boggle

|

| posted on 30/3/10 at 09:10 PM |

|

|

trigger wheel....part 2...

so i cut two two trigger wheels...

not sure what one to use...

both 6mm mild steel.....

thanks mr lardarse for the drawings...

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

|

|

blakep82

|

| posted on 30/3/10 at 09:11 PM |

|

|

er, what ignition system?

i'd go with the one on the right myself

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

Daddylonglegs

|

| posted on 30/3/10 at 09:12 PM |

|

|

Not much of an expert Barry, but I reckon the one on the right loks a little more substantial. Not sure what flexing can occur in the other one?

Either way, good job

JB

It looks like the Midget is winning at the moment......

|

|

|

boggle

|

| posted on 30/3/10 at 09:15 PM |

|

|

blake.....its a megajolt....

john...i like my traction engine one

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

cd.thomson

|

| posted on 30/3/10 at 09:16 PM |

|

|

those trigger wheels wont work with MJ

http://trigger-wheels.com/store/index1.html

[Edited on 30/3/10 by cd.thomson]

Craig

|

|

|

blakep82

|

| posted on 30/3/10 at 09:17 PM |

|

|

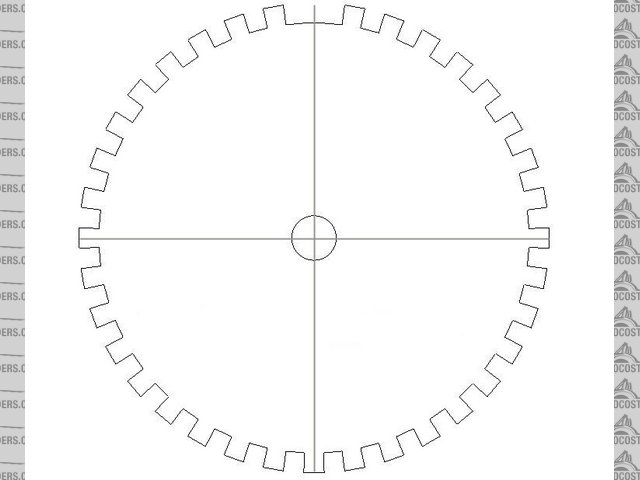

for mega jolt it should be 36 teeth (with 1 missing) if its with ford edis

think it needs a few more teeth

a bit like this

[Edited on 30/3/10 by blakep82]

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

Daddylonglegs

|

| posted on 30/3/10 at 09:22 PM |

|

|

quote:

Originally posted by boggle

john...i like my traction engine one

See where you're coming from

It looks like the Midget is winning at the moment......

|

|

|

boggle

|

| posted on 30/3/10 at 09:23 PM |

|

|

bollocks....

anyone got a drawing or sizes of what i do need???

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

cd.thomson

|

| posted on 30/3/10 at 09:24 PM |

|

|

pictures on the link I posted boggle

Craig

|

|

|

blakep82

|

| posted on 30/3/10 at 09:25 PM |

|

|

hmm, not really, but basically needs to be equally size teeth and gaps. 36 of them (so a tooth every 10 degrees) and 1 of the teeth is missing (so you

actaully end up with 35 on the wheel)

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

boggle

|

| posted on 30/3/10 at 09:28 PM |

|

|

need the tooth sizes, land, root diameter and overall diamter.....

can anyone help with these???

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

blakep82

|

| posted on 30/3/10 at 09:35 PM |

|

|

you won't be able to put this in the machine, but

Description

the size of the teeth will depend on the diameter of the wheel. that picture is the one i used to have mine made, and mine works. just copy that and

scale it up or down to what you need

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

boggle

|

| posted on 30/3/10 at 09:41 PM |

|

|

so diameter is unimportant?? just the amount of teeth?

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

blakep82

|

| posted on 30/3/10 at 09:43 PM |

|

|

basically yeah. the risk is, if you go too small, the teeth may not give a strong signal, but if you do it the same size as your crank pulley for

example, it should work just fine

i say the same size, but i made the teeth stick beyond the edge of the pulley to make sure the sensor didn't pick up on the pulley itself

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

boggle

|

| posted on 30/3/10 at 09:47 PM |

|

|

ok...thats what i shall do...cheers blake....

maybe a smiley face on this one???

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

mcerd1

|

| posted on 30/3/10 at 09:48 PM |

|

|

I've got a cad drawing somewhere that should do it - have you got an e-mail ? (u2u it to me if you don't want it public)

[Edited on 30/3/10 by mcerd1]

-

|

|

|

boggle

|

| posted on 30/3/10 at 09:50 PM |

|

|

you have u2u..

thank you

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

blakep82

|

| posted on 30/3/10 at 09:51 PM |

|

|

if you can get a diameter where 1 tooth completely coveres the head of the sensor, then perfect, but still make sure the teeth are the same width of

the gaps

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

mcerd1

|

| posted on 30/3/10 at 09:53 PM |

|

|

my drawing is just based on equal sizes of spaces / teeth, the one tooth removed

-

|

|

|

boggle

|

| posted on 30/3/10 at 09:56 PM |

|

|

that will be fine....anything to help....

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

mcerd1

|

| posted on 30/3/10 at 10:00 PM |

|

|

you should have it now.........

-

|

|

|

tomprescott

|

| posted on 30/3/10 at 10:57 PM |

|

|

It's a shame that you can't use either of them, I personally prefer the look of the left wheel, would have thought that at 6mm it would be

substantial enough. Hope you get it sorted.

A bird in the hand....

|

|

|

andyw7de

|

| posted on 31/3/10 at 08:08 AM |

|

|

Drawing sent Barry

|

|

|

mcerd1

|

| posted on 31/3/10 at 08:47 AM |

|

|

I've also done a simplified 2D *.dxf (attached if anyone wants it)

its 5.125" dia. (~130mm) and has a 12mm hole in the middle

-

|

|

|