Would I get any noticeable power increase if I have a go at grinding the inside of the inlet manifold out and polish it down in an effort to move the

air faster?....

Its the 2 litre intake with twin choke webbers...lightened engine etc..

Any thoughts?

Dunc

I believe the concensus of opion/fact is that if you polish the ports there is no noticable improvement in air flow over a normal ground finish. David

Vizard discusses this in one of his tuning books and goes to great lengths to test the effectiveness. A well ground head that is shaped to flow well

is all that is needed. Of course, a shiny polished internal surface looks cool though

Remove all sharp edges or obstructions, but as for polishing, its generally regarded as no need to go smoother than 80 grit (with some WD40) for manifolds and ports.

Yup. Totally agree- its not the polishing that does anything (can make things worse) its the removal or ridges and obstructions..... Removing casting lines is okay, anything else isn't worth it unless you've got a flow-bench so you can see check what difference you're making. If you take it too far with removing material things start flowing worse and power goes down..... At least if you have a flow bench you can find out when you've reach optimum....

shiny surfaces can make the fuel condense on the surface if the air/fuel mixture is warmer than the manifold so is a no go.

Also apperently the polishing allows fuel to form droplets on the surface better than a rough one, which you don't want. If you dowell the

manifolds (to insure repeatable line up) and feel down the ports you should feel no difference between the manifolds and the head, porting this is a

good idea also 3 angle seats are a good idea. The area within half inch or so around the valve is the critical area, i blended the valve stem into the

valve support being careful not to damage the valve guide, you can remove the valve support but this shortens the life of the head, i am also running

a fr32 cam which is still roadable. hope that covers it

you want to match the ports - maifold to head and m/fold to carbs - use gaskets at each end for matching.

you can make the port the air is flowing into (head and carb side of manifold) can be a touch bigger but a step in the other direction is not so

clever.

you will find the surface have lumps/bumps/bulges etc - get rid of those.

of you are keaan, then polish the surface - I did - it is a bit old school - the new school of thinking is to have it smooth and the matt finish -

reaso is smooth surface collects minute fule droples whereas they bounce off a matt slight rough surface - peersonally I don;lt think you'll

nitice the difference; a polish surface is less likely I t hnk to pick up crud.

I use a hand file and a dremel type tool with a oval shaped metal cutter - good for ali but not for iron/steel. then finish off with sanding discs

and fianally wet'n'dry .

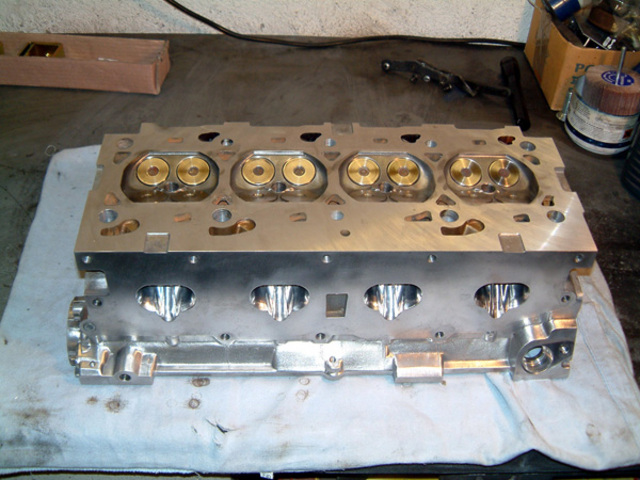

here is 1 I made earlier, albeit cyl head before, showing marking out

v8 inlet before

and after (not been polished mind).

v8 inlet - after

Sound advice - polish exhaust ports and manifolds inside, but not intake manifolds/ports. Smooth(ish) is okay, but a really shiny surface creates a stationary layer, where fuel will (as mentioned by suparuss) condense out on the inner surfaces, really screwing up your mixture. A slightly rough texture breaks up this layer and helps to atomize the mixture properly...

This is a nice way of polishing oure ports:

http://forums.audiworld.com/a4/msgs/1567770.phtml

Interestingly, my ST200 upper inlet manifold is 'extrude honed' to improve gas flow, which basically means an abrasive paste is forced

through the airway path to polish it. Ford reckon it really improves performance.

Just my 2p

i enjoyed doing this took me a full 8hrs

Rescued attachment DSCF0375.JPG

As zetec7 said, a polished surface will tend to cause a stationary layer of mixture between the tract wall and the main flow. this is due to friction.

If the tract is left with micro grooves due to grinding, these little tiny ridges cause micro annular vortices and this effect is like having a

tubular roller conveyor for the gas flow.

Nice job thunderace!

[Edited on 11/1/07 by Confused but excited.]

According to Guy Croft's book, he back-to-back tested a polished and bog-standard inlet manifold for twin 45's and found that the boggo one

actually flowed better that t'other one

The only bit of advice I would question here is the matching of ports.

It has been found that mismatched ports (the correct way) can aid performance.

Especially where wild cams are used, an inlet face smaller than port and exhaust face larger than port can help to reduce the reversionary effects of

valve overlap without any negative effect on performance.

Obviously if you get the mismatch the wring way around then airflow would be interrupted causing a reduction in flow.

Certainly, having the exhaust manifold larger is wise. This helps to stop any flow reversion from wide overlaps.

ok this opens a can of worms i have moded a few heads in my time. i will assume you are using a pinto. you can only do so much of the work your self

unless you know some one with a valve seat grinder and a valve grinder.

with the pinto head you will need 2 replace the valve guides this makes the valve more stable and intern it seals better also if u use bronze valve

guides you can have a tighter fit this will aid in better heat transfer from the valve to the haed.

The pinto ports ar quite big so not much grinding is needed. try to stighten out the port a bit and remove anything that will diflect flow. do not!

remove all the valve guide that comes in to the port shape it like

wing shape this will assist flow round the valve.

puting bigger valves in and 3 or 5 seat cut is best left 2 them with the right equipmen.

when grinding ports to mach on the intake leave the manifold 1mm smaller all the way round this will let gases flow in ok. but when you get blow back

it hits the ledge and stops it a bit and this stops it upsting your carbs. just mach the exhaust.

do not grinde your valves in for ever and a day if you use the valves you allredy have this will dome the seat and thay will not seal as good. get

them cut and the valves ground and just grind them in. 10 sec a valve.

Sh@t, think i should of asked for some advice before i spent weeks doing this then. What makes it worst is , by the sound of, i've actually made

it worse

Description

Oh well we live and learn

i woud just get a 150 paper and create turbulence...

also it looks nice in your photo books

bling bling..

TKs

i allso frogot to say hve the head skimed allso have the top face done to and make sure the valve spring seats are all at the same hight. when the

valves are seated make sure the tops of the valves are all at the same hight.

btw what head are you useing and i may be able to give you some more advice. eg valve size and seat angles.

just anuther thort what head gasket are you useing. if you are using a standard type i would opt for a milled finish if it is a copper one iwould go for a ground finish if it is a very thin steel one have it groung and then have it checked on a surface plate and hand scraped in if needed.(dependes on how good there grinder is)