... been busy doing a spot of welding and drilling...

02GF74 - 4/1/06 at 10:38 AM

I've sorted out the accelerator cable by making small brass ferrules (?) to hold the cable in place and a small adjustable bump stop so the pedal

rests in position. The bump stop has a buffer made from a piece of radiator hose!

accelerator pedal bump stop

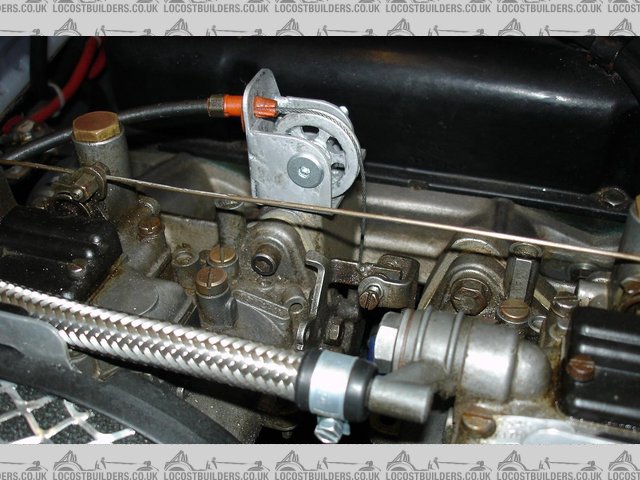

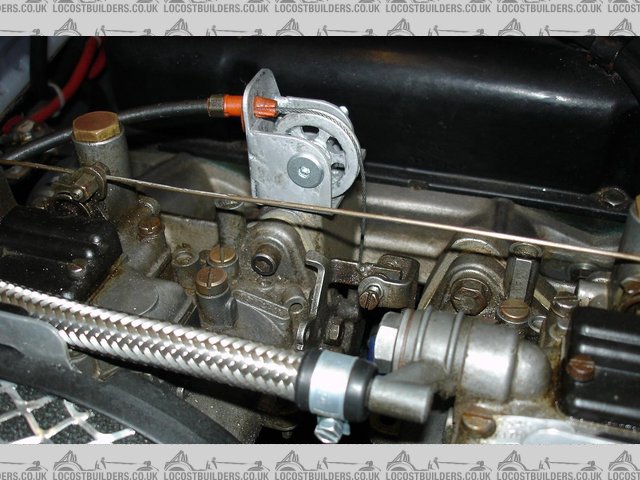

To reduce the angle through which the accelerator cable goes, I made a small pulley for the cable.

accelerator cable pulley

I don't forsee any problems with this but all linkages I have seen use a rod; my set up has a cable running in a curved guide.

If I get enthusiastic I might look into replacing the pulley with a pivoting lever to pull on a rod, later ....

Just wondering if anyone has comments on the pulley system?

Lastly I welded two plates to the side of the chasis for the ignition coil. It now sits in an air flow past the raditor so it should be happier as

previously it was bolted to the cylinder head!!!!?!?!?!?

[img][/img]

Bluemoon - 4/1/06 at 10:55 AM

Bit of a kink where the cable goes through the bluckhead (next to master cyclinder)... Might be and idea to ensure this is always straight....

Schrodinger - 4/1/06 at 12:50 PM

you might find that the ratio between pedal movement and the opening of the carb is a bit high and make controling the engine speed a bit

difficult.

Keith

Suffolk

02GF74 - 4/1/06 at 01:54 PM

quote:

Originally posted by Schrodinger

you might find that the ratio between pedal movement and the opening of the carb is a bit high and make controling the engine speed a bit

difficult.

interesting; I did wonder about this - all to do with lever length!!

So how much pedal travel is there typically for full carb range? Can people post up the distance their acc. pedal moves for full range?

[Edited on 4/1/06 by 02GF74]

RoadkillUK - 4/1/06 at 06:48 PM

I'd consider a split pin over the green wire

stevebubs - 4/1/06 at 06:59 PM

I wouldn't be surprised if the cable snaps where it's welded to the linkage as this little bit will be constantly flexing on a short

radius...a better, more flexible solution would be better....especially one that means you can change the cable at the roadside in the middle of

France after a quick trip to Euromarche...

[Edited on 4/1/06 by stevebubs]

owelly - 4/1/06 at 10:06 PM

By using a rod linkage, it usually means that the further the pedal is pressed the less the linkage moves. If that makes sense. The lever goes

'over center' so moves the butterflies less.

MikeRJ - 5/1/06 at 08:28 AM

quote:

Originally posted by stevebubs

I wouldn't be surprised if the cable snaps where it's welded to the linkage as this little bit will be constantly flexing on a short

radius...a better,

I wasn't sure if the cable had been welded in that picture or not. If it is welded, it will snap with 100% certainty.

RazMan - 5/1/06 at 08:53 AM

Perhaps one of these would work?

From Rally Design

02GF74 - 5/1/06 at 10:11 AM

cheers for comments

>>> Bit of a kink where the cable goes through the bluckhead (next to master cyclinder)... Might be and idea to ensure this is always

straight....

yeah, I cut the cable too short; will need to make a slightly longer bulkhead connector.

>>>> you might find that the ratio between pedal movement and the opening of the carb is a bit high and make controling the engine speed a

bit difficult.

no probs. there; quite the opposite in fact; compared with volvo and LR and distances of pedal travel are:

V = 60 mm

LR = 57 mm

K = 83!!

>>> I'd consider a split pin over the green wire

ok

>>>> I wouldn't be surprised if the cable snaps where it's welded to the linkage as this little bit will be constantly flexing

on a short radius...a better, more flexible solution would be better....

the weld is for a small piece of metal to connect linkage to front carb not the wire. The wire passes behind it and round a circular guide

- photo makes it look like wire is welded.

The pulley was made reasonably big to avoid having a tight bend for the wire. I will be looking to replace the circular guide so the throttle can be

operate by a rod and lever that would also be asjustable to set the ratio so reduce pedal travel a bit but that is for later..,,.... .