P.S this is another locost build and my preferred engine is the zzr1100 but smaller units may be easier to fit

Rescued attachment bits 035.jpg

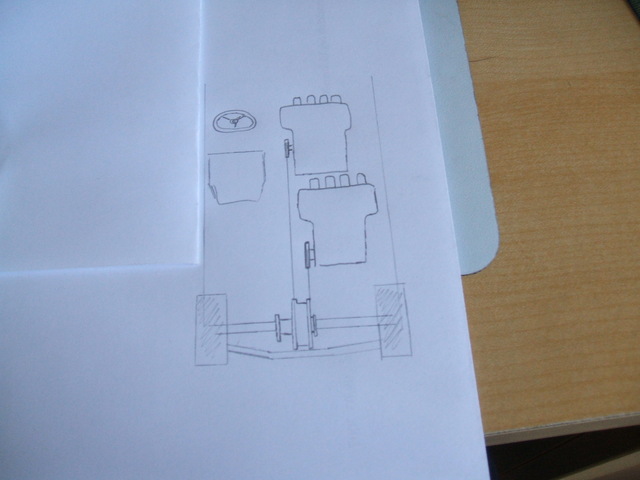

ive just bought a left hand drive kitten from holland and have done a little sketch of how i want to mount the engines, i cant see any problems as i

have a 3.62 lsd diff to form the basis of the chain drive and have some measurements of the engines i want to use but i may have overlooked something

so any suggestions please

P.S this is another locost build and my preferred engine is the zzr1100 but smaller units may be easier to fit

Rescued attachment bits 035.jpg

A bloke I know builds grass trackers and that's how he did the VTR1000 engined Cinquecento that I was looking at in his garage a couple of years

ago....

i presume they are chain drives to the diff, i would be concerend about the length of these esp the front engines could you not use two shorter chains

to a central shaft behind the engines and a shorter single or double chain to the rear to keep the chain runs shorter.

i,m sure i saw a grass buggy with a similar setup at Autosport this year.

Rich

i think that although the chain runs are on the long side it will be easier to make the adjustment on the diff mounts than have to adjust two sets of

chains, i have to do my kitten van every time i go out in it but to be fair the chain is tired on it.i had though of a jockey wheel on each chain run

to compensate for the length.

i cant see any other issues than the length of the chain for the front engine and if i can find a bigger die for my tube bender i might be able to

butt the engines closer together if i can get the exhaust on the rear engine out of the way. i already have a zx10 donor and going on the weight of my

van i should be on for 600kg and 280hp

here she is[img]http://locostbuilders.co.uk/upload/a524736-kitten20030418[1].jpg[/img]

Certi - bleedin - fiable... ;^)

Is the robin mobile yet?

cheers

Bob

Am I right in thinking, one of the big issues with twin engine set ups like this is being 100% of getting the gearchanges in sync, and the longer the

linkage the bigger the risk.

I guess one running in a higher gear than the othe would soon make a bang!

Love it!

What about belt drive?

Would the chain length be a problem if it was supported?

A lad at Uni made a Baler(? - collecting hay bales round his farm) and because of the size of it he ran a really long chain and to get round one of

the problems the chain ran on two strips of hard nylon, I was thinking something along the same lines for you (although paired up obviously!) even

though the horsepower is not at all relevant as is the speed the chain will pass over the nylon?

atb

Steve.

im thinking of using a couple of front sprockets and some spring tension to keep it from flapping around. as for the gearchange it would have to be on

cables and as long as the levers and pivots were the same it should work .

bob, i think i will need some bearing blocks for this one as i dont think i can drive it with a solid diff

the thunder pig will have its prop back this week then a bit of bracket work before the body goes back on

Whilst I love the idea and concept, I would bare my *rse in public before I would sit next to a drive chain of that length!!!

Surely you will make a cover for it?

i can only think of two contributions, one good and one half baked.

Using slipper clutches would (i believe) prevent one engine pushing the other through its red line in the case of gear mismatch.

And possible it would be better to use belts rather than chains? Not very locost if you can do the chains yourself cos i guess you need a specialist

for belts, but they are quieter, lighter and have less losses i believe, and are surely less likely to break. Also easier to get a tensioner onto it.

please tell me your gonna drive round with them steel wheels on. baiting the chavs pmsl

that will be quick as f*** when done ill pay you to take me for a spin in it lol

That will work fine froggy.

Your issue won't be with the long chain being too long, but more the short one being too short.

You'll find the short chain is pretty short lived, but it will certainly work.

You could do one engine above and slightly to the rear of the axle, and the other in front, would give a nicer setup, but you would need a stepoff for

the rearmost engine drive to clear the end of the engine.

No clutches etc needed for linking the engines, just use a pair of cable shifts and adjust it so they shift together, nowt tricky about that.

Take it you're using an lsd on this one??

Only issue I can see is that you'll need to be able to move one of the engines to provide separate adjustment on both chains as they will

obviously wear at different rates, moving the diff will adjust both the same. My twin ZX10 gearshifts are by mechanical linkage & work fine,

occaisionally you'll get a false neutral & missing a gear can result in being in ,say 2nd on one engine & 3rd on the other but providing

you don't take it past the redline on the engine thats in the higher gear it causes no problems with driveability (bike gear ratios are very

close anyway once your into 3rd or above).

Good luck with it, you should have similar power to weight to mine, but slightly more understated looks!!!

i dont no if this idea would work but couldnt you use two sierra diffs one engine driving each diff and join the two inner diff shafts together and

use the two outer ones for the wheels just an idea

adam

the inner pair of shafts would just spin freely

i think the plan will be to fix the engines and use a sprung tensioner on each chain run to keep the chain sort of tensioned and make the same

adjustment set up as i have on my van. im hoping that the engines will start about level with my knees and end a little bit behind my arse,

unfortunately icant run this one on 10"wheels as it really does need to stop properly but iknow that z-cars made some front uprights for my

mate,s zx10 powered kitten which take ford brakes and my de-dion jig is set up for ford hubs on the back , this is new territory for me as i think

this will cost over 2k to build

Re bearing blocks etc. if you need some lathe time just give me the nod

Bob

quote:

Originally posted by russbost

both the same. My twin ZX10 gearshifts are by mechanical linkage & work fine, occaisionally you'll get a false neutral & missing a gear can result in being in ,say 2nd on one engine & 3rd on the other but providing you don't take it past the redline on the engine thats in the higher gear it causes no problems with driveability (bike gear ratios are very close anyway once your into 3rd or above).

!!!

quote:

Originally posted by Bob C

Re bearing blocks etc. if you need some lathe time just give me the nod

Bob

the closest thing i have to a lathe is a nine inch grinder

the closest thing i have to a lathe is a nine inch grinder

quote:

Originally posted by ReMan

quote:

Originally posted by russbost

both the same. My twin ZX10 gearshifts are by mechanical linkage & work fine, occaisionally you'll get a false neutral & missing a gear can result in being in ,say 2nd on one engine & 3rd on the other but providing you don't take it past the redline on the engine thats in the higher gear it causes no problems with driveability (bike gear ratios are very close anyway once your into 3rd or above).

!!!

This is the point I was trying to make.

How do you know one is in the wrong gear though?

How do you fix it, do you have to get out and waggle the shift for the one engine to re-sync them?

Cheers

quote:

Originally posted by froggy

quote:

Originally posted by Bob C

Re bearing blocks etc. if you need some lathe time just give me the nod

Bob

cheers mate but i may need some tuitionthe closest thing i have to a lathe is a nine inch grinder

i have to admit this one is relly getting my juices going ,so much so that i may sell my v8 4wd project to fund some more monstrous engines maybe a

pair of zx12,s . i think yours is about as silly as mine but there isnt a lot in it

. i think yours is about as silly as mine but there isnt a lot in it have you any forecast on the weight for yours? i should be

between 575 -600 realistically

have you any forecast on the weight for yours? i should be

between 575 -600 realistically

about the same for mine I'm thinking, hopefully mid 500's

bought the first donor today a snip at £1500 and will recuop a good chunk back in bits

Rescued attachment r1.jpg

donor its mint you got that for 1500

[Edited on 22/3/07 by oadamo]

you'll be useing a lathe in no time im sure, there pretty basic tools once you understand the calibration and a few other things

[Edited on 22/3/07 by goodall]