Valtra

|

posted on 9/6/13 at 06:13 PM posted on 9/6/13 at 06:13 PM |

|

|

overheating and scalded face !!!!

Had my first drive and couldn't get it running smoothly using speed density so tried Alpha N and instantly the car started running properly and

not chucking out black smoke. But this time squealing like a kettle from the header tank. Waited a few minutes until it had settled before removing

the pressure cap.....not long enough it seems as boiling water/antifreeze gushed out all over the engine and into my face.....now watching the Grand

Prix wearing a bit of sunburn sensation but at least I can see..

Now have to work out why I'm overheating any suggestions gratefully received. wondering if I either had some sort of airlock or the thermostat

has seized shut , but I only drove a very short distance on a cool day would that cause overheating?

"If it looks like it works and it feels like it works, then it works"

|

|

|

|

|

Slimy38

|

| posted on 9/6/13 at 06:30 PM |

|

|

The last time I opened the header tank on a hot car, it did pretty much what you describe although my face wasn't in the way. There was nothing

wrong with that car, apart from an owner who didn't listen to the warnings about opening the coolant cap on a hot car. At least the engine got

steam cleaned...

Or is that not the reason why you think the car overheated? What did the temperature gauge say?

|

|

|

dave_424

|

| posted on 9/6/13 at 07:05 PM |

|

|

Also, sometimes there is a delay between raking the cap off and it spewing out coolant that's hotter than a Mcdonalds apple pie

Just a warning so people don't put their eye over the hole after nothing seems to happen as they take the cap off.

|

|

|

britishtrident

|

| posted on 9/6/13 at 08:21 PM |

|

|

It sounds like the coolant isn't circulating, I don't know how you have the car plumbed but you need a by-pass hose ie a hose that

takes coolant back from the hot side of the thermostat back to the water pump inlet. This allows coolant to circulate when the thermostat is closed

and this continuous coolant flow stops hot spots forming in the engine and allows the thermostat to open.

In modern tintops the by-pass is formed by continuous water flow through the heater but if you have old fashioned heater with a water valve you

controlling the heat must fit an additional by-pass hose.

In addition you should drill one or no more that two holes in the thermostat valve plate the holes should be 2mm to 25.mm dia this helps air

bleed and allows the thermostat to respond more quickly.

I would also check you have enough ignition advance through thee whole rpm range.

[I] “ What use our work, Bennet, if we cannot care for those we love? .”

― From BBC TV/Amazon's Ripper Street.

[/I]

|

|

|

Valtra

|

| posted on 9/6/13 at 08:35 PM |

|

|

quote:

Originally posted by Slimy38

The last time I opened the header tank on a hot car, it did pretty much what you describe although my face wasn't in the way. There was nothing

wrong with that car, apart from an owner who didn't listen to the warnings about opening the coolant cap on a hot car. At least the engine got

steam cleaned...

Or is that not the reason why you think the car overheated? What did the temperature gauge say?

Not sure what the guage(s) were saying about temps as I was concentrating on the header cap squealing , I wonder now if I had the header tank too

full so that as the water heated up the header tank got too full hence the plastic (with rubber valve) causing such a row. I took that cap off first

with no issues . Removed the actual pressure cap slowly but turned it too far.... ouch. So could be simply too much water ?

"If it looks like it works and it feels like it works, then it works"

|

|

|

Valtra

|

| posted on 9/6/13 at 08:53 PM |

|

|

quote:

Originally posted by britishtrident

It sounds like the coolant isn't circulating, I don't know how you have the car plumbed but you need a by-pass hose ie a hose that

takes coolant back from the hot side of the thermostat back to the water pump inlet. This allows coolant to circulate when the thermostat is closed

and this continuous coolant flow stops hot spots forming in the engine and allows the thermostat to open.

In modern tintops the by-pass is formed by continuous water flow through the heater but if you have old fashioned heater with a water valve you

controlling the heat must fit an additional by-pass hose.

In addition you should drill one or no more that two holes in the thermostat valve plate the holes should be 2mm to 25.mm dia this helps air

bleed and allows the thermostat to respond more quickly.

I would also check you have enough ignition advance through thee whole rpm range.

Car is plumbed just as it was before the engine rebuild and for that mater just as the Fiat 131 was plumbed when I ripped out the engine 18 years ago.

that is not to say for definite that the thermostat is not knackered. however the radiator was hot top and bottom.

Would an engine at correct operating temperature spurt like Vesuvius a few minutes after stopping?

"If it looks like it works and it feels like it works, then it works"

|

|

|

Valtra

|

| posted on 9/6/13 at 09:22 PM |

|

|

Lean running causes overheating but I'd probably driven less than 5 miles in total and certainly less than 2 miles on Alfa N (i.e not way too

rich) Thinking about it now the heater valve was stuck open when I drained the system prior to re-build but closed when I refilled the system so could

have caused an air lock ?

"If it looks like it works and it feels like it works, then it works"

|

|

|

Valtra

|

| posted on 13/6/13 at 10:40 PM |

|

|

Carefully filled up the water system I have a vent at the highest point to purge all the air . tried running again and again it got very hot very

quickly . I had issues with the engine leaning right out to stall So have to assume this is causing extreme overheating over and above the likely

similar tendancy to run leaner than twin 40's whilst using fuel injection. will see if I can encourage it to run a little on the rich side to

see if it helps cooling

"If it looks like it works and it feels like it works, then it works"

|

|

|

britishtrident

|

| posted on 14/6/13 at 07:10 AM |

|

|

Is the ignition getting enough advance ? nothing causes overheating faster than retarded ignition.

[I] “ What use our work, Bennet, if we cannot care for those we love? .”

― From BBC TV/Amazon's Ripper Street.

[/I]

|

|

|

Not Anumber

|

| posted on 14/6/13 at 10:35 AM |

|

|

Try running it without the thermostat in and the pressure cap off for a while from cold to get rid of air leaks. Top up the coolant and take it for a

drive. If all is well it would then be worth checking the thermostats operating by dropping it into a heatproof glass jar full of boiling water.

|

|

|

Valtra

|

| posted on 14/6/13 at 12:26 PM |

|

|

quote:

Originally posted by Not Anumber

Try running it without the thermostat in and the pressure cap off for a while from cold to get rid of air leaks. Top up the coolant and take it for a

drive. If all is well it would then be worth checking the thermostats operating by dropping it into a heatproof glass jar full of boiling water.

Thanks

I'm pretty sure the Thermostat is opening as the rad is getting hot ( the switch for the fan is in the rad and the fan is working) and in any

case it is not easily removable as it sits in a sealed canister separate from the engine . As for ignition advance I'll try to post up the

standard tuner studio map that it's been using, it may be that there could be a cause there if I haven't got my advance curves right (or

even got them disabled somehow )

"If it looks like it works and it feels like it works, then it works"

|

|

|

dave_424

|

| posted on 14/6/13 at 12:53 PM |

|

|

You aren't still running on the fixed 10deg timing are you?

You should be able to see on your ignition advance gauge in tunerstudio weather or not it is staying at 10 deg or is following your ignition curve.

Dave

|

|

|

Valtra

|

| posted on 14/6/13 at 09:14 PM |

|

|

quote:

Originally posted by dave_424

You aren't still running on the fixed 10deg timing are you?

You should be able to see on your ignition advance gauge in tunerstudio weather or not it is staying at 10 deg or is following your ignition curve.

Dave

Pretty sure I'm not but will check as I had a major ecu failure due to stupidity early on so it may have reverted back to static advance

"If it looks like it works and it feels like it works, then it works"

|

|

|

Valtra

|

| posted on 15/6/13 at 08:20 PM |

|

|

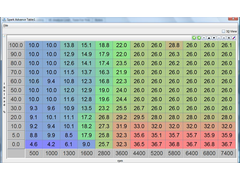

Description

this is the inbuilt spark advance table in microsquirt . can anybody see a problem ?

"If it looks like it works and it feels like it works, then it works"

|

|

|

dave_424

|

| posted on 15/6/13 at 08:24 PM |

|

|

I'm no expert, but I thought that full ignition should be around 32-36 degrees. Was the trigger wheel tooth offset set up correctly with a

timing light?

|

|

|

Valtra

|

| posted on 15/6/13 at 09:01 PM |

|

|

quote:

Originally posted by dave_424

I'm no expert, but I thought that full ignition should be around 32-36 degrees. Was the trigger wheel tooth offset set up correctly with a

timing light?

When you say "full " ignition, where is that on the table bearing in mind my car is running in and won't be revving much over 6000

even when it is .

I've not checked the "static " timing since whipping the head back off following the water leak , which means I had to remove the vr

sensor to change the cam belt , but it can't be far out (was absolutely spot on initially

"If it looks like it works and it feels like it works, then it works"

|

|

|

dave_424

|

| posted on 15/6/13 at 09:07 PM |

|

|

As in your maximum ignition advance in the table. I don't know how your bracket is made and how well it would return to its position, if you

have a tonight light then it would be worth a check.

Other than spark and fuel being lean I don't really know what the problem is. Seems as though you have ruled out the possibility of it being in

the coolant system

|

|

|

Valtra

|

| posted on 15/6/13 at 09:53 PM |

|

|

Thanks I'll re check the static timing just to make sure but the bracket is pretty stiff and secure so I doubt it is far wrong . Have wondered

if the thermostat could be stuck partially open and thus not circulating properly , may be worth investing in a new one to rule out the possibility

"If it looks like it works and it feels like it works, then it works"

|

|

|

Dusty

|

| posted on 15/6/13 at 11:42 PM |

|

|

quote:

....header...... I took that cap off first with no issues . Removed the actual pressure cap slowly but turned it too far.... ouch. So could be simply

too much water ?

Odd! With the header tank cap removed surely the whole cooling system should be depressurised.

Subsequently getting sprayed when removing the pressure cap (from where and why two caps?) suggests a plumbing fault. Not sure I understand your

system! Heat soak plus air in the system could possibly explain a delayed eruption but it doesn't quite sound right.

[Edited on 15/6/13 by Dusty]

|

|

|

Valtra

|

| posted on 16/6/13 at 12:25 AM |

|

|

quote:

Originally posted by Dusty

quote:

....header...... I took that cap off first with no issues . Removed the actual pressure cap slowly but turned it too far.... ouch. So could be simply

too much water ?

Odd! With the header tank cap removed surely the whole cooling system should be depressurised.

Subsequently getting sprayed when removing the pressure cap (from where and why two caps?) suggests a plumbing fault. Not sure I understand your

system! Heat soak plus air in the system could possibly explain a delayed eruption but it doesn't quite sound right.

[Edited on 15/6/13 by Dusty]

Hi

I plumbed the cooling system using all the components of the Fiat the engine came from With the exception that the Rad sits lower than the engine so I

put a tight plain cap on the rad and made a filling point with the original pressure cap at the front of the engine where the top hose enters . this

also has an overflow hose going up to the header tank as high as I could get it on the scuttle. the system is designed so that as the water in the

engine expands it forces past the pressure cap into the expansion(header) tank, which is hot but not under pressure as the air escapes through a

rubber valve in the plastic header tank cap . As the engine cools it sucks water back from the header tank .

If this is plumbed wrong then it worked fine before with carbs so I'm a little perplexed

Description

[Edited on 16/6/13 by Valtra]

"If it looks like it works and it feels like it works, then it works"

|

|

|

britishtrident

|

| posted on 16/6/13 at 06:51 AM |

|

|

Looks way to retarded to me, with an old fashioned purely centrifugal advance max advance was reached around 3,500 RPM -- note this is driven by

crank rpm not load.

On most engine there is no gain in adding more ignition advance over this crankshaft speed.

Try setting the full load ignition advance to 15 degrees at 1200 rpm and 36 degrees at 3,500 rpm with a straight line in between.

Because they of the poor combustion chamber shape which gives slow combustion because of the long flame path and lack of turbulence two valve twin

cam engines with hemi combustion chambers need a lot of advance so you may find using more advance at the high end is required. 40 degrees advance

at full throttle is pretty well the limit.

[Edited on 16/6/13 by britishtrident]

[I] “ What use our work, Bennet, if we cannot care for those we love? .”

― From BBC TV/Amazon's Ripper Street.

[/I]

|

|

|

Valtra

|

| posted on 16/6/13 at 09:32 AM |

|

|

Thanks I'll look into that . I'm also wondering if the Innovate LC1 is calibrated quite right in tuner studio as I have a G5 gauge that

reads a bit different to the Tuner studio gauge from memory so it could be fooling the ecu into leaning back too much . I'll do a free air

calibration and see if there is a correlation .

"If it looks like it works and it feels like it works, then it works"

|

|

|

Valtra

|

| posted on 16/6/13 at 09:45 AM |

|

|

quote:

Originally posted by britishtrident

Looks way to retarded to me, with an old fashioned purely centrifugal advance max advance was reached around 3,500 RPM -- note this is driven by

crank rpm not load.

On most engine there is no gain in adding more ignition advance over this crankshaft speed.

Try setting the full load ignition advance to 15 degrees at 1200 rpm and 36 degrees at 3,500 rpm with a straight line in between.

Because they of the poor combustion chamber shape which gives slow combustion because of the long flame path and lack of turbulence two valve twin

cam engines with hemi combustion chambers need a lot of advance so you may find using more advance at the high end is required. 40 degrees advance

at full throttle is pretty well the limit.

[Edited on 16/6/13 by britishtrident]

Also excuse my ignorance but when you say full load you mean the top line of the table should read with those figures ? what about lower down at

lower load ? Have you some suggested figures for the bottom line and how they should progress up the load and rev range ?

"If it looks like it works and it feels like it works, then it works"

|

|

|

dave_424

|

| posted on 16/6/13 at 09:54 AM |

|

|

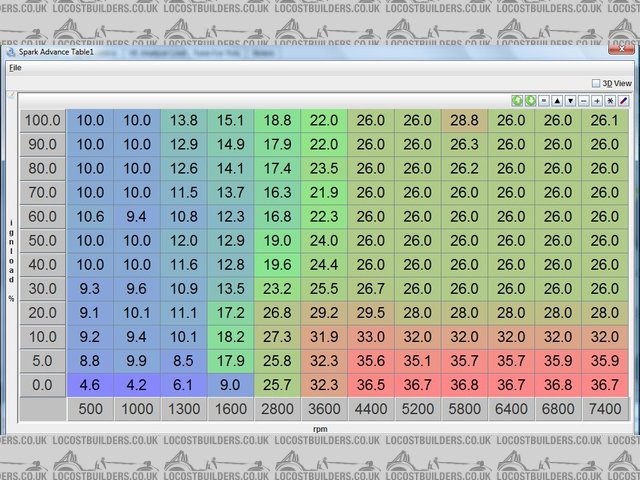

This is a megasquirt map that I downloaded to get something to work off, lower RPM area might have a degree or two too much advance for your engine.

Also note that it is for a bike engine so the RPM's would have to be bought down to match your engine's rev range.

|

|

|

Valtra

|

| posted on 16/6/13 at 12:23 PM |

|

|

Thanks Dave

I'll nudge my advance up a little towards these figures and see if I can make a difference , if I self tune in tuner studio will it change the

advance anyway? or does it concentrate on fuel load only

"If it looks like it works and it feels like it works, then it works"

|

|

|