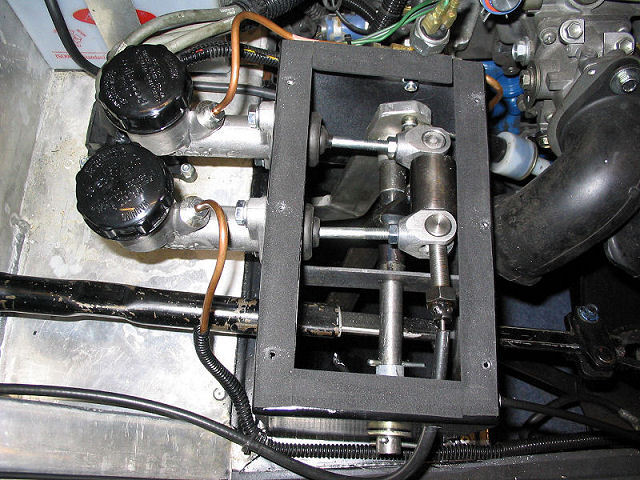

I had an idea the cam timing was not correct and assumed the variable inlet cam wasn't advancing correctly. Sure enough by disconnecting the variater solenoid wires power went straight up to 131BHP and the engine was willing to rev again!

So why was the engine loosing power with the inlet cam advanced. Simple the cam belt had slipped and both the inlet and exhaust cam were already advanced. So when the OMEX ECU switched the solenoid the inlet cam advanced another 10-15 deg of timing. Not good for power thats for sure. Thankfully only the fueling was out and we couldn't detect any pinking or detonation!

After a little more investigation it seems the self adjusting tension pulley was a littel loose and must have let the cam belt jump a couple of teeth. Thankfully no damage done so if you have a 20V 4AGE I would check your cam belt tensioner ASAP.

Anyway now the cam timing was correct so we reconnected the inlet cam solenoid and did another power run. 144 BHP @ 7800RPM and I'm feeling much better. The fueling was a little on the lean side so Brian (the garage owner) and myself had a littel play with the OMEX mapping software. Neither of us have actually mapped a car with the OMEX software but Brian has used several other packages and I've looked over the shoulder of the usual operator who wasn't available at the time. Between us we get the fueling back to the correct lambda readings

We're not finished yet though as I've been told a littel tip on tuning these engines. Basically you start the engine with a retarded cam, at approx 4500 RPM the inlet cam is advanced and usually that is it till red line. The trick is to retard the cam again at approx 7000 RPM and "bob's your vey close relative" 153 BHP @ 7800 RPM !!

So that little trick gained 6 BHP over my previous best on these rollers and the car is going great

My engine is a 1600cc Toyota "blacktop" 20V 4AGE, factory individual throttle bodies and a Fidanza ali flywheel all controlled by an OMEX 710 ECU. The rollers were a SUN eddie current chassis dyno.

[Edited on 12/4/06 by bimbleuk]