For ignition tuning why do we need map or TPS? I am just finishing my MJ and before I fit the TPS to the carb is there any reason for doing so? In Most performance cars on carb they do away with vacum iginition advance, its just on RPM, could I do the same on the MJ?

Your engine will run fine on 2D (ie without TPS or MAP fitted). This is what i have at the moment as i havent worked out how to fit the TPS to my bike

carbs reliably.

Fitting the load position sensor allows the timing to be adjusted so you can fine tune the car better according to throttle position - something a std

dizzy cannot do. In theory this should allow you to get smoother running, probs optimise power and i guess also improve economy depending on how you

are driving.

what he said ^^^

the MAP sensor is the beter way to achive this, but its hard to make it work well on multiple carbs (fine for a single carb)

this is why most mod'd dizzys ditch the vacum advance

a TPS isn't the best way to measure engine load, but it works and its simple and easy to fit

do a search - there are loads of old threads on this subject

[Edited on 17/6/08 by mcerd1]

my understanding was that vacuum advance is for better fuel ecomnomy and that distributors for tuned engine lose the v.a. because these engines are

fitted with twin sdie draught carbs with separate inlets so vacuum would be taken frm 1 cylinder instead of an average for the whole engine.

TPS is a workable compromise,

In do believe that a TPS can give a more resonsive throttle over a map sensore tho. This is due to the fact that it works directly of throttle

movment.

The TPS doesn't give any indication of load tho.

At 1,500 rpm on the flat 90% throttle might be full load, whereas at 1,500rpm going up a hill 40% throttle might be full load... its hard to explain

but MAP is much better to use and easier to tune.

so, am i right in thinking, if i just don't connect the MAP or TPS sensor, even if the MJ is built for either, my engine will run fine? thats

good  i can't think of a proper way to connect the TPS yet. would be nice if i didn't have to fit it

i can't think of a proper way to connect the TPS yet. would be nice if i didn't have to fit it

Yes it would work but you'd loose the major benefit of having it.

I'd try my hardest to get the MAP sencor to work, and if not resort to the TPS.

There's a few mixed responces as to weather you can get a twin carb setup (if thats what your using) to give a suitable MAP reading, we've

used it on Twin 40's by combieing 4 takeoffs into a common chamber but that hasn't worked for the R1 ITB's that were currently using.

I have gsxr 600 throttle bodys and am using a MAP sensor megajolt for the ignition.I joined all the take offs and put a mig nozzle in line to act as a

restrictor then a small vacuum canister and it works ok, it also supplys the vac sifgnal for the megasquirt controlling the fuelling.

I think MAP gives the best indication of load and the megasquirt needs a stable signal for the fuelling also, unless using alpha n. so worth the time

to get it working correctly.

Paul.

quote:

Originally posted by MkIndy7

Yes it would work but you'd loose the major benefit of having it.

I'd try my hardest to get the MAP sencor to work, and if not resort to the TPS.

There's a few mixed responces as to weather you can get a twin carb setup (if thats what your using) to give a suitable MAP reading, we've used it on Twin 40's by combieing 4 takeoffs into a common chamber but that hasn't worked for the R1 ITB's that were currently using.

thanks for the posts guys, well I am stuck wit/h a TPS megajolt so I cannot do much about map.

Just one other thing thou before I try firing up tomorrow, I am running a x-flow so the firing order is 1-2-4-3, I connect one coil to the 1 and the 4

and the other to the 2 and the 3 correct?

quote:

Originally posted by thepest

Just one other thing thou before I try firing up tomorrow, I am running a x-flow so the firing order is 1-2-4-3, I connect one coil to the 1 and the 4 and the other to the 2 and the 3 correct?

quote:

Originally posted by blakep82

i can't think of a proper way to connect the TPS yet. would be nice if i didn't have to fit it

Got it running, and first time too, started bang on as soon as I engaged the starter.

Are there any items I could use to tidy up the wiring? Other than cable ties onto the chassis?

Well done that man - good result.

i used split conduit for tidying up wiring. best bit about the split stuff is when you realise you have more wires to add later its easier to tidy

them up.

Best place ive found for split conduit is IKEA. They supply a bag full for tidying up TV wires etc - approx £5 from memory. Other than that Newark

this weekend will be good place to get some.

You could also use self amalgamating tape. Dont use insulating tape - it softens and unravels itself over time. SVA dont like it either.

quote:

Originally posted by blakep82

so, am i right in thinking, if i just don't connect the MAP or TPS sensor, even if the MJ is built for either, my engine will run fine?

Thanks Darren, I got some spit tubing, now how to I get it to hold to the chassis other than cableties?

quote:

Originally posted by MkIndy7

The TPS doesn't give any indication of load tho.

quote:

Originally posted by MikeRJ

quote:

Originally posted by MkIndy7

The TPS doesn't give any indication of load tho.

Not by itself, but in conjunction with engine RPM it does, and of course MJ measures both.

quote:

Originally posted by thepest

Thanks Darren, I got some spit tubing, now how to I get it to hold to the chassis other than cableties?

One more on the TPS, everyone seems to put it on the carb on throttle body, can I put it on the accelerator pedal? should read the same as on the throttle butterfly

Yes you can. Within the megajolt software you can calibrate the fully closed and fully open position so the sensor can be mounted on either carb or

pedal.

If mounted on pedal im not sure if you have to be careful about any slack in the cable at fully closed position. Its poss you could get some small

rotation of the sensor before the throttle starts to open. You can get around this when you calibrate by pushing the pedal a bit until cable tightens

but throttle remains closed then note the reading on the screen.

Great, thanks, installation is finished for now and I added a basic 2D map. As for the trigger wheel, I was thinking of bolting it into the pulley, at

the moment it is holding on 2 spiggots one on the side of the pulley and the other on the side of the Bolt/washer, I have only got it running in the

garage so far. Would the torque of the bolt hold the trigger wheel on the spiggots or would it move?

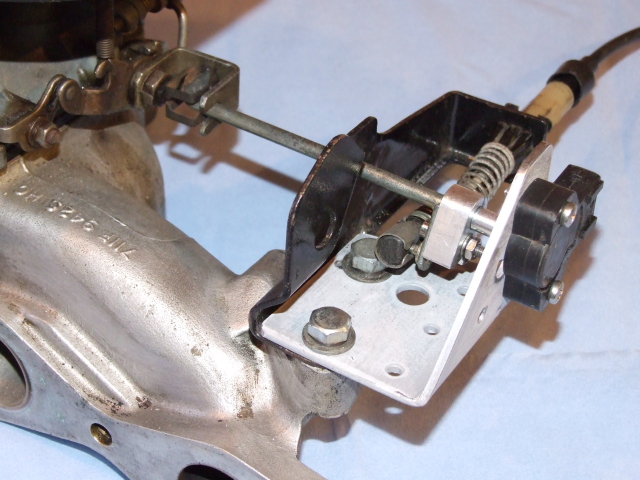

Photos:

VR sensor and trigger wheel 1

VR sensor and trigger wheel 2

quote:

Originally posted by thepest

One more on the TPS, everyone seems to put it on the carb on throttle body, can I put it on the accelerator pedal? should read the same as on the throttle butterfly

What carb are you using on the x-flow?

If it's a Weber DGV (or DGAV) down-draft then maybe you could copy what I did...

Old thread linky

My web page has further details...

Even if it isn't one of those carbs, it might give some ideas...

[Edited on 19/6/08 by David Jenkins]

Thanks to all for your posts. Couple more things if anyone is still reading this thread...

Should I need to fuse the EDIS and the Megajolt? On the same fuse or separate?

Other than mapping are there any BHP gains over a distributor type system?

Fuses were discussed on the megajolt forum - you should have a small-value fuse for the MJ unit itself (3 or 5 amps) and a higher-rated one for the

coil (10 amps).

I only fitted one 5A fuse originally, and the general opinion there was that I had been lucky not to pop the fuse up to that point.

Trigger wheel should hold with the bolt. Once you are happy with location you could drill through and tap for a grub screw or even dowel to be

sure.

Trigger wheel and vr sensor bracket looks good. Make sure there isint any movement in the bracket, if it 'bounces' you can get a bad

signal.

Probs a good idea to fuse the main feed for the megajolt, no harm in doing so. Depends where you are taking feed from and if you are going through a

bulkhead (with grommet) as well i guess.

ok all done, I fitted 3 bolts to the trigger wheel and tapped into the pulley (all at 120deg to each other to keep the balance

Fitted a 10amp fuse for the MJ will reduce it later as thats all I had around at the time, it runs ok its slightly out about 2 deg IE when it reads 10

deg on the pulley with a strobe light I am getting 12deg on the laptop throu megatune. I have the version 3 so I dont think I can do much right now.

Can I use V4 software with a V3 board?

so far running a max of 36 advance on a crossflow, will play aournd with maps later.

Thanks to all for the help!

are any of you guys using your megajolt with an xflow engine?

How did you mount the vr sensor? I can't find a decent way to fit mine.

I made a bracket that attaches with the timing cover bolts, theres some pics in my archive.

Paul.

quote:

Originally posted by drhunter

are any of you guys using your megajolt with an xflow engine?

How did you mount the vr sensor? I can't find a decent way to fit mine.

did you not see my attached photos? I used a brakcet that holds onto the bolts of the sump. Works pretty well too

haha yeah just missed that yours is also a crossflow