Memphis Twin

|

| posted on 16/2/09 at 12:57 PM |

|

|

English diff. preload question?

Hi all,

I'm changing from a large flange to a small flange on my English diff pinion. Unfortunately I've overtightened the little f***er (whilst

trying to do a million other things) and so now need to install a new crush spacer.

I'm trying to get my head around setting up the preload. Are the two outer bearing races free to move in the housing, or do they butt up against

a collar? Do I need to remove said outer races (or at least pull them back in the housing slightly) ready to re-install? Or is it the taper roller

bearings that are tightened against the static outer races, so crushing the spacer?

Any advice would be most appreciated!

Thanks Chris.

|

|

|

|

|

02GF74

|

| posted on 16/2/09 at 01:18 PM |

|

|

I'd have to look in Haynes manual or else think very hard in order to asnwer your quesiton.

From memory, the tapered bearing goes in and is pressed bythe crush tube when the flange nut is done up.

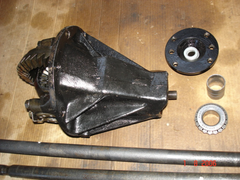

See picture here.

Rescued attachment DSC02324.JPG

|

|

|

02GF74

|

| posted on 16/2/09 at 01:24 PM |

|

|

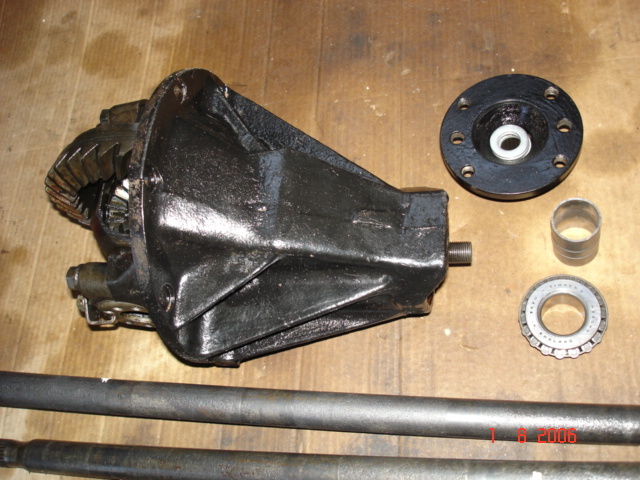

the crush tube, in between flange and bearing has 2 undercuts and a flared out section - I would guess that is the part that gets bent when you do the

nut up.

I had to replace gasket on mine so had to take the lot apart - the flange was loose indicating the nut was not done up properly.

So I am not sure if my crush tube was crushed or not.

I went with the assumption that is was so I put it over a tube and hammered the ends so they became thineer thus making the tube longer. My reasoning

was that even it I lengthened it by .2 mm, that would be enough to set the preload - it probalby take a fair bit of force to crush the tube.

To do preload - 18 lb/ft is what spring to mind - you make a little bar of known length and bolt it to the flange. Then attach spring scales at know

distance and pull - see what the scales say when the flange move and there is your preload.

remember distance x weight must be eqal to 18 lb/ft; so adjust either to get that number. It seems I used 10 ins.

Rescued attachment DSC02337.JPG

|

|

|

daviep

|

| posted on 16/2/09 at 01:51 PM |

|

|

The outer races of both bearings are pressed in to the diff housing and cannot move.

The inner bearing (closest to CW) is fitted on to the pinion after the shims for setting the tooth contact.

The crush tube is then fitted followed by the outer bearing (closest to flange).

Before the nut starts to tighten the crush tube spaces the bearings away from the races allowing the pinion to float.

As the nut is tightened and the tube crushes the bearings come in to contact with the outer races. The further the nut is tightened and the tube

crushed the more the bearings are forced in to the outer races and thus the preload increases.

If you have a small dial torque bar this can also be used to set the preload.

Cheers

Davie

|

|

|

Memphis Twin

|

| posted on 16/2/09 at 04:18 PM |

|

|

Thanks for your replies chaps. Davie, that's exactly what I needed to know - thanks for that. Haynes reckon 22lbs/ft torque to tighten the

pinion nut. I'm going to start at 15lbs and increase it by just a few degrees of rotation until it feels "right".

|

|

|

Memphis Twin

|

posted on 16/2/09 at 05:31 PM posted on 16/2/09 at 05:31 PM |

|

|

Mission accomplished.

|

|

|

MikeRJ

|

| posted on 16/2/09 at 07:16 PM |

|

|

quote:

Originally posted by 02GF74

To do preload - 18 lb/ft is what spring to mind - you make a little bar of known length and bolt it to the flange. Then attach spring scales at know

distance and pull - see what the scales say when the flange move and there is your preload.

remember distance x weight must be eqal to 18 lb/ft; so adjust either to get that number. It seems I used 10 ins.

IIRC the correct figure is 12-18 inch pounds (for new bearings), not foot pounds!

[Edited on 16/2/09 by MikeRJ]

|

|

|