i do know what the 318 is like - when I took delivery of it it almost needed two hands to put it in reverse! freed up after a while.

atb

steve

|

|

|

Peteff

|

| posted on 14/12/02 at 12:39 AM |

|

|

gaerchange extension

I used a type 9 gearbox and a 2ltr pinto and the gear lever is in the ideal position without any modification. What you need is longer arms or mount

your engine further back. or mount

your engine further back.

yours, Pete.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|