Bob C

|

| posted on 30/7/04 at 11:49 AM |

|

|

DIY V8 from 2 bike engines

I saw a website recently called "cyclone" or something like, where they'd stuck 2 R1 cylinder blocks onto a single crank to make a

320bhp 2litre V8. Awesome nutter loony etc & I'm gonna try & make one with a fabricated aluminium crackcase - job for 2 or 3 years

hence. I was thinking of using 2x 600cc engines to get a 1.2litre 210hp. Thing is though - this thing will rev to 14000 - can a bog standard gearbox

take that many revs.

Interesting project - one cylinder head has to run bacwards - anybody know if the cam lobes are symmetrical? or will I have to reverse the cam drive

somehow.

All pie in the sky dreaming - but just imagine the noise it would make.........

Cheers

Bob C

|

|

|

|

|

stephen_gusterson

|

| posted on 30/7/04 at 12:11 PM |

|

|

I think Ned posted a pic on here a year or so back of a V8 made from 2 bike engines.... perhaps you could u2u him about it...

he's been a bit rare lately - looks liek hols time!

atb

steve

|

|

|

dmottaway

|

| posted on 30/7/04 at 12:15 PM |

|

|

I know that making it a V8 results in a compact engine, but making it a straight 8 may be easier.

I had an uncle that took two Indian 4 cylinder engines and merged them into a single straight 6! No blueprints, just the mind of a master machinist.

Hung the engine on a stretched Harley Davidson frame. What a smooth ride.

If you can read Italian, you can read about it at

http://www.ideahobby.it/dbasp-motoaz/MotoAZ.asp?id=01548&tab=TabB&src=

dave

|

|

|

Bob C

|

| posted on 30/7/04 at 12:31 PM |

|

|

found it - googled cyclone + V8 &there it was - based in poole, dorset.

I note from their website that they reverse the cam drive to one of the heads. It's doable but means gears which is a bit sad...

Cost - 2 600cc engines - not a lot, custom steel crank.... ouch! mate with tig welder - 6 pints of lager.

Inline takes the torque of 1 engine through the other which I don't like the sound of - mind you the big end journals size is fixed so

I'll have to look closely at the crank anyway.

So nobody's pushed 14k revs through an mt75 or type9 gearbox then.....

Bob

|

|

|

colibriman

|

| posted on 30/7/04 at 01:02 PM |

|

|

how would the electronics part of it work.....??

curious....

saw the engine a while back at a show..

awesome stuff...

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

mangogrooveworkshop

|

| posted on 30/7/04 at 01:21 PM |

|

|

15 k for the cyclone! Some where out on the web is a catervan having one fitted! They also have one in a seven roundbutt (Quantum) but the gear box

clutch was a nightmare.

|

|

|

Bob C

|

| posted on 30/7/04 at 01:56 PM |

|

|

As I see it, if you run with a flat plane 1342 crank all you have to do is have 2 sets of bike CDI units & all the carbs - bingo.

Or (bigger project) a motec or emerald ecu

I suppose it's fair enough that no-one has tried 14krpm into an escort gearbox... how could they?

cheers

Bob

£15k!!!! - should be able to pick up an old dfv for less than that.....

|

|

|

phelpsa

|

| posted on 30/7/04 at 02:26 PM |

|

|

The cyclone is two hayabusa engines stuck together and creates about 350bhp. TTS do a super charger kit for the standard hayabusa engine (ie. not V8)

that takes it up to 500bhp....

Get the way I am talking, 1000bhp twin supercharger V8 hayabusa    . .

Good luck finding a gearbox

Adam

|

|

|

JoelP

|

| posted on 30/7/04 at 02:34 PM |

|

|

i've thought about this in the past, but i couldnt think how there was room for 8 piston arms (big end is it?) on the crank. How do they get

round this? i always wanted a busa twin turbo, but maybe thats just a little excessive.

|

|

|

stephen_gusterson

|

| posted on 30/7/04 at 03:11 PM |

|

|

the site says its a 2 litre engine- and isnt the busa 1.3 litres?

the maths dont work....

atb

steve

|

|

|

stephen_gusterson

|

| posted on 30/7/04 at 03:16 PM |

|

|

quote:

Originally posted by JoelP

i've thought about this in the past, but i couldnt think how there was room for 8 piston arms (big end is it?) on the crank. How do they get

round this? i always wanted a busa twin turbo, but maybe thats just a little excessive.

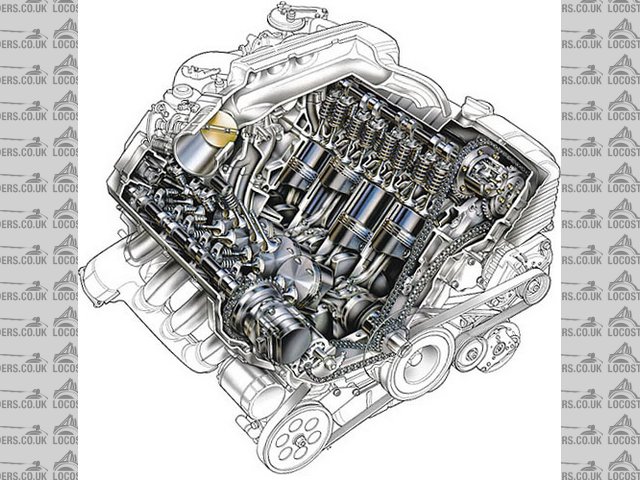

V engines (to my limited experience) have two con rods per crank pin. Therefore a v8 would have 4 big end crank pins, with two big end bearings /

cranks on each. The big end crank surfaces would need to be wider.

this v8 crank shows the wear mark between each con rod bearing area

atb

steve

[Edited on 30/7/04 by stephen_gusterson]

Rescued attachment crankshaft_camshaft.jpg

|

|

|

MikeR

|

| posted on 30/7/04 at 03:43 PM |

|

|

surely the easier option is to take two bike v4's and mate those together....

BMW's spring to mind as a good starting point, bullet proof in std form...... although i seem to recall not highly tunned.

|

|

|

phelpsa

|

| posted on 30/7/04 at 03:52 PM |

|

|

2 VFR800s.

Adam

|

|

|

undecided

|

| posted on 30/7/04 at 06:50 PM |

|

|

The engine is two Yamaha Thunder Ace top ends grafted onto a tricky set of crankcases..neat bit is the way the cams run as the blocks are back to

back.......2.0ltr v8 screamer....very cool.

|

|

|

undecided

|

| posted on 30/7/04 at 06:52 PM |

|

|

why vfr's.....Yamaha is the kiddie to have....ask that geezer with number 46 on the front!

|

|

|

derf

|

| posted on 30/7/04 at 07:05 PM |

|

|

Here are some photos from neds website:

|

|

|

JoelP

|

| posted on 30/7/04 at 07:39 PM |

|

|

quote:

Originally posted by stephen_gusterson

V engines (to my limited experience) have two con rods per crank pin. Therefore a v8 would have 4 big end crank pins, with two big end bearings /

cranks on each. The big end crank surfaces would need to be wider.

i see. But what exactly is a conrod? (dont say its a john...!). Ah, ive just got it, each of the pairs goes to a different bank of cylinders so they

dont collide...

|

|

|

stephen_gusterson

|

| posted on 30/7/04 at 07:47 PM |

|

|

yes, you got it

crank goes to conrod goes to piston

and each of the pair goes to a seperate 'bank' of cylinders.

Rescued attachment stockengine8cyl.jpg

|

|

|

Peteff

|

| posted on 30/7/04 at 07:56 PM |

|

|

Conrod = connecting rod

They run two conrods per big end journal on the crank and offset the cylinder banks to make room for them. The cost of doing this on a custom bottom

end and crank must be astronomical.

[Edited on 30/7/04 by Peteff]

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

Bob C

|

| posted on 30/7/04 at 08:19 PM |

|

|

Getting a crank dug out of a big chunk of steel shouldn't be too bad, it's common practise for tuned/rally/race engines. For the custom

crankcase I planned to fabricate from ally plates tig welded up - there's some history for this approach, in fact TVR used a fabricated crancase

in their recent V12.

Plus remember I'm just shooting the breeze for the next couple of years on this - IF it looks practical I'll start building in 2006!

cheers

Bob

PS I still can't see why a normal gearbox should'nt be run at 2x speed - nothing will break, the main worry is lubrication - will all the

oil get thrown off????

|

|

|

Bob C

|

| posted on 30/7/04 at 08:24 PM |

|

|

wow - I've been promoted - now "senior builder" and 4 stars. And its all happened when I went off on one about making my own engine

- - the rewards of utter bullsh1te, it doesn't only help at work!

Bob C (senior)

|

|

|

Cita

|

| posted on 30/7/04 at 08:46 PM |

|

|

Congratulations Bob!

|

|

|

JoelP

|

| posted on 30/7/04 at 09:17 PM |

|

|

bloody part timers...

guess how i got to this many!

|

|

|

paulf

|

| posted on 30/7/04 at 09:29 PM |

|

|

I once considered building a V twin to put in a morgan three wheeler replica and intended to either get the crankcase cast or fabricate it from plate

with bolts and dowels.and use 2CV barrels and heads.However never got around to it as I started building a seven instead, maybe it could be my next

big project.

Surely it would be easier to make a billet crankcase, it would be stronger lighter and more stable than a welded fabrication .A welded crankase would

also have to be very carefully stress relived and machined to avoid distortion, as the tolerances involved are a maximum run out on the main bearing

housings of half a thou.

Maybe a primary reduction gear could be used to drive a car gearbox as in bike engines.

Paul.

quote:

Originally posted by Bob C

For the custom crankcase I planned to fabricate from ally plates tig welded up - there's some history for this approach, in fact TVR used a

fabricated crancase in their recent V12.

Plus remember I'm just shooting the breeze for the next couple of years on this - IF it looks practical I'll start building in 2006!

cheers

Bob

PS I still can't see why a normal gearbox should'nt be run at 2x speed - nothing will break, the main worry is lubrication - will all the

oil get thrown off????

|

|

|

crbrlfrost

|

| posted on 30/7/04 at 09:34 PM |

|

|

Western Washington University in the US built a 554cc V8 based on two kawasaki 250cc heads and ran the timing chains off opposite ends of the crank.

Their block was cnc'ed from solid (16 hours I think) and was structural, worth a google search. One other example used the yamaha heads with the

central chain and just flipped the head. I would guess the cams are symetric, but a little poking around could confirm that. Seems the route to follow

for the crank is a flat plane, two rods per throw which allows you to tune the exhausts as two 4-cylinders, kind of nice. Flat cranks used in V8

theoretically can produce some vibration problems, but it doesn't seem to have been much of a problem with the small displacement (tiny bob

weight?) But I'm to lazy right now to do the sums. Frankly, I don't see a problem with a fabricated block as long as it was finish

machined. Look at Ferrari F1 gearboxes Tig'ed out of titanium, beautiful and accurate <drooling>. Hope you try it, sound like a awesome

project. Cheers!

|

|

|