Four stroke performance tuning by A. Graham Bell covers primary lengths etc in good detail, as well as diameters of the various pipes for optimal torque/power etc at different rev ranges.

very worth reading IMO

Mark

Right, I've got some 40mm thin wall (1.5mm) mild steel exhaust pipe to make my front header pipes from, how do I bend it without deforming it?

And, does anyone have any pictures of there front header pipes? Does it matter which cylinder goes where in the 4 to 1 collector? Do you just try to

get them all the same length?

Cheers

without "formers" think u will struggle, heard of people filling pipe with sand B4 bending, never tried it myself, pr-bent bends maybe yr

best option,

i go to local exhaust centers with hacksaw, they usually let you loose cutting the best bits out wrotten systems they have taken off, bends

ect..........

if yr going 4-1 then in an ideal world all the pipes should be exactly the same lengh, this lengh though for perfection can only be found on a dyno,

measure an after market system, they should'nt b 2 far off the mark.....

all IMO only btw.

The length really depends on what you want the car to do! 4-1 is better for top end power, 4-2-1 is better for mid range. If you put all the

collectors at different lenghts then you'll get power spread through the power band......

If ultimate power is your goal then measure a system, read the books and do the maths. If you just want to drive on the road i'd be tempted to

just make something that fits.

If you're trying the sand bending make sure you use kiln dried sand - normal sand is too moist and risks an explosion. Do a search on here, its

bound to have been covered.

took the words right out of my mouth.

Four stroke performance tuning by A. Graham Bell covers primary lengths etc in good detail, as well as diameters of the various pipes for optimal

torque/power etc at different rev ranges.

very worth reading IMO

Mark

I've found that bending tubing using sand & heat (the ends of the tube securely plugged to contain sand) still puts kinks (slight ones mind

you) on the insides of the bend.

For the best/cleanest results, madrel bending is the way to go. You'll need to go to a specialist with the right (expensive) tools to do this.

Worth it though.

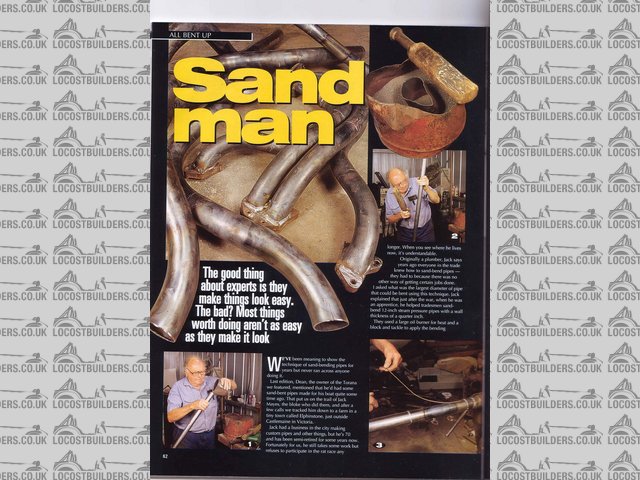

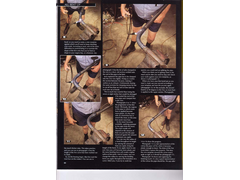

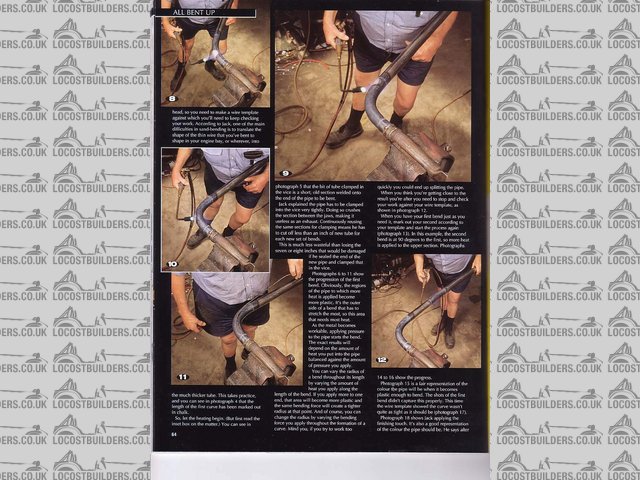

thse might help if you do the sand bending thing- sorry theyre a bit big, but they need to be so you can read the writing.

Rescued attachment sandp62.jpg

Try http://www.powerflow.uk.com/ they can help the company did my Suzuki bike

and my VEE TROUBLEYOU BEETLE and its all custom made4

http://www.northerntooluk.com/product/search.asp?k=pipe+bender&i=&action=search&x=7&y=6

[img]http://[/img]

12-Tonne Hydraulic Pipe Bender

Item No. 14420E

Bends Virtually All Types Of Pipe.6 Cast Iron Shoes For 12.7Mm To 50Mm Diameter Pipe, Top Rollers Adjust For Degree Of Bend, 609Mm L X 546Mm H X 159Mm

D, 1 Year Limited Warranty

For 96 squid cheep as chips

part 2-

Rescued attachment sandp63.jpg

part 3-

Rescued attachment sandp64.jpg

woohoo, last part-

Rescued attachment sandp66.jpg

mngogroove- those hydraulic pipe benders wont do thin wall stuff, with only having a small former, and 2 mandrels the pressure is concentrated too

much into one area and just buggers up the steel. theyre used for scaffold tube type stuff.

Russ

Suparuss thats brilliant, thanks.

<Puts on Avid Merrion voice>

I fu**ing love you!

<Puts on Lard voice>

I'm not gay or owt.

lol, no probs m8. cant remember where i found it but thought it would come in handy when i came to do me exhaust, then again ill probably take the

lazy route and use jetex pipe sections and weld em together.

Russ.

Agreed those hydraulic ram type benders are only for use with heavy duty stuff. it just kinks or creases thin walled stuff.

Where can you get these Jetex bits of which you speak? I asked custom chrome about prices for a RV8 header kit and then promply cried. That's a lot of wonga for what is a few bits of pipe!

it wont look quite as swish, but there is another way.

If you have ever seen the hotdog that used to come with a wimpy international grill, you will know.

Cut the tube in stages / segments around the bend, taking little slices out, squeeze it all together, then weld.

Thats how I did my exhaust system, but its all under the car / bonnet on mine. Might work tho......

atb

steve

[Edited on 22/12/03 by stephen_gusterson]

hmm flow might be interupted a bit by all those welds  . can get jetex bits from burton power or demon tweaks

etc should have em.

. can get jetex bits from burton power or demon tweaks

etc should have em.

oh yeah and merlin motorsport do em as well.

Russ.

[Edited on 22/12/03 by suparuss]

you're right about the welds affecting the flow, but compared to the original system it is probably missing one silencer/expansion box, plus

maybe using fatter pipes in places, so it wont be too bad IMO!

you could chop lots of little tube wedges and weld them together one by one, grinding / filing smooth the weld inside after each weld with a dremel or

something.

this would, of course, be silly.

perhaps if you were going to go the cut out vees route anyway though, and you cut the back wall close enough that you could hinge it back to clean up

the welds as you went along.. hmm.. something to consider?

but still quite silly.

yes, the flow wouldnt exactly be F1 standard, but if you are running a std road tune engine like my V6 with std contorted manifolds, I dont recon it

would make that much odds!

The sand and bending technique looks easy in the pics, but I bet its a damn site harderin real life when its yer first attempt. And it seems to use a

specialiesd torch.

seeing as (if you are like me) its all gonna be done in a std garage with bum all equipment, making up a bend out of segments may not be as silly as

it sounds.

If you dont want A1 gas flow to the nth degree, a 90 deg bend can be made up of cut segments - about 3 does it.

The very large dia tubes that form the roof of my local shopping centre are done like this. Yes - its not an exhaust, but if you are running - for

example - a std pinto and you want a simple way to make a bend in pipe in a minimal garage - is it gonna make that much BHP difference.......

atb

steve

Chaps,

Your can get the Jetex bends from....

Jetex

Agree with Mackie - CC Vey expensive. I know equipement exp. but a foot of 1.5" 16swg ERW is about 30p.

Also agree with Steve - I have a load of mandrel bends - some needed radiuses tightening, so I just cut and welded.

Not worried about weld intrusion. When I've got £500 spare, I'll get exhaust made properly.

ATB

Simon

Recently met up with 'Type 907' and his exhaust manifold is a work of art.....

Image deleted by owner

apparently it is totally smooth on the iside as well!

Dave

The only way to do it your self really is to buy some mandrel bent elbows and matching size tube and cut/weld together.

Such systems ( presuming your ok at welding) would be far better for performance and cost.

The only trouble with the previously mentioned "power flow" systems is that they are made from low quality materials/ bent on a normal

exhaust bender ( which crushes diameter of pipe) and often welded by monkeys!

Adding to that that they are over priced!

Rgds

Roger www.shinybitz.co.uk

Rgds

Roger

http://www.shinybitz.co.uk/