Nickp

|

| posted on 10/2/16 at 07:12 AM |

|

|

Prop catcher?

Guys, I've just bolted up my new D&F prop and am considering where to put a front prop catcher. The easiest and most obvious place is

directly behind the front UJ on the narrow section. But what if the prop was to fail on the sliding joint or where it joins the main fatter section of

prop? How likely is this? Am I been over cautious?

Thanks in advance

|

|

|

|

|

adithorp

|

| posted on 10/2/16 at 07:37 AM |

|

|

I'd put it behind the weld on the tube. Not as easy but I've seen pictures of props that have failed at the weld.

Could you hang it off those brackets above?

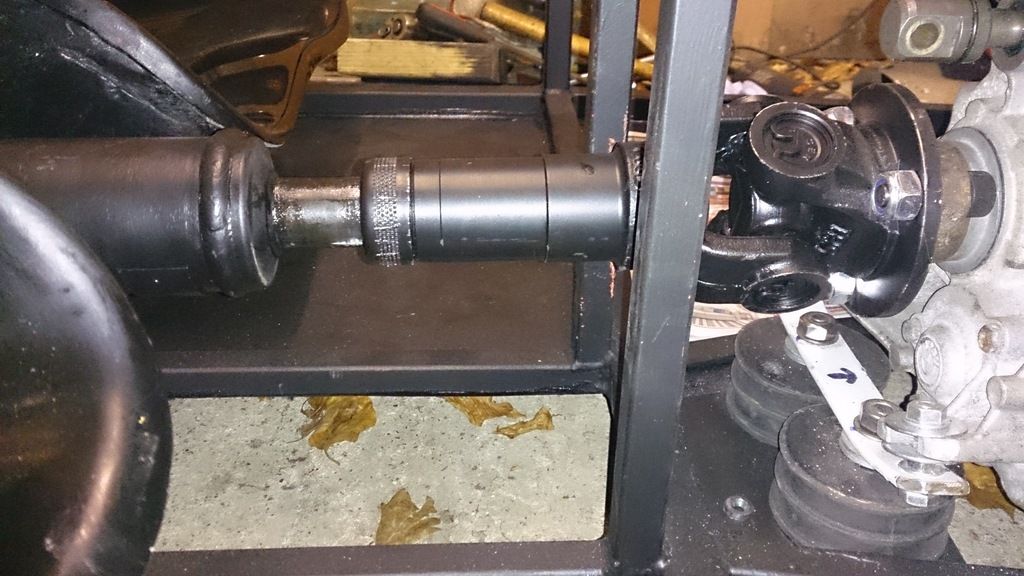

This is my front one...

[Edited on 10/2/16 by adithorp]

"A witty saying proves nothing" Voltaire

http://jpsc.org.uk/forum/

|

|

|

Nickp

|

| posted on 10/2/16 at 07:47 AM |

|

|

quote:

Originally posted by adithorp

I'd put it behind the weld on the tube. Not as easy but I've seen pictures of props that have failed at the weld.

Could you hang it off those brackets above?

This is my front one...

[Edited on 10/2/16 by adithorp]

The weld on the main tube? That would seem to be the safest option. I was wondering about using an appropriately sized exhaust u-clamp, bolted

securely into place. Should be strong enough as long as it's tight enough around the prop to prevent it getting a good 'whip on'?

Yes' those brackets above could be an option. They're for the gear change but I'll look at hanging the prop catcher off them, maybe

an upside down version of what you have there adi

[Edited on 10/2/16 by Nickp]

|

|

|

hizzi

|

| posted on 10/2/16 at 08:49 AM |

|

|

instead of a prop catcher i welded a couple extra uprights on the tunnel

|

|

|

Nickp

|

| posted on 10/2/16 at 10:18 AM |

|

|

quote:

Originally posted by hizzi

instead of a prop catcher i welded a couple extra uprights on the tunnel

That may well offer me and my occupant some protection but wouldn't stop a flailing prop taking out my fuel / brake lines, smashing my tunnel

and possibly digging into the ground

|

|

|

joneh

|

| posted on 10/2/16 at 12:41 PM |

|

|

I'd go over the weld both ends. Here's mine below - big one for the diff end, little one for the gearbox end. Made from 3mm steel plate.

The bigger one has 3mm plate welded around the inside of the hole to make it stronger.

Description

|

|

|

adithorp

|

| posted on 10/2/16 at 02:26 PM |

|

|

quote:

Originally posted by joneh

I'd go over the weld both ends.

Not sure I'd want to do that. HAZ from the weld might be worse and it'd need re-balencing.

The D shape of my prop'catcher is probablynot ideal but it was a simpler to make that way. At the time I was against the clock to get it all

rebuilt before a trip, so it was all a bit last minute. In the picture the prop is resting in the corner with the max amount of mis-alignment it can

get.

"A witty saying proves nothing" Voltaire

http://jpsc.org.uk/forum/

|

|

|

Nickp

|

| posted on 10/2/16 at 05:40 PM |

|

|

quote:

Originally posted by adithorp

quote:

Originally posted by joneh

I'd go over the weld both ends.

Not sure I'd want to do that.

No, me neither. In fact I'm sure I won't be doing that!!

|

|

|

Nickp

|

| posted on 10/2/16 at 05:41 PM |

|

|

quote:

Originally posted by joneh

Description

Ta, they look plenty beefy enough!

|

|

|

joneh

|

| posted on 10/2/16 at 05:44 PM |

|

|

quote:

Originally posted by Nickp

quote:

Originally posted by adithorp

quote:

Originally posted by joneh

I'd go over the weld both ends.

Not sure I'd want to do that.

No, me neither. In fact I'm sure I won't be doing that!!

Ha! What I meant to say is go past the weld, as in have the catcher further in so that its caught if the weld lets go (where the prop goes from thin

to fat)

[Edited on 10/2/16 by joneh]

|

|

|

Nickp

|

| posted on 10/2/16 at 05:54 PM |

|

|

quote:

Originally posted by joneh

quote:

Originally posted by Nickp

quote:

Originally posted by adithorp

quote:

Originally posted by joneh

I'd go over the weld both ends.

Not sure I'd want to do that.

No, me neither. In fact I'm sure I won't be doing that!!

Ha! What I meant to say is go past the weld, as in have the catcher further in so that its caught if the weld lets go (where the prop goes from thin

to fat)

[Edited on 10/2/16 by joneh]

Phew!!

|

|

|

adithorp

|

| posted on 10/2/16 at 09:26 PM |

|

|

quote:

Originally posted by joneh

Ha! What I meant to say is go past the weld, as in have the catcher further in so that its caught if the weld lets go (where the prop goes from thin

to fat)

[Edited on 10/2/16 by joneh]

Ah, I see.

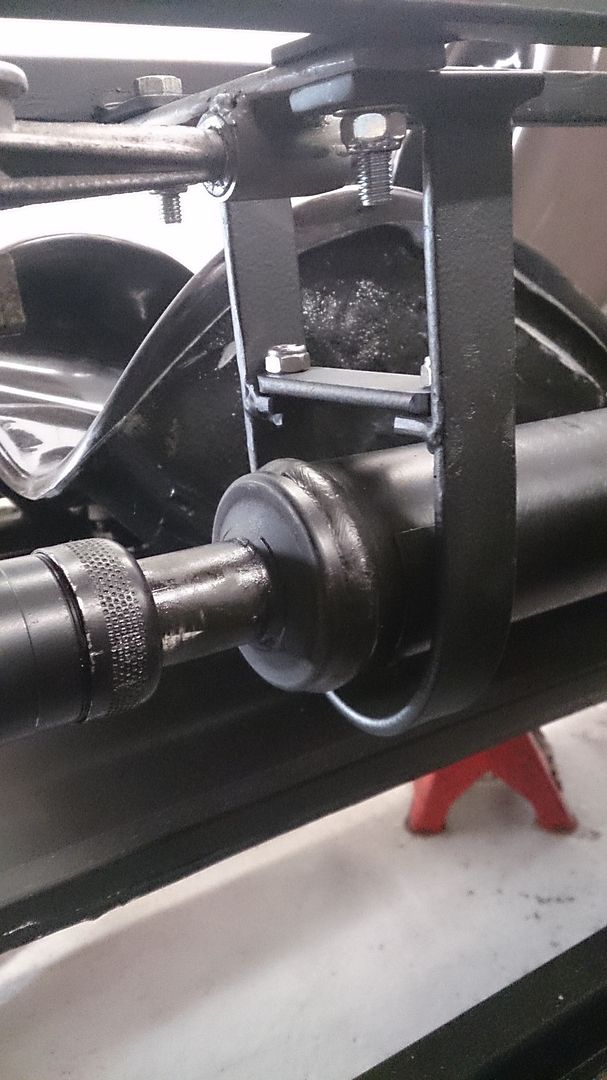

This is the one I have at the diff end. Again kept it simple and they don't have to be as strong as some people think as long as they keep the

prop' fairly close to it's original alignment...

"A witty saying proves nothing" Voltaire

http://jpsc.org.uk/forum/

|

|

|

Nickp

|

| posted on 15/2/16 at 10:09 AM |

|

|

Prop catcher done, ta for the inspiration adi

|

|

|

emwmarine

|

| posted on 15/2/16 at 01:01 PM |

|

|

Probably a stupid question but how did you bend the steel into the correct semi circle?

Building a Dax Rush.

|

|

|

Nickp

|

| posted on 15/2/16 at 03:15 PM |

|

|

I bent it round an old prop. Laid the bar on the ground and put the prop across it and stood on it. Not an exact science but worked near enough for

this

|

|

|

emwmarine

|

| posted on 15/2/16 at 03:53 PM |

|

|

and there I was expecting something scientific like a Machinemart ACME flat steel bender.

What thickness steel? 3mm?

Building a Dax Rush.

|

|

|

Nickp

|

| posted on 15/2/16 at 04:59 PM |

|

|

quote:

Originally posted by emwmarine

and there I was expecting something scientific like a Machinemart ACME flat steel bender.

What thickness steel? 3mm?

Scientific? Up here in Yorkshire?

It's 5x25mm bar, took a bit of bending tbh!!

|

|

|