David Jenkins

|

| posted on 10/9/04 at 10:49 AM |

|

|

Loss of oil pressure on a crossflow

As I've said on the SVA area, I failed to get to my test because I started to lose oil pressure on the way... now I need to find out why!

Symptoms:

Engine running fine throughout the whole affair, will no loss of poke.

Already done around 25 miles without any sign of problems before starting the journey to the SVA centre. As my journey is down the A12 I just had to

travel 40 miles at around 65-70mph or I'd get mowed down by something - it's a very busy road.

I'd done around 35 miles when I had to lift off the throttle due to traffic, and my oil light came on. At the same time the oil gauge reading

dropped. When I accelerated again (I had to) the oil light went out and the gauge picked up, but only to around 20psi instead of the 40-50psi I had

before.

Managed to get into Chelmsford OK, stopped to check the oil level and top up the fuel tank prior to the test. Oil level was fine (as was everything

else) and there were no signs of leaks. I let everything cool down and tried to start the engine but couldn't raise any pressure at all, so

gave up and called the rescue man.

This is a totally rebuilt engine that has been running well. My first thought is that the oil pump has failed, possibly the oil relief valve has

stuck, or similar. However, I may be grasping at straws...

Could anyone who's experienced in these engines suggest any other cause, given the symptoms? That is: running properly; oil pressure loss on

lifting the throttle (pretty much to tick-over); then no pressure at all when trying to restart after cooling the engine down.

Fortunately the engine only ran for a few seconds with zero pressure, and still seems OK.

Help!

David

|

|

|

|

|

timf

|

| posted on 10/9/04 at 11:02 AM |

|

|

only seen this once on a x-flow the roll pin securing the screw gear on the shaft shearing giving no drive to the pump.

was it a new pump or a rebuild

if rebuild what are the rotor clearences like

|

|

|

nick205

|

| posted on 10/9/04 at 12:03 PM |

|

|

Just a thought, but is it worth checking that the sender and gauge are both OK?

Nick

|

|

|

DaveFJ

|

| posted on 10/9/04 at 12:35 PM |

|

|

maybe i'm being a little to obvious here but...

could it not be oil starvation due to oil moving around in the sump ?

the oil pump could possibly then have problems recovering from a 'gulp of air' ?

we used to experience this problem with hydraulic pumps on aircraft when the seals or drives started to get a bit dodgy

[Edited on 10/9/04 by protofj]

Dave

"In Support of Help the Heroes" - Always

|

|

|

stephen_gusterson

|

| posted on 10/9/04 at 12:37 PM |

|

|

seems a bit unlikely that both devices would fail.....

And why a sudden drop to lower, or zilch at tickover, pressure....

Looking at Timf's broken pin idea, I wonder if there was enougth 'drag' by the broken parts to drive the pump for a while, with the

drag being too low at tickover.......

atb

steve

[Edited on 10/9/04 by stephen_gusterson]

|

|

|

David Jenkins

|

| posted on 10/9/04 at 02:13 PM |

|

|

Well, I've just swapped the oil pump for the original old one - believed to be OK - no sign of oil pressure when I spin the engine over with the

plugs out.

I'm beginning to suspect that the oil pickup pipe may be faulty - clutching at straws again...

David

|

|

|

stephen_gusterson

|

| posted on 10/9/04 at 02:22 PM |

|

|

whatever it is David, you are SOOOO close to having a car on the road you should still have a smile on your face whilst looking for the fault.

its better than a whole loada messy grp work!

atb

steve

|

|

|

Hellfire

|

| posted on 10/9/04 at 04:23 PM |

|

|

IIRC Steve of MK had a very similar problem. ISTR he had this problem just before his shells went... but I may be wrong!

|

|

|

David Jenkins

|

| posted on 11/9/04 at 09:54 AM |

|

|

When I became a little less peeved I gave this some thought and decided that the engine needs to be hauled out - not such a big task, just a

nuisance.

Previously I tried to remove the sump with the engine in the car - front wheels on ramps, engine hauled forward a few inches, and so on. It worked,

but I hurt myself in the process: pulled muscles wriggling under the car, bruises, and so on. If it isn't the oil pickup pipe then the engine

has to come out anyway, to inspect the bearings.

It'll also give me an opportunity to deal with some annoyances that I've been putting off (such as an oil filter that can't be

unscrewed without lifting the engine). Also I will split the metal plate that goes between the engine in the gearbox - one of the reasons working on

the sump under the car was such a pain.

This will be a job for tomorrow though - I've got to be nice to my missus today, because I was such a grumpy rat-bag yesterday!

cheers,

David

(who's feeling a little less pee'd off today)

|

|

|

David Jenkins

|

| posted on 11/9/04 at 03:58 PM |

|

|

Dave,

Lots of things to consider!

The sump was shortened, but there was an extension that made the oil volume the same. I used the same dipstick and it worked out OK.

The engine hasn't settled at all.

The previous problem I had was down to a user-ability error - I'd screwed the oil pressure switch and gauge sender into the wrong hole! Worked

fine when I put it right.

I've tried 2 pumps now and, unless both have stuck valves, it's not likely to be that.

The fact that car ran very well for 50-60 miles of assorted driving suggests that the oil levels & system weren't far wrong.

The engine is now almost ready to come out - at this moment the oil is draining, and then I'll drain the water. It's been relatively

simple to disconnect the engine from the rest of the car (X-flows are like Meccano anyway!) and I should have no difficulty separating it from the

gearbox, once I remove the alternator to give me some room to move the block forward.

cheers,

David

|

|

|

Rob Lane

|

| posted on 11/9/04 at 05:45 PM |

|

|

Hmm wonder what happened? I posted a reply earlier today but it hasn't appeared.

Anyway.

Bearing pressure loss would usually be accompanied by the death rattle. Is the remaining oil greyish or swirly metallic looking?

Pressure loss at revs change suggests that either pressure relief stayed open or a loss of pump drive. The fact that it then picked up but at lower

pressure suggests a sticky spring.

Easier to check on Xflow because it's external pump, although relief valve is in face of pump.

It could be pickup problem of course, hard to tell when ones been modified.

If one bearing has gone then a loss of pressure would occur but it usually can be run up to 10psi or so, not usually zero, without major damage having

occured with attendant noises.

|

|

|

David Jenkins

|

| posted on 11/9/04 at 06:58 PM |

|

|

Rob,

I didn't hear any obvious noises, apart from the tappets tapping a bit louder than usual due to the lack of oil - but it's a bit hard to

hear when you've got a full-face helmet on! Once I knew I had a problem I didn't push my luck, and left the engine switched off.

The oil I've just drained off looked "clean but used" if you know what I mean - no sign of metal particles.

I know what's what tomorrow when I lift the engine out and take the sump off - I still suspect the oil pickup pipe as the oil pump had no oil in

it when I took it off - normally there's an appreciable spill when you detach the pump. The chambers looked quite dry.

One problem I have is that I have no idea where the oil pressure relief valve is! I know it's on the mounting face but there's not much

to see when you take the pump off. Anyone have a good picture to give me a clue?

Even if the pickup is obviously a problem when I look tomorrow I'll probably still take the bearing caps off to make sure that there's no

significant scoring or wear. While the engine's out I might as well make the most of the opportunity...

Incidentally, on reflection I wouldn't be too surprised if it's a bearing failure - from the outset I was concerned about doing a 40-mile

thrash with a brand-new engine, as that's no way to run in a newly-assembled engine. I was only doing 3500rpm max to get 70mph, but that

requires a fair amount of power so the engine had to work hard. If that is the case, then I hope that just the shells are spoilt, and not the crank

surfaces.

Anyone in the Ipswich area know someone with a trailer I can borrow (for a few notes, if necessary). I'll probably hire a van and tow my car on

a trailer next time - I can run the engine in properly in varied local driving after the test.

rgds,

David

[Edited on 11/9/04 by David Jenkins]

|

|

|

jacko

|

| posted on 11/9/04 at 07:36 PM |

|

|

OIL

Hi Dave just a thought could the pickup pipe be to close to the bottom of the sump starving the engine of oil jacko

|

|

|

David Jenkins

|

| posted on 11/9/04 at 08:47 PM |

|

|

Thanks, Dave!

How can I tell if it's stuck? Can I prod it with a screwdriver or something?

rgds,

David

|

|

|

David Jenkins

|

| posted on 12/9/04 at 04:07 PM |

|

|

Now I'm puzzled...

Well, the engine's out and on a stand.

- The oil pickup pipe was in place, and intact.

- The pressure relief valve was clean and functional.

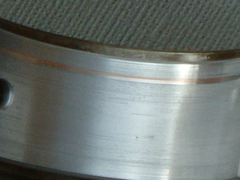

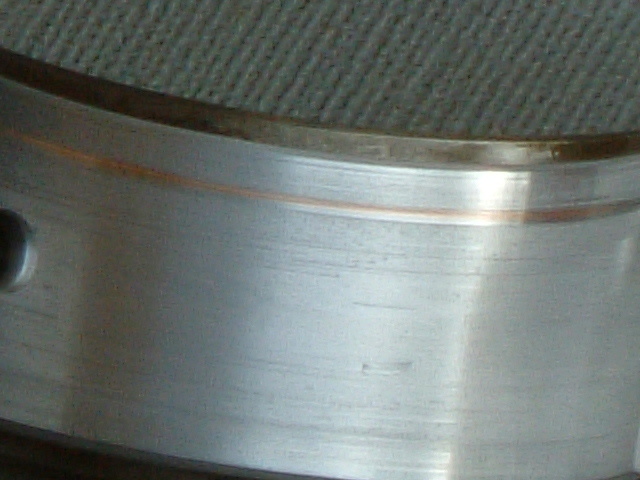

- I've checked all the bottom-end bearings: the mains are a nice smooth matt grey, and all but one of the crank bottom bearings were grey with a

slight shine. One of the bearings had a copper-coloured stripe, as shown below, but I can't imagine that this would cause a total oil pressure

failure (would it?). All crank journals were clean and unmarked.

Apart from replacing the damaged bearing, I can't think what to do next - anyone got any suggestions?

David

Rescued attachment dscf0003.jpg

|

|

|

rusty nuts

|

| posted on 12/9/04 at 05:31 PM |

|

|

David, was the oil pick up pipe gasket/seal in place and undamaged with the securing bolts tight?? loose bolts or damaged seal could cause loss of or

low oil pressure.and would explain why oil pressure dropped off. Also, I.I.R.C. crossflows should run on 20/50. thinner oil would probably not be

suitable, hope this helps, Rusty.

|

|

|

David Jenkins

|

| posted on 12/9/04 at 06:18 PM |

|

|

Rusty,

The x-flow oil pickup pipe is just a tube that jams into a hole, with a bolt elsewhere that stops the assembly fall off. There was some sealant

around the pipe where it went into the block.

I was using 20-50W - Castrol GTX, in fact.

Anyone know whether the cam bearings often cause trouble? I don't want to get in there unless I have to - it's a fair bit of work to get

at it, and it means partially stripping the head to take the pressure off the push-rods.

David

|

|

|

DEAN C.

|

| posted on 12/9/04 at 06:38 PM |

|

|

As previously suggested have you checked the pin and gears that drive the pump,if not is there any pin holes in the pikup pipe. Cam bearins dont

really drop pressure its definately a bottom end problem,and that shell wont cause a drop either,unless the crank us bad..

DEAN.....

Once I've finished a project why do I start another?

|

|

|

theconrodkid

|

| posted on 12/9/04 at 06:50 PM |

|

|

is the pump working?fill it with oil and turn the input gear,oil should come out the hole at quite a rate

who cares who wins

pass the pork pies

|

|

|

timf

|

| posted on 13/9/04 at 08:54 AM |

|

|

david

how far from the bottom of the sump is the pickup. could it be that due to vibration the pick up has dropped towards the sump.

maybe time for the playdo check

tim

|

|

|

David Jenkins

|

| posted on 13/9/04 at 09:52 AM |

|

|

The oil pickup was still solidly mounted, so I guess that it was OK.

Just a thought - I was wondering whether my 20-50 oil had overheated due to the A12 thrash, and had become too thin for the old-fashioned engine.

Alternatively, are there any internal oilway plugs on a x-flow that may have come undone? Ones that would let the oil back into the sump, rather than

to the outside world.

rgds,

David

|

|

|

stephen_gusterson

|

| posted on 13/9/04 at 09:55 AM |

|

|

surely once the engine is cool again, the oil pressure would rise if due to overheated oil......

atb

steve

|

|

|

skinny

|

| posted on 13/9/04 at 10:50 AM |

|

|

quote:

Originally posted by David Jenkins

Just a thought - I was wondering whether my 20-50 oil had overheated due to the A12 thrash, and had become too thin for the old-fashioned

engine.

i think it's unlikely the oil got too thin for the engine, 20W-50 is one of the thicker oils you can get at high temperature so should retain

fairly viscous compared to a thinner grade of oil. Having said that, 20W-50 is a mineral oil and not of especially good quality - it requires quite a

lot of polymer to get the high temperature viscosity - if the oil has been used quite a lot, this polymer can actually get chopped up and be far less

effective. The difference in viscosity between a 50 grade and 40 grade is actually quite small at high temperatures, I would maybe advise going for a

semi-synthetic 10W-40.

If it did overheat, it's unlikely the viscosity of the oil contributed much to the temperature increase through shearing / resistance, so an oil

that is even thicker at high temperatures would be recommended. Without wishing to advertise  , there is a fully synthetic 10W-60 oil available for

high performance / fast road use. , there is a fully synthetic 10W-60 oil available for

high performance / fast road use.

[Edited on 13/9/04 by skinny]

if you don't fail, you aren't trying hard enough.

|

|

|

Rob Lane

|

| posted on 13/9/04 at 10:57 AM |

|

|

The copper line is a dirt pickup score mark, this would not cause complete loss of oil pressure on it's own.

Complete loss points to oil pump related problem if shells OK.

The lube progress is as follows:-

Pickup to pump via filter. Pump to galleries feeding mains then through crank drillings to big ends.

Also mains to cam bearings with excess then onto rocker shaft whereby it leaves rockers and drains down drip feeding pushrods and cam lobes on way

back to sump.

From above you're left with pickup, filter, pump as main cause other than bearing failure of course.

Any air leak in pickup will cause loss of pressure.

Check the filter, can't remember but it may have a drain spring plate. Prevents oil draining back to sump via filter.

Are you sure gauge is working OK ?

The pressure take off is on the gallery immediately after pump.

I'm puzzled that loss of pressure was not accompanied by bearing noise or such.

Before you stripped it did you start it up on tickover? I don't trust electrical gauges to show anything when cranking. Capillary gauges,

yes.

Any gallery plugs missing would result in oil everywhere. One is on block side, one is in block end under timing cover, another in flywheel end of

block. They look like ball bearings jammed in.

Good rebuilders of engines remove these and clear out oilways with chemical cleaning follwed by pipe cleaner type brushes.

Rob

|

|

|

stretch

|

| posted on 13/9/04 at 01:02 PM |

|

|

OK, stop worring! this might be your problem

i had the same problem, after modifing the sump and tuning the motor,

reason why your oil pressure droped is prob a breathing problem, with to much sump presure the oil doesnt return to the bottom of the motor - it

happend to me!

have a look at the little breather tank on the side of the motor, if its not blocked, there is valve in there that you can take out aswell - to just

let it breathe

then once the oilpump and the pickup is empty - wany a water needs to run into the sea before it will suck oil up again. U need to fill the pump and

the pickup pipe with oil then it will pump again

let me know what happens! i'll find a pic of my breather system.

regards

riaan

|

|

|