Sealing my bl00dy exhaust!

gingerprince - 21/8/06 at 09:01 AM

Okay getting annoyed now. My MK has a custom 4-2-1 Tony Law exhaust system. The big problem I have is I cannot no matter what I do get the headers

to seal to the pipe!

It's 4 separate equal-length pipes that come from the engine and feed into a 4-2-1 collector. The problem is that there's _no_ space

between any of the collector ports so I can't clamp in any way: -

OO

OO

Looks like that from the front. There's NO gap at all between the 4 ports.

I've resealed it several times now using different methods and it just doesn't last!

I've used fire gum, but it just vibrates itself out. I've tried silicone, but if I put too little on I don't get a seal, if I put too

much on it gets blown through from the inside due to the excess.

I've got some of that orange instant gasket, but I suspect that'll be just the same as the silicone. I've got some exhaust repair

putty, but I suspect that'll set hard and vibrate out like the fire gum does.

Any tips on how I can get the blumming thing to seal? For example can you buy heat resistant rubber tubey gasketty things or such like?

Any ideas please? Getting bored of dismantling and assembling my exhaust again and again!

Thanks

nitram38 - 21/8/06 at 09:14 AM

Can it be welded?

Some photos would help!

zzr1100rick - 21/8/06 at 09:14 AM

is it possible to have it welded ?

if the joints have a half decent depth of engagement and are tight they should seal

muzchap - 21/8/06 at 09:19 AM

If it's like mine - the whole reason I have the 4 - 4-21 system as GingerPrince - is so that my exhaust can exit the aluminium side panel and not

the bonnet.

Welding mine would make it impossible to fit - perhaps Ginger Prince's is the same?

How about welding a bead around the diameter of the pipe and getting a lead/copper (or whichever metal takes the heat) o-ring to squash up against -

that should offer a pretty good seal?

I think it's an inhernet design flaw with these systems - I have trouble with 1 pipe not sealing - but hardly notice it now

indykid - 21/8/06 at 09:29 AM

you say if you put too much silicone on, it gets blown through from the inside, but does it seal?

surely it'll just get blown through the can, and exit with the gases, or blown a bit further down the pipe?

if it doesn't work, it doesn't work, but i'd try that again before anything else.

tom

Guinness - 21/8/06 at 09:31 AM

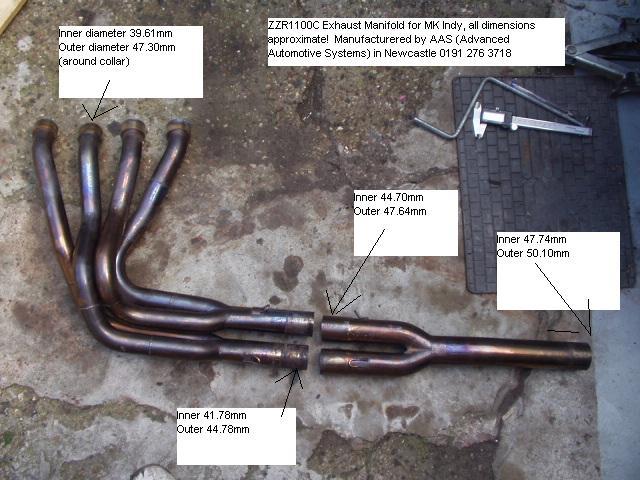

Mine is a 4-2-1 system made by AAS in Newcastle. They hold their systems together with little loops welded to the two parts and connected by springs.

Not very SVA friendly, but after 1700 miles it was sealed VERY tightly. Every time the system heats up the springs pull it tighter. When it cools

down it squeezes it shut.

Hopefully you can see them in this photo.

zzr 1100 manifold

Perhaps you could get someone to weld some onto your pipes?

HTH

Mike

cadebytiger - 21/8/06 at 09:39 AM

I know this may be a silly question but what is the problem with them not sealing? Is it just the noise?

Rupert

02GF74 - 21/8/06 at 09:43 AM

quote:

Originally posted by gingerprince

I've used fire gum, but it just vibrates itself out.

ok, this sounds like 4 into 1 exhasut systems on motorcycles - so how do they get theirs to seal?

Now it was mentioned, I do recall having the small loops and springs on my z1000 and using fire gum.

how much overlap do you have into the collector? if there is a lot then the whole thing will be more rigid so won't vibrate?

is the rear clamped too tightly so it isn't able to move & is the engine/front moving about too much? <-- basically what I am saying is

to reduce the relative movement beween the too - maybe put a support as close as possible to the 4-way joint?

finally would a jubillee clip fit over the joins - maybe that would stop them from moving relative to one another - woulnd't look neat though.

Hellfire - 21/8/06 at 09:51 AM

I love the idea about the springs however it is a bit of a eyesore and as you say not very SVA friendly.

We have a similar problem and as we see it there are a number of reasons it does this.

1. Expansion/Contraction breaks the seal.

Solution is to flexibly mount the can end to allow the Ex/Con of the system to be accomodated without breaking the seal. Typically these systems are

solid mounted engine end and rubber grommet the other... this isn't good enough for a sealed system as the grommet does not allow for enough

movement. Our solution was to place a reinforced rubber strip on the can end and fixed to the side panel... this allows for fore and aft movement

required but not lateral movement which could cause knocking on the side panel. We have not applied this due to holidays but is a suggestion to solve

this common problem.

Welding up the collectors will work for a short time until the Ex/Con breaks the welds again... it is almost impossible to weld up a 4-1 or 4-2-1

collector completely.

I hope this sheds some light on this matter and brings about a solution...

Steve

James - 21/8/06 at 09:51 AM

quote:

Originally posted by gingerprince

For example can you buy heat resistant rubber tubey gasketty things or such like?

Yes you can, my mate's Blackbird had them. I remember as they were a right pig when we were putting the original cans back on when he sold it!

Cheers,

James

gingerprince - 21/8/06 at 10:34 AM

Thanks for all responses. Answers in order of posts: -

I'll get some photos tonight.

I'm not sure it'd be possible to get a good weld, getting into the "middle" bit might not be possible.

There's between 1 and 2 inches of depth from memory.

With the silocone "blown through", what i mean is it basically blobs up inside when I slide it together. When it's all set the exhaust

gasses blow against the blob, which eventually gets thrown out the back - taking the remaining sealant with it so it blows once more.

It's not held together with springs, but the collector is bolted to one of the down pipes to hold them securely together. A photo will show what

I mean.

The problem with the sealing is firstly it's noisy (not good for track days etc), but also I assume a blowing exhaust is an MOT failure - and

that's due October.

The can is kindof flexibly mounted. It basically rests on a U shaped frame with 2 long springs around the top. However whilst this is more flexible

than solid bolted it's by no means easily movable - I may look into an alternative method for this.

Hmmm might be worth me trying to get hold of some of those "tubey gasketty things" too. If they were a pig to take off, presumably they

were sealed well then

Aboardman - 21/8/06 at 11:20 AM

what about

http://www.greenham.com/c/pl/69181/Firestop-400-Acrylic-Sealant

to seal it, B&Q should sell something similar.

paulf - 21/8/06 at 11:31 AM

Ive used that and had good success on a can end cap when repacking my silencer.The only problem may be it does not set fully hard and may still blow

out of a collector joint but definetly worth a try.

Paul.

quote:

Originally posted by Aboardman

what about

http://www.greenham.com/c/pl/69181/Firestop-400-Acrylic-Sealant

to seal it, B&Q should sell something similar.

[Edited on 21/8/06 by paulf]

muzchap - 21/8/06 at 12:25 PM

Oops should add mine has springs to hold it together - and seems to work pretty well

Mike S - 21/8/06 at 01:41 PM

I have a custom stainless exhaust on my GT1 which was very nicely made by Powerspeed near Ashford.

I queried the fact that the headers were only a slip fit into the collector as I was worried about leakage in this area.

Dave Parris (top guy) said that they might blow a bit when cold, but as the headers warm up they expand into the collector and seal tight.

Sure enough, they do just that.

I asked about firegum etc. Dave says its not needed, and in any case it would get blown back into the V expensive Cat and knacker it. So dry fit it is

for me.

Hope this is helpful.

Regards

Mike

JB - 21/8/06 at 04:09 PM

I had the same dilema. I wanted to be able to split the manifold but still get an exhaust tight seal so I made flanges.

I then used some high temperature gasket top seal them.

John

zetec7 - 21/8/06 at 05:48 PM

Weld a couple of small hooks onto each side of the joint (one on top, one on the bottom of each side of the joint), stretch a spring between each of

the hooks (as per race car fashion), and you're done. Stout springs should give you a tight seal that you can still separate if you need to.

Syd Bridge - 21/8/06 at 07:08 PM

Partco sell some stuff in a tube, same size as the big cartridges of other sealants. About £4/tube, and it's what all the exhaust fitters use.

We used to have to hammer the joints apart on the youngsters race car.

Cheers,

Syd.

gingerprince - 21/8/06 at 08:25 PM

Here's some pictures, should show the setup I have well enough.

I don't think spring etc will work because that assumes that it's holding the pipes up against a flange or something, but that's not

the case here. The pipes overlap by about 2 inches, but just pushing them in any harder doesn't seal. I just don't think the

"fit" is tight enough - when I mate the pipes there's an amount of "wiggle", which is why I need the right kind of seal

rather than just a push-fit.

More Pictures Here of the setup

Peteff - 21/8/06 at 11:35 PM

High temp silicone exhaust sealant, Draper do it in small tubes and it stays flexible. Clean all the soot out and just use enough for the job.

02GF74 - 22/8/06 at 08:04 AM

quote:

Originally posted by gingerprince

I don't think spring etc will work because that assumes that it's holding the pipes up against a flange or something, but that's not

the case here. The pipes overlap by about 2 inches, but just pushing them in any harder doesn't seal. I just don't think the

"fit" is tight enough - when I mate the pipes there's an amount of "wiggle".

stupoid question but have you spoken to the manufacturer?

re: springs - I have no flanges on my bike exhasut so there

To make the fit tighter, the way I would do it is to stick a large tube in a vice and put the exhaust tube - the one the slides into the larger

diameter tube - over it and hit gently many times with a hammer.

This will enlarge the tube by squashing the metal.

Practise with some scrap tubing first.

procomp - 22/8/06 at 08:21 AM

Hi i got fed up of the rattaling sound on a tony law manifold so i welded it up as much as possible admitadly not a perfect seal as you cant get to

all of it but that is the fun bit. On the car now when you take your foot of the gas you get a reasonably loud bang as the air is able to get pulled

in and it dosent half make the boy racers jelouse when on a trackday they all think it's a cossie turbo. They really are dissapointed when they

realise it's a 1300 xflow with 90 bhp that just passed them. Seriously tho just weld it up taking care that it's all positioned

correctly.

cheers matt

NS Dev - 22/8/06 at 11:44 AM

.....................and check the can you are using. A decent system will not blow very much even if not sealed perfectly. As procomp says the most

clear sign is actually on the overrun when it draws air in.

Usually systems that keep blowing have too much backpressure

gingerprince - 22/8/06 at 06:01 PM

I am running a fairly restictive exhaust, but that was the price to pay to get the 'blade quiet enough to use on track!

Want to avoid any welding if possible, mainly because I don't have one

However I did have a cunning plan today. The fundamental problem is that I can't clamp the tubes. However there is gap to get a clamp around 2

pipes each, but obviously that'll just oval the pipes. However if I put in a wedge or something (like in the picture below) this should apply

pressure to all sides of the pipes and allow them to be tightened.

See picture below: -

Basically 2 ideas. Top one uses 2 wedges of steel/ally, bottom one uses some tube-section (or solid round) (though slightly larger diameter than in

the picture, this is just what i had lying round).

Then a couple of slits in the pipes and jubilee clips around each pair should hopefully make a tight fit.

Thoughts? I'd rather go for the bottom idea because it's a lot easier to do  . but if the top one seems miles better I'll go for that

one.

. but if the top one seems miles better I'll go for that

one.

Cheers, Sy

johnjulie - 22/8/06 at 10:15 PM

It is failing to seal because it's a poor fit, threfore it's just vibrating loose. On the Caterham, two of the primaries have a small piece

welded on that meets two similar pieces on the collector. They are then bolted together. I've also seen a few that use a couple of springs fixed

onto small plates on each side pulling them together under tension.

Silicone usually seals, the excess will get blown out, but it should still seal. Give the inside pipes a good coat, then slip the collector over

them.

You could also take your primaries to a good exhaust fitter that has a tool to open out the ends slightly, giving you a better fit.

www.scparts.co.uk sell such a tool, called a Spreader, it has three different sized expanders, not sure of the sizes. Only £38.

Cheers John

[Edited on 22/8/06 by johnjulie]

[Edited on 22/8/06 by johnjulie]

02GF74 - 23/8/06 at 07:16 AM

the second photo would be quick and easy to do.

I still think you need to look at a way of securing the 2 parts so that move as one - it seems the movement of one relative to the other is cuasing

them to come apart and force sealant out too.

if you are able to enlage the pipe going in and put a very tiny taper on the pipes that it goes into then that'll do it but not easy to do.

procomp - 23/8/06 at 08:22 AM

Hi unless they are a verry good fit together tying them together with split pins lockwire or springs will all fail a fter a short time due to the

vibration where the new parts welded to the pipes are and somtimes depending on the weld departs company with a piece of the pipe as well leaving you

with a even bigger problem.

Whithout welding best sugestion so far is to get the pipes flared out to be a better fit .

cheers matt