tompat3463

|

| posted on 12/3/13 at 07:02 PM |

|

|

Bike drive idea ?!? thoughts please

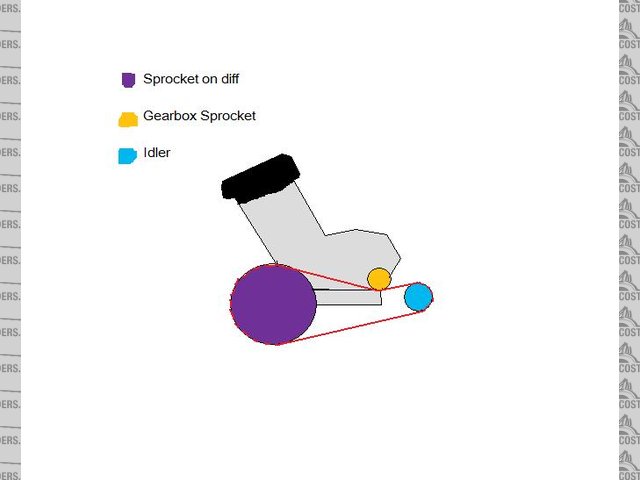

I will firstly apologise for the quality of my drawing

can any of you see this set up to have any problems.

heres the scenario.

bike engines in the front of a mini make for an extremely short chain thus shortening chain life and possible damage to engine...

Description

so why not turn the engine 180 degrees and use the gearbox sprocket on the engine as a kind of chain tentioner inbetween the diff sprocket and an

idler sprocket towards the front of the car.

this would give a longer chain .

the one problem im thinking is that the gearbox sprocket would only be biting on to the chain with maybe 4-5 teeth but I think this could be over come

by lowing the engine onto the chain more thus wrapping it around the chain more.

The smaller idler on the front end of the system would be adjustable so you could tension the chain as required.

please let me know your thoughts and please be honest I wont be offended.

thanks Alan

[Edited on 12/3/13 by tompat3463]

|

|

|

|

|

imp paul

|

| posted on 12/3/13 at 07:11 PM |

|

|

looking at the set up i feel it would not work safely, and would jump teeth looks like a bad idea mate  but Alan i do believe pro motive did a

front diff/ set up you could google it mate but Alan i do believe pro motive did a

front diff/ set up you could google it mate

here you go http://www.pro-motive.co.uk/

[Edited on 12/3/13 by imp paul]

|

|

|

adithorp

|

| posted on 12/3/13 at 07:20 PM |

|

|

You'll need a lot more wrap around the sprocket to prevent it slipping/jumping teeth or a LOT of tension in the chain and that'd make it

wear the chain.

"A witty saying proves nothing" Voltaire

http://jpsc.org.uk/forum/

|

|

|

MikeRJ

|

| posted on 12/3/13 at 07:22 PM |

|

|

Won't work, you need to wrap the sprocket far more, especially with a small sprocket. Also you'd have to extend the sprocket out

significantly from the bike gearbox, as the engine castings would prevent you running the chain forward like that. That would place a lot of stress

on the gearbox output shaft bearing, so you'd probably want to support the sprocket with another external bearing.

One possibility is to make the run with two chains, each sharing part of the overall reduction. This would mean the "small" sprockets

doesn't have to be very small anymore which significantly improves chain life.

[Edited on 12/3/13 by MikeRJ]

|

|

|

tompat3463

|

| posted on 12/3/13 at 07:27 PM |

|

|

thans for the replies..

the promotive kit is exactly why I though of this as I want it to be as DIY as possible.

I did think the chain would need to be wrapped round more.

MikeRJ i dont think it would make the system run the wrong way as the gearbox sprocket is effectively pulling the chain of the top of the diff

sprocket therefore driving the wheels forward. remember the engine is facing the wrong way.

Ill have a remeasure and re draw  and see how much 'wrap around' I can get and see how much 'wrap around' I can get

cheers people

|

|

|

MikeRJ

|

| posted on 12/3/13 at 07:44 PM |

|

|

quote:

Originally posted by tompat3463

thans for the replies..

the promotive kit is exactly why I though of this as I want it to be as DIY as possible.

I did think the chain would need to be wrapped round more.

MikeRJ i dont think it would make the system run the wrong way as the gearbox sprocket is effectively pulling the chain of the top of the diff

sprocket therefore driving the wheels forward. remember the engine is facing the wrong way.

Yup, I realised that when I re-read your first post and found you where reversing the direction of the engine as well! Tried to post a pic of a two

chain solution, but LCB is behaving very oddly with pictures for me (the first uploaded image links to a completely different picture, if I upload it

again with the different name the picture is correct but avatar sized!).

|

|

|

Slimy38

|

| posted on 12/3/13 at 08:37 PM |

|

|

If you're wanting to overcome the disadvantage of having such a short chain, can't you do away with the chain altogether and use gear

wheels, similar to a FWD car gearbox and diff combo? You'd have to fix the diff to the engine but it might have fewer mechanical and maintenance

issues.

|

|

|

tompat3463

|

| posted on 12/3/13 at 09:09 PM |

|

|

I was thinking of using gears but I didn't like the fact that they would be open to the elements if u didn't fabricate some sort of

enclosure for them. Looking at the engine again it seems my original plan doesn't work either as mentioned above the engine casings foul the

chain !

Looks like its going to be a shot chain

|

|

|

cloudy

|

| posted on 12/3/13 at 09:15 PM |

|

|

I think a short chain is less of an issue than you think - yes they reduce the life of the chain, but the slight increase in running cost is somewhat

offset by only having to buy shorter lengths of chain...

The R4 runs sprockets with perhaps 10cm between them, and have only ever needed to replace the chain once (wasn't using a heavy duty chain and

the issue was uneven stretch from hard launches rather than wear)

I personally wouldn't worry about it! Just use a good high quality chain with the highest ratings you can find....

James

[Edited on 12/3/13 by cloudy]

www.warnercars.com

|

|

|