X-flow cooling AGAIN

scutter - 12/6/06 at 06:15 PM

After covering 500 miles this weekend( very indirect route to brands), My new cooling set up doesn't seem to be cutting the mustard as it were,

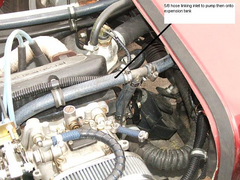

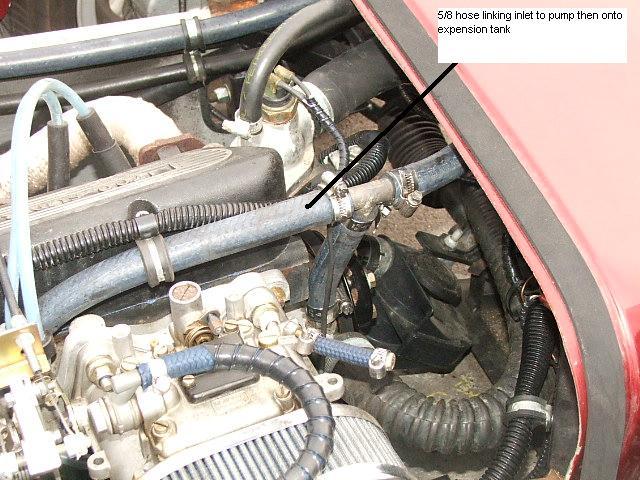

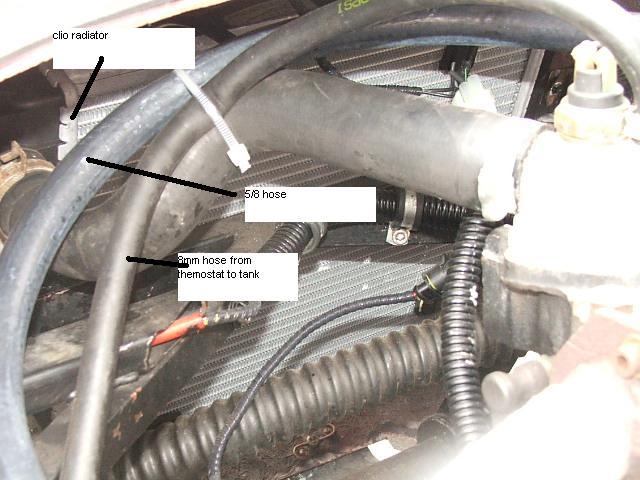

Can anyone spot any problems with the pic's below.

I have a rover expansion tank, clio radiator, Xflow engine of course and no heater fitted.

The loop form inlet manifold to pump is where i've plumbed in the tank, the 8mm pipe off the top of the thermostat housing goes to the smaller

fitting on the tank. The system is fully bleed with water coming out of the rad bleed point and the 8mm fitting on the housing when filled from the

tank itself.

Symptoms are the pressure cap steams like an old kettle when hot and most of the coolant ends up in the passenger footwell!!

Yes before anyone says the battery is being moved, it's staying there until the new cooling is proved.

Many thanks Dan.

inlet plumbing

into the rad area

again into the rad

[img][/img]

rusty nuts - 12/6/06 at 06:47 PM

Looking at your piccies I see the bleed pipe from the thermostat housing is attached to the outer chassis rail in engine bay which is lower than the

outlet . May be worth fitting a bleed valve at the highest point or removing the fan switch when filling cooling system . May also be worth fitting a

bleed valve at the tee piece above the pump , remember that air will rise to the highest point , pump may? be able to force the air to the header tank

but it should be easier to bleed from highest point . Also Red Line Water Wetter will drop the temperature by about 20 degrees which may help ?

theconrodkid - 12/6/06 at 07:09 PM

you have the header feeding into/from the heater outlet,maybe the pump is pushing water into header instead of round rad,water being like most

things.ie lazy,will find the easiest route

britishtrident - 12/6/06 at 08:15 PM

I suspect it is airlocking at the thermostat

Try drilling a 1/8" hole in the thermostat valve plate.

[Edited on 12/6/06 by britishtrident]

paulf - 12/6/06 at 09:38 PM

Its almost the same as my set up except that I ran the 5/8 pipe from the header tank to below the inlet manifold and then onto the bottom hose via a

Tee peice my pump has no small pipe as its from a FWD car.

Maybe the hose from tank to pump needs to be lower as it appears to be least as high as the header tank where it runs along the top of the engine and

could be air locking.

Paul.

Ham - 13/6/06 at 06:55 AM

Does the feed from the header tank tee off at the Inlet manifold?

My tank is teed off at the manifold and then connects to the small pump inlet - seems fine.

JimSpencer - 13/6/06 at 11:40 AM

Had a similar problem.

Simplified it all, by:-

Fitting an XR2 thermostat housing, the one with the filler cap on top.

Blanking plug on inlet manifold.

Then just a pipe from overflow to catch tank

Much much simplier and if you're not going to run a heater it works fine.

Ham - 13/6/06 at 12:22 PM

Problem there is that with the manifold connection plugged, when the thermostat is closed, surely there will be no circulation?

It is my understanding that the manifold outlet allows circulation untill the thermostat opens. ???

MikeR - 13/6/06 at 01:02 PM

that was my understanding. If you have a properly fitted pressurised header then there is no reason that the water pump should be pumping into the

header - where would it go? down the 8mm tube to the overflow?

(i've got basically teh same setup but haven't tried it yet - although mine 't's a lot closer to the pump - at exactly the same

height the pipe comes out of the inlet manifold.)

JimSpencer - 13/6/06 at 02:58 PM

Sorry my mistake... should have clarified

XR2 Thermostat housing... no thermostat in it though

Heard about doing it this way, had a shufty at a formula ford in the back of my garage yup done the same way. So gave it a bash worked fine, saved

loads of plumbing and about 7kgs too.

scutter - 18/6/06 at 11:25 AM

OK, i've unclipped the pipework along the chassis rail and propped the tank on a broom handle to make it the highest point in the system, I then

filled the system with the radiator vent screwed out and the fan switch removed, the thermostat has been checked and it already has a hole in it. Yet

still the system blows like a bas***d.

Now there is a bleed point being welded up at work, so i can bleed the system with all the pipework in the correct place. So what's left, could

the pressure cap be faulty or should i close off the manifold loop with the new bleed point in it and plumb the header into the bottm rad hose?

Also what's to stop the system drawing in air through the upper expension tank hose via the vented cap?

Thanks to all those that have helped so far, because this is getting in my nerves as i can't do more than 5 miles without it boiling over on

me.

ATB Dan.

[img][/img]

rusty nuts - 18/6/06 at 06:32 PM

I think it would be worth testing for head gasket failure using either a block testing kit or possibly an exhaust emissions tester (look for high

hydrocarbons ).

MikeR - 18/6/06 at 06:37 PM

I'm about to start mine with pretty much the same setup. I'll let you know how i get on.

(would have fired her up today except of all the things to lose - i lost a fan belt. Had 2, two years ago, now i can't find one  )

)

Syd Bridge - 18/6/06 at 06:51 PM

A good start would be to run the small hose from the t'stat housing direct over the top of the engine to the top tank.

Other common cause is no exit for cooling air. No airflow...no cooling.

Cheers,

Syd.

Edit....That small hose will bleed the air and any vapours that get into the system, ONLY if it is kept above the T'stat outlet all the way to

the top tank. That way the gasses can escape direct to the tank. No air/vapour locks Comprende?

The bigger hose to the bottom of the top tank can stay where it is.

[Edited on 18/6/06 by Syd Bridge]

scutter - 21/6/06 at 04:42 PM

Syd having read your post about 5 time I finally read it fully and have replaced the 8mm hose with a piece of rigid pipe and wouldn't you know

almost cured it in one go, a quick trip to the motor factors for a new filler cap and jobs a goodun.

Many thanks to all that have helped. just 1/2 a doz. oil leaks to cure and were there.

ATB Dan.

)

)