stroking a crank

02GF74 - 13/3/08 at 03:51 PM

is it feasible to grind the main journal off centre in order to increase the crank throw?

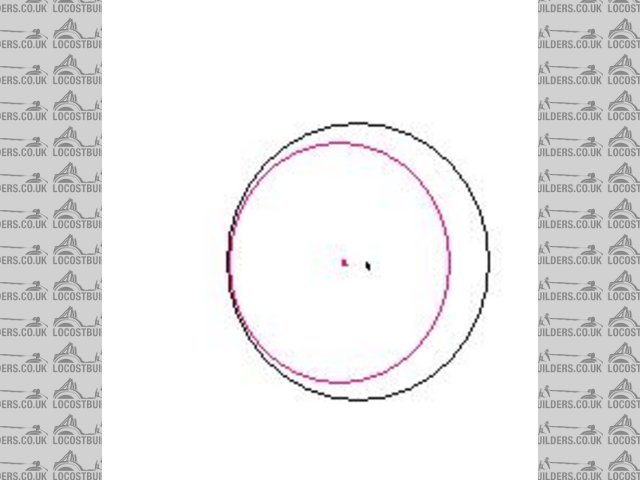

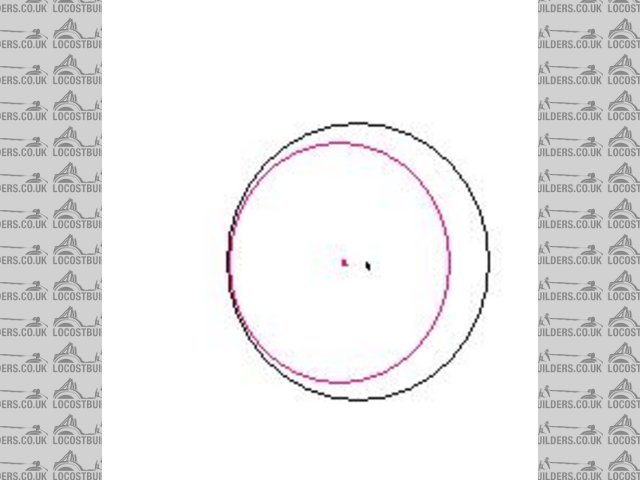

black circle with its centre is original journal and pink  circle is ground off centre, its centre is moved further out thus increasing stroke.

circle is ground off centre, its centre is moved further out thus increasing stroke.

Let's say this is a cross flow crank, an offset in the centre of 1 mm gives approx 5.6 cc per cylinder or 45 cc increase overall.

So a 2 mm offset gives us 90 cc but the journal diameter is reduced by 4 mm.

Now there has to be a limit to how small the journal can be but surely this is a way to get a few more cc?

suitable rods could be found or custom made (£££) as well as pistons.

Good or bad idea?

Rescued attachment crank.jpg

nib1980 - 13/3/08 at 03:57 PM

I'd say not as your

a) gonna be weakening a cast crank, and

b) not actually moving the effective end point of the crank, so there will be no change.

02GF74 - 13/3/08 at 04:05 PM

quote:

Originally posted by nib1980

I'd say not as your

a) gonna be weakening a cast crank, and

Agreed, a samller diameter will will be weaker but will it be still strong enough to work? Do craks fail by snapping at the big

end?

b) not actually moving the effective end point of the crank, so there will be no change.

you sure about that? I thought it moves the big end centre outwards so increasing stroke ... or am I going bonkers...

nib1980 - 13/3/08 at 04:09 PM

yep, your moving the rotation centre, but not affecting the swept volume, unless you change either the piston depth or the block height

iank - 13/3/08 at 04:10 PM

Offset crank grinding is done all the time for long (and short) stroke A-series mini engines. Costs extra over a normal re-grind presumably a the

machine needs more manual setting up

02GF74 - 13/3/08 at 04:12 PM

quote:

Originally posted by nib1980

yep, your moving the rotation centre, but not affecting the swept volume, unless you change either the piston depth or the block height

moviing centre of big outwards increases swept volume - yes, top off piston would need to be skimmed if one does not want it pushing agianst hte

head/valves

VVVVV any idea how much that would cost?

Mr Whippy - 13/3/08 at 04:12 PM

that would work, in theory but where on earth would you get matching rods? The crank would also need major rebalancing and be a lot weaker.

D Beddows - 13/3/08 at 04:35 PM

It's a bad idea as you're going to gain so little for spending quite a large amount of money. Absolutely not worth it imho - especially not

for a crossflow (and I like crossflows!)

dblissett - 13/3/08 at 04:35 PM

this is a big mod that has been done in the past on pintos iirc they use a fiester diesel conrod and off set grind the crank as the big end bore size

on the fiester con rod is smaller

this mod can get a pinto up to 2.2ltrs but its a lot of work and cost

its explained in the des hamil pinto tuning book

i feel you realy need to know what you are doing and what the crank can take.

cheers dave

jollygreengiant - 13/3/08 at 05:28 PM

Over boring and offset grinding could also be used on the old essex V6 to go from 3.0 up 3.4litres.

onzarob - 13/3/08 at 05:47 PM

It how you make a 1380 mini engine from a 1275, offset bore a standard 1275 crank and use cooper S conrods,. the bigend where smaller on on S

crank.

All parts very rare now

DIY Si - 13/3/08 at 06:07 PM

As others have said, it's easily done, and nothing unusual. I have gone the other way on my A series to get a shorter throw and such get a much

squarer engine, giving higher revs to allow it to use the near race head my engine has. It will change the characteristics of the engine, with a

longer throw giving a few less revs, but more torque, and a shorter throw going the other way. I still get 90 Lbft out of my 1338cc A series from

4-7,500, so it's not all bad!

Oh, and the 1380 mini doesn't use a different crank, it's just an off set over bore to 132 thou or so. A 1430 requires it though.

locogeoff - 13/3/08 at 06:50 PM

all these sensible replies and not one

oooerrr misses!

DIY Si - 13/3/08 at 06:59 PM

Yeah, sorry about that! Shall have to moderate the behaviour for future threads.

britishtrident - 13/3/08 at 07:04 PM

To get any worth while gain in stroke either you need to start with a brand new crank or have the journals built up by metal spraying before you

start.

You then run into the problem of ensuring the fillet radius at the end of the bearing journals is properly rounded and finished. Then the crank would

have to be properly balanced.

Just not worth the effort involved..

gazza285 - 13/3/08 at 08:15 PM

My steel Crossflow crank is offset ground. It's a 1300 narrow journal crank which I got of MemphisTwin, it now runs CVH rods which have a smaller

big end, slightly narrowed to fit the Xflow journals, and Lotus Twink flat top pistons. Cost £125 to have it ground, filleted, renitrided and

balanced. Needed grinding anyway and it doesn't cost any more to have them offset ground. Gained just short of 4mm stroke.

NeilP - 13/3/08 at 08:17 PM

quote:

Originally posted by locogeoff

all these sensible replies and not one

oooerrr misses!

I read the title of the thread and thought I'd clicked into a different (ahem) site!

brynhamlet - 13/3/08 at 09:12 PM

Talk to Newark engines at Sutton-on-Trent.

My engine block is formula ford, with lightend and balanced crank. They have worked out how to take a 1600 ford OHV out to 1800cc without all this

fancy grinding of cranks. By overboring the engine, g*d knows how, I can now rev the engine out to about 7500RPM, instead of maybe 6000RPM and with

the other things they built into the engine it develops a hell of a sight more power than it originally did. It certainly puts out more than 120BHP

and when I get it on a rolling road, I'm sure it's more.

snapper - 13/3/08 at 09:41 PM

Offset grinding needs a plan... i.e conrod length piston height, block deck height and crank offset all planned for your required result.

possibly on the pinto you could off set a bit to increase compression and capacity as the piston top to deck has about 1mm or so to play with.

If you had V6 pistons on standard rods then you have more to play with before the piston gets to close to the deck height.

The pinto crank is strong so will take a hefty grind safely even well below the minimum oversize grind, thats why you can fit fiesta diesel con

rods.

But you have to get your maths right and also any increase in stroke means more torque but less revs so cams start to come into the equation.

However overall, I agree, a bit more capacity for little work is always a good thing and if you have an engine apart then a little more spent on this

sort of thing is worth while IMHO

Macbeast - 13/3/08 at 10:07 PM

Colin Chapman did this in 1952 to reduce the 1508 Ford Consul engine to compete in the 1500cc race class. Crank was ground eccentrically and oversize

big end shells fitted.

thomas4age - 13/3/08 at 10:24 PM

loads done that to acomodate yamaha XT500 pistons in a Pinto engine, uses VW GTI rods

can be done but requires a lot of think before the grinding can begin, looks like a nice project! you can calcuulate yourself and have an engine

rebuilder grind the crank to your spec, that's not even that expensive, I recall 70euro's per big-end over here in holland, 200 pounds

should have the new shells sorted aswell.

maybe a MC piston can be fitted to reduce a LOT of weight.

grtz Thomas

iank - 13/3/08 at 10:55 PM

quote:

Originally posted by onzarob

It how you make a 1380 mini engine from a 1275, offset bore a standard 1275 crank and use cooper S conrods,. the bigend where smaller on on S

crank.

All parts very rare now

1380 A series is a 73.5mm offset bore with a standard crank, it's now the standard big bore mini size (for those that won't swap the engine

to something more modern).

The 'common' long stroke A-series is 86.5mm giving 1430cc from a 73.5mm overbore

Short stroke is 79.3mm giving 1285cc or 1299cc and are used to get both a big bore/high rpm while staying within 1300cc for events that class break

there.

Not many people bother though.

circle is ground off centre, its centre is moved further out thus increasing stroke.

circle is ground off centre, its centre is moved further out thus increasing stroke.