thanks

Rescued attachment poly mounts.jpg

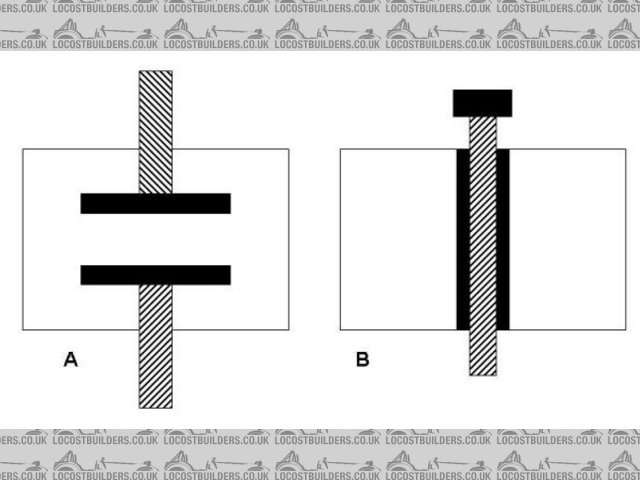

I have been using the 50mm tall transit / landrover type engine mounts from Rally Design with my zetec / tiger, but they seem to get soft quite

quickly (quite a bit of engine movement new compared to when they were new 12 months ago). Does anyone know where I can get some polyurethane or nylon

mounts from that look like diagram A below (M10 mounting bolts). Or should I just buy some polyurethane / nylon rod and make some stainless steel

sleeves up so the mounts look like diagram B ?

thanks

Rescued attachment poly mounts.jpg

thanks Chris,

yes I'm using the group N mounts. They were fine when I first got them but now seem to be getting a bit soft, hence the polyurethane / nylon

idea.

If you do dia B but bin the inner tube, you'll be fine. Otherwise it'll just clamp down on the tube, and pretty much solid mount it.

Havent used them myself but these people were recommended to me:

http://www.rino.co.uk/products.asp?category=Anti%2DVibration&subcategory=Anti%2DVibration+Mounts&gclid=CKLZnsPt6IsCFSYSQgodDxhZVA

quote:

Originally posted by DIY Si

If you do dia B but bin the inner tube, you'll be fine. Otherwise it'll just clamp down on the tube, and pretty much solid mount it.

I'd be careful with the Grade of Nylon/polyurathane that you get.

The engine mounts for my Tin-top were specialist ones and they would only sell you the full kit (when only 1 was split!).

We went to a local Plastic suppliers and they said "yes we've got just the stuff they use this on the Focus WRC car" and my GOD could I

believe it.. the engine might as well have been bolted to the chassis it shook everything!

Whatever the hardness its measured in I think that was 90 and what i've got now is about 40-50 and its still far too hard really the engine still

doesn't really move when rev'd or when load is put on it.

I'd try and stick to something commercially available as Engine mounts