New pinto head, work in progress

flak monkey - 2/8/07 at 05:20 PM

Got an unleaded head for the pinto so been working on that when I havent been out in the car.

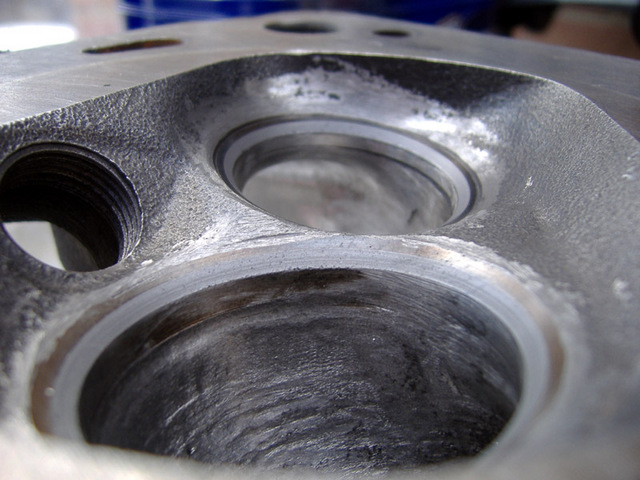

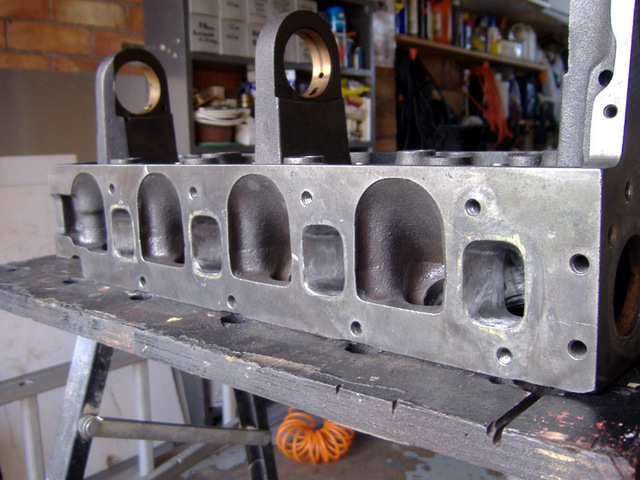

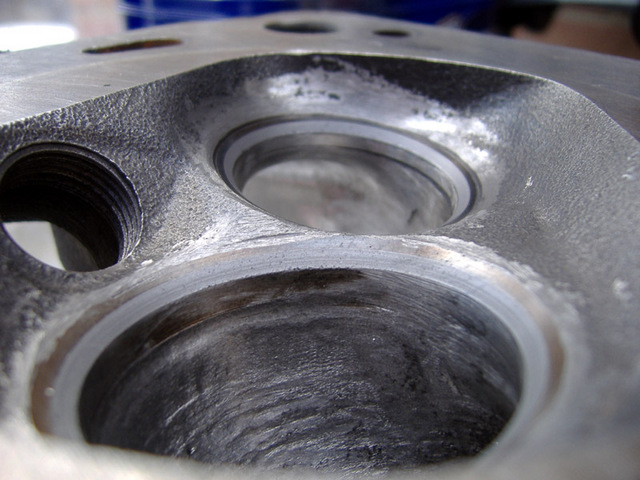

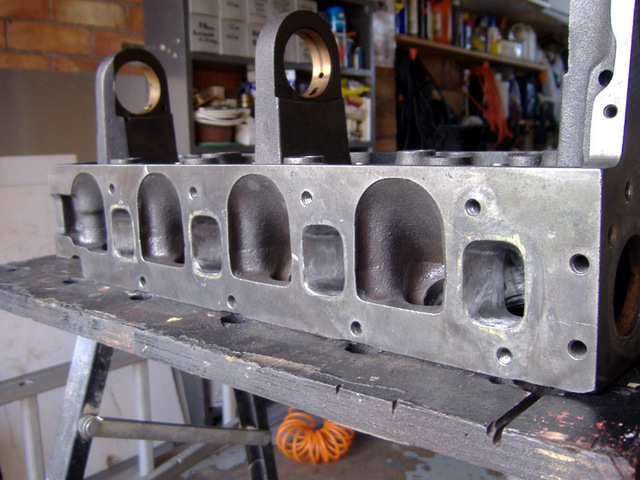

The exhaust ports have been fully opened out to match large bore exhaust gaskets (ignore the yellow paint pen, I use it as a base for marking out on).

The cross sectional area of the port has been increased all the way back to where it begins to turn into the valve throat.

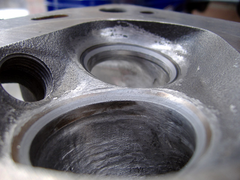

Both the inlet and exhaust valve throats have been opened out, which has reduced the width of the valve seats. The valve guides in the ports have been

streamlined and slimmed up, especially the exhaust one, to reduce their restriction. I have left the guides in the ports as it is essentially a road

engine, and I need reliability/max life. The counterbores around the valve seats have all been removed.

The inlet port was left as cast. The valves have been lapped in, all threads cleaned out with a tap and the whole head been pressure washed. It will

be fitted with a new Kent FR33 cam kit, which is a step up from the current FR22, unfortunately I couldnt stretch to big valve and a Piper A8.

The head gasket will be a Felpro Blue which is slightly thinner than the standard one, giving a slightly increased compression ratio.

New cam bearings have been fitted too.

The head will be swapped in a couple of weeks, then the car will be taken to the rolling road and set up and I will also get BHP and torque figures,

which could be interesting.

New head build

New head build

New head build

[Edited on 2/8/07 by flak monkey]

matt.c - 2/8/07 at 05:23 PM

you want more power!!

DIY Si - 2/8/07 at 06:09 PM

You always need more power!

Looking good there Flak. You not been tempted to play with the combustion chambers at all?

jacko - 2/8/07 at 08:46 PM

Flak that's looking good why dont you get it planed it makes a difference it power

do you have the book how to power tune a pinto by Des Hammill its very good

Graham

jollygreengiant - 2/8/07 at 08:55 PM

I would fit valves & plugs. Then measure the cc of the combustion chambers and grind each chamber to the same cc. This would balance the power

across each cylinder.

THEN I would have the head face planed to up the compression ratio.

Looks good.

TangoMan - 2/8/07 at 08:59 PM

It's a good start David. I do hope you are going to tidy up those throats a bit more and radius the seats in at each end.

I would also get it skimmed (I can't remember how much) as you want to raise the compression to around 10.5:1. As you go with wilder cams you can

run more compression as you lose some effective compression at low speeds due to valve overlap.

Extra compression will give advantages in both performance and economy and is well worth the cost while you have the head stripped.

Other than that, it looks good.

Is it an injection head or just an unleaded one. The injection head has better (smaller) inlet ports with a steeper run down to the back of the valve.

Jon Ison - 2/8/07 at 09:08 PM

The best pinto head i had actually had material add'd to the inlet ports, it was a "Dave Brookes" head and came out of at the time a

very competitive escort rally car.

Material was added to the bottom of the ports to make it "downdraft" as he called it. The inlet mountings where raised accordinally.

[Edited on 2/8/07 by Jon Ison]

TangoMan - 2/8/07 at 09:26 PM

Adding material used to be the trick to improve the flow of the poorly designed Pinto head. With the injection head Ford learned some lessons and

improved the downdraught as well as shrinking the inlet port.

I can't remeber the figures but the later head is worth quite a few horses over a standard one and has better tuning potential due to raised port

angles.

I bet that head cost you a few pennies John. Dave Brookes heads were not known for being cheap!!

flak monkey - 3/8/07 at 06:03 AM

It started life as an injection head, so it has the better shaped ports to start with. Which was, according to ford, worth another 15bhp over the

standard carbed engine.

IIRC a 40 thou skim should do the trick?

DarrenW - 3/8/07 at 07:58 AM

Looks good David. Similar to what i have done before. I dont believe that head would have been skimmed before as allegedly it came from a low mileage

engine in a granada injection. I skimmed mine conservatively at 40 thou. Des would say you can go to 60thou but i dont know if the higher compression

would give other unknowns.

FR33 should make it sing.

C10CoryM - 3/8/07 at 02:11 PM

Looks like you are going about it the right way. You may want to smooth the edges where the chamber meets the quench area. Nothing exciting, just

round it a little bit to reduce the chances of the edge getting hot enough to ignite the mixture.

NS Dev - 3/8/07 at 02:18 PM

Seen a lot worse that people have payed good money for, not a bad effort if all the ports are the same.

As others have said, while the head is in bits, get some old valves and cc match the chambers, makes it a lot easier to set the ignition up when they

all pink at once!

Then skim it, no idea how much, again do the maths (fill the chambers and a stuck on used gasket, then ratio to the swept volume), get your head mill

chappie to take a ten thou cut, get him to get on with another job while you measure again, then multiply up to get the actual skim amount.

As with every engine build job, its a pain in the a but thats why good engines cost good money!

flak monkey - 3/8/07 at 05:11 PM

Looks like the head will be getting swapped sooner than planned.

#4 lobe and rocker (cyl 2 inlet valve) on my current set up are wearing at an alarming rate - as in the cam is now knackered. Not sure whats caused

the problem. The oil feed is good (checked with rocker cover off - messy but proved a point) and to my knowledge the valve guide and stem are in good

order - they certainly were when I built the head and they werent tight in the least. I have heard stories of soft lobes/hard rockers before now, but

both seem to be knackered... New rockers were fitted, the cam was a low mileage FR22 with no visable wear.

My new cam should be here on monday (I hope), if its not I dont think I will make the p'boro meet in the GTS.

The car is now stuck in my garage awaiting the new head, dads going to give me a hand to get it swapped as soon as its ready. Also got hold of an

82deg thermostat